Matte BOPP aluminum laminated film for labels and production technology thereof

An aluminized film and matte technology, which is applied in the field of film manufacturing, can solve the problems of unstable action time, insufficient mechanical properties of the film, and fading matte effect, so as to improve the matte effect, save the coating process, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

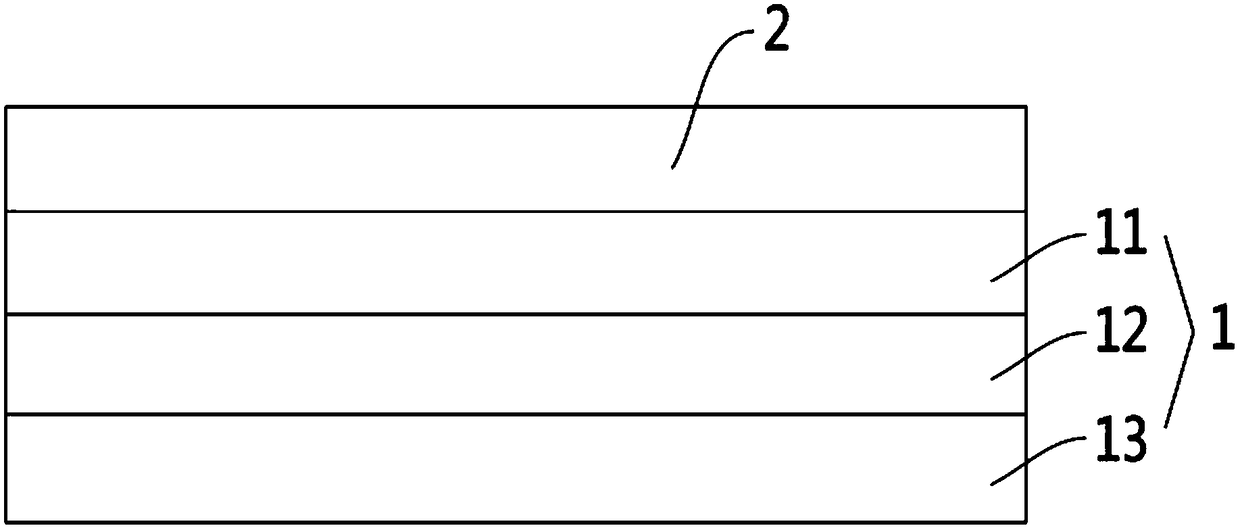

[0029] A / (90% matte masterbatch+10%HDPE) / C / (96%PP+4%nano-SiO 2 ), layer A is an aluminum layer with a thickness of 450 angstroms, layer B is an aluminum-coated layer, and is composed of 90% matte masterbatch and 10% HDPE, with a thickness ratio of 10%; layer C is an intermediate layer with a thickness ratio of 80%; C layer is heat seal layer, made of 96% PP and 4% nano-SiO 2 Composition, the thickness ratio is 10%.

[0030] By adopting the above technical scheme, the obtained matte VMBOPP film has a haze of 25%.

Embodiment 2

[0032] A / (85% matte masterbatch+15%HDPE) / C / (96%PP+4%nano-SiO 2 ), layer A is an aluminum layer with a thickness of 450 angstroms, and layer B is an aluminum-coated layer composed of 85% matte masterbatch and 15% HDPE with a thickness ratio of 10%; layer C is an intermediate layer with a thickness ratio of 80%; C layer is heat seal layer, made of 96% PP and 4% nano-SiO 2 Composition, the thickness ratio is 10%.

[0033] By adopting the above technical scheme, the obtained matte VMBOPP film has a haze of 40%.

Embodiment 3

[0035] A / (80% matte masterbatch+20%HDPE) / C / (96%PP+4%nano-SiO 2 ), layer A is an aluminum layer with a thickness of 450 angstroms, layer B is an aluminum-coated layer, and is composed of 80% matte masterbatch and 20% HDPE, with a thickness ratio of 10%; layer C is an intermediate layer with a thickness ratio of 80%; C layer is heat seal layer, made of 96% PP and 4% nano-SiO 2 Composition, the thickness ratio is 10%.

[0036] By adopting the above technical scheme, the obtained matte VMBOPP film has a haze of 65%.

[0037] A kind of production technology of matte BOPP aluminized film for label, comprises the steps:

[0038] 1) First, the matte BOPP base film (including corona layer, intermediate layer and heat-sealing layer) is extruded by an extruder;

[0039] 2) Prepare the matte BOPP base film by biaxial stretching;

[0040] 3) Finally, place the upper surface of the matte BOPP base film at 10 -4 Vacuum aluminum plating is carried out at a vacuum degree above mbar.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com