Patents

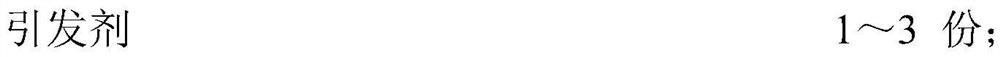

Literature

30results about How to "Achieve a matte finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-doodling aqueous interior wall paint and preparation method thereof

InactiveCN104059513ARealize the scattering effectAnti-graffiti effect is obviousPolyurea/polyurethane coatingsCelluloseMildew

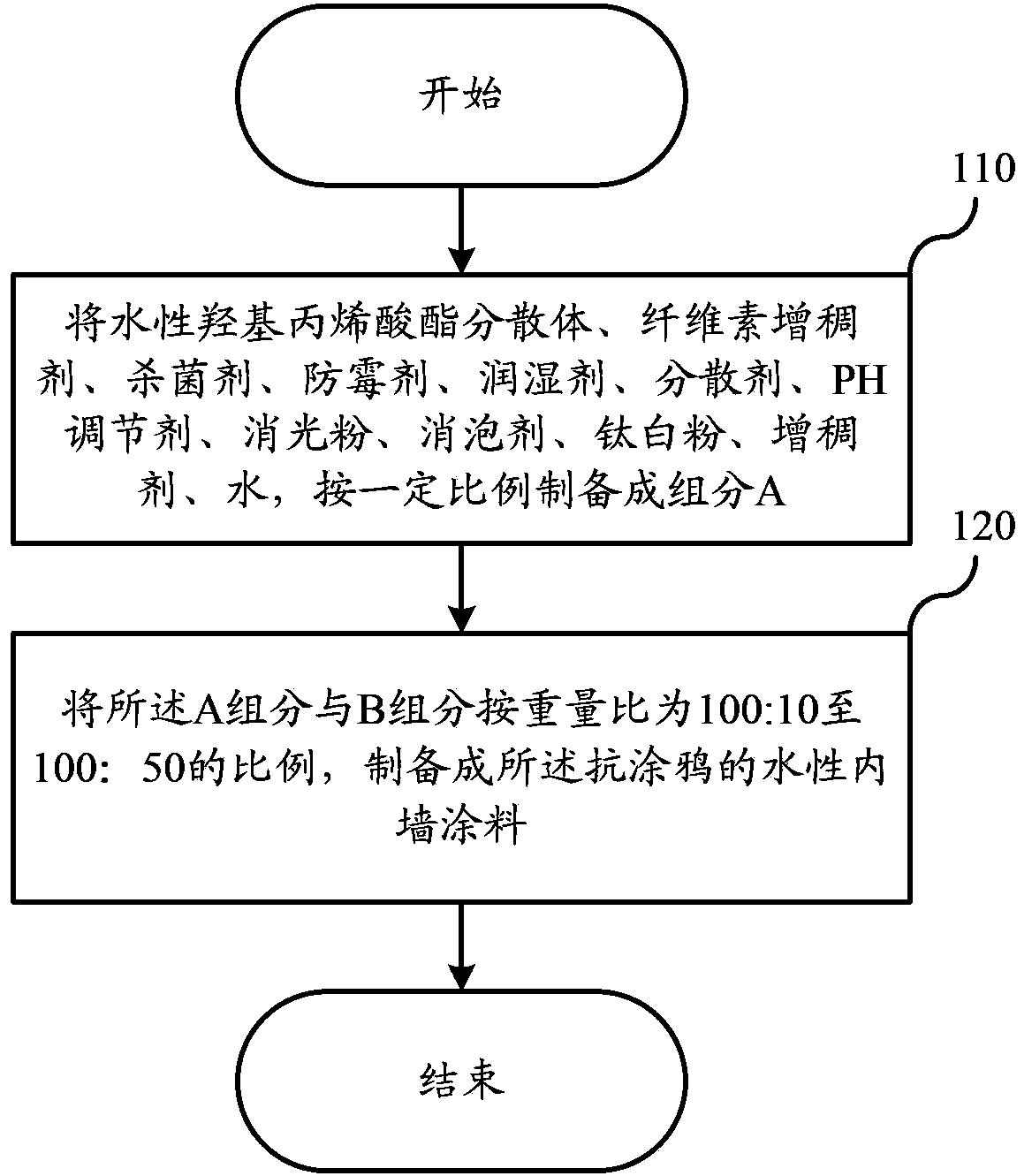

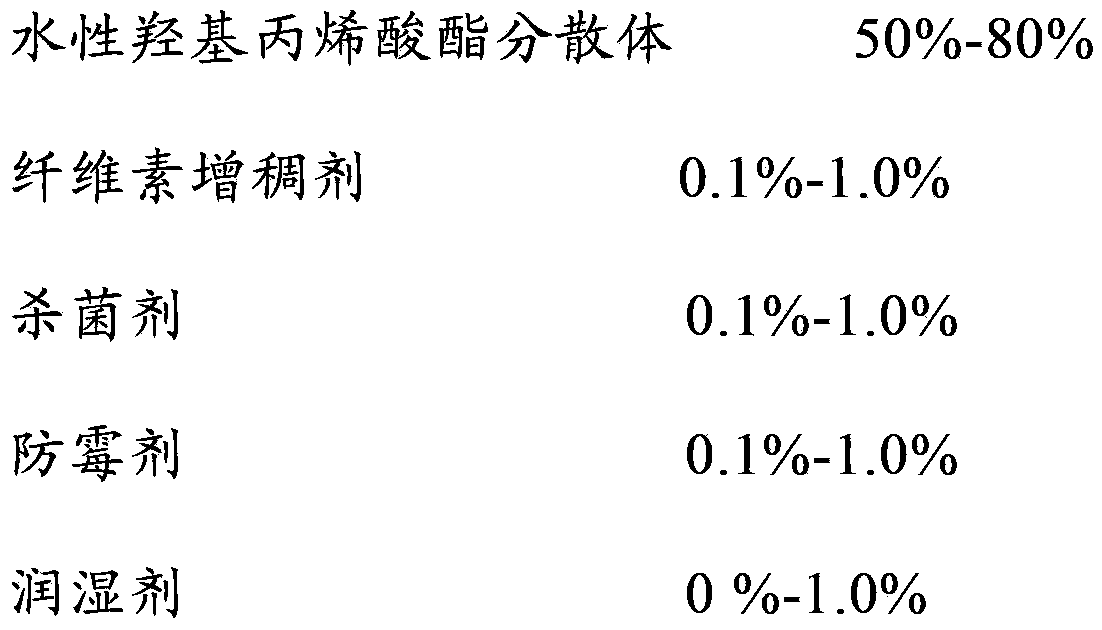

The invention relates to the technical field of paint, and discloses an anti-doodling aqueous interior wall paint and a preparation method thereof. In the invention, an aqueous hydroxyl acrylate resin dispersion, a cellulose thickener, a bactericide, a mildew inhibitor, a wetting agent, a dispersant, a PH conditioning agent, a flatting powder, an antifoaming agent, titanium dioxide, a thickening agent and water are prepared to a component A according to the proportion, the component A and hydrophilic aliphatic polyisocyanate being as an component B are combined for usage, paint film surface can be effectively enclosed, thereby various kinds of spots can not penetrate in the surface of the paint film so that moisture cloth is easily used for wiping without any trace, the test proves that the anti-doodling aqueous interior wall paint has obvious anti-doodling effect. The prepared aqueous interior wall paint can meet the requirements of full hydration, the prepared paint contains no harmful solvent and has advantages of high environmental protection, compared with current anti-doodling paint, and the cost is low. In addition, the production technology is simple, construction is convenient, construction cycle is short, and the anti-doodling aqueous interior wall paint is beautiful and durable.

Owner:境洁环保科技(上海)有限公司

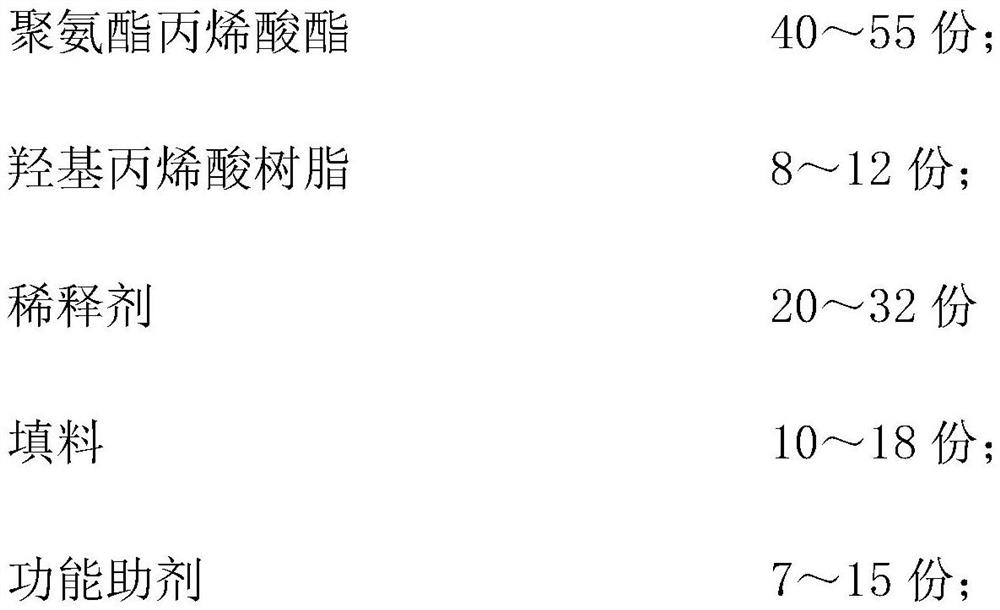

Non-treatment frosted varnish ink for PET (polyethylene terephthalate) film gravure

ActiveCN104861775AImprove aestheticsAchieve freedom of controlInksWaxPolyethylene terephthalate glycol

The invention discloses non-treatment frosted varnish ink for PET (polyethylene terephthalate) film gravure. The ink is characterized by comprising varnish, a diluent and a curing agent in the weight ratio being 10:(4-18):0.5, wherein the varnish comprises components in percentage by weight as follows: 25%-40% of a polyurethane resin liquid, 3%-7% of butyl acetate, 8%-12% of ethyl acetate, 8%-25% of an inorganic pigment, 1%-3% of PE wax powder, 2%-4% of a dispersing agent, 15%-20% of a modified material and 20%-35% of n-propyl acetate. With the adoption of the ink prepared with the formula, a common PET light film can be locally matted or completely matted through printing, and the beauty of a product is improved; the matt degree of the product is freely controlled to range from 2 degrees to 15 degrees through adjustment of the addition proportion of the diluent of the varnish ink and the depth of a printing plate; the matt effect is realized through the common PET film, the cost is low, and preparation is convenient.

Owner:DONGCHANG IND LINHAI CO LTD

Finish-coat-free matte water-based colored paint and preparation method thereof

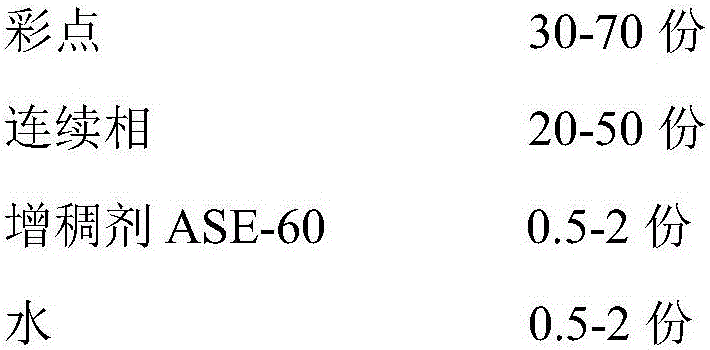

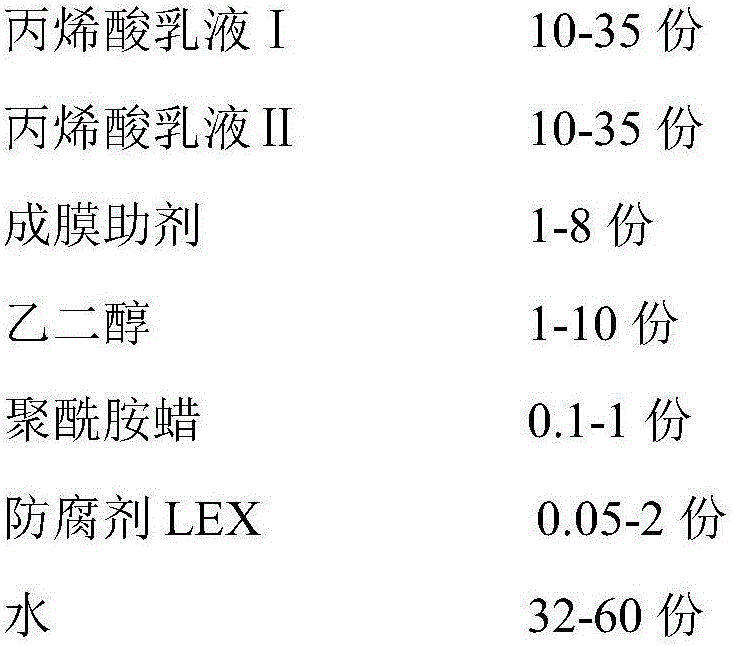

The invention relates to finish-coat-free matte water-based colored paint and a preparation method thereof and belongs to the field of building paint. According to the paint provided by the invention, styrene-acrylic emulsion, a phosphate type dispersant, cellulose, a colloidal solution and polyamide wax have a common effect so that color points are stable and the suspension property is high; COASOL and two types of silicone modified acrylic emulsion with obvious particle size difference, and the polyamide wax are used as continuous phases of multi-colored paint; compared with traditional finish-coat matte water-based multi-colored paint, matting powder does not need to be added into the multi-colored paint and matte finish-coat varnish does not need to be brushed, and the matting and vintage effects can also be realized; the finish-coat-free matte water-based colored paint has excellent water resistance, water white resistance and storage stability; the disadvantages of traditional finish-coat matte water-in-water multi-colored paint are successfully overcome; the finish-coat-free matte water-based colored paint is applicable to non-plane matte water-based water-in-water paint and finish-coat-free matte multi-colored paint and the like.

Owner:成都巴德富科技有限公司

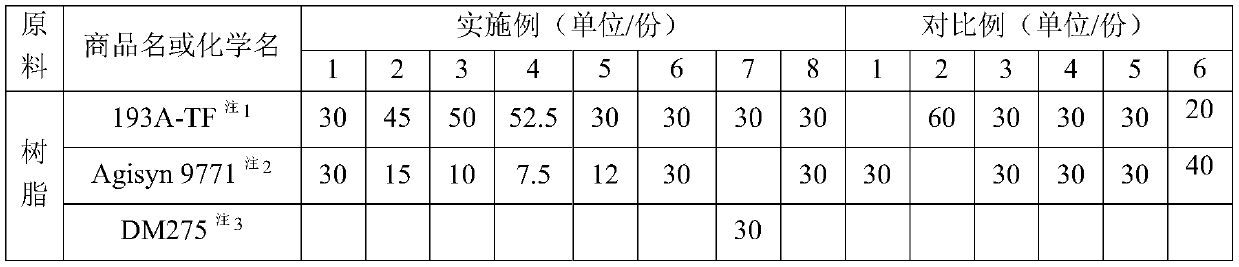

Matting powder-free ultra-matte skin feeling UV coating and preparation and curing method thereof

InactiveCN111057452AAchieve a matte skin feelNo pollution in the processAntifouling/underwater paintsPretreated surfacesPolymer scienceAcrylic resin

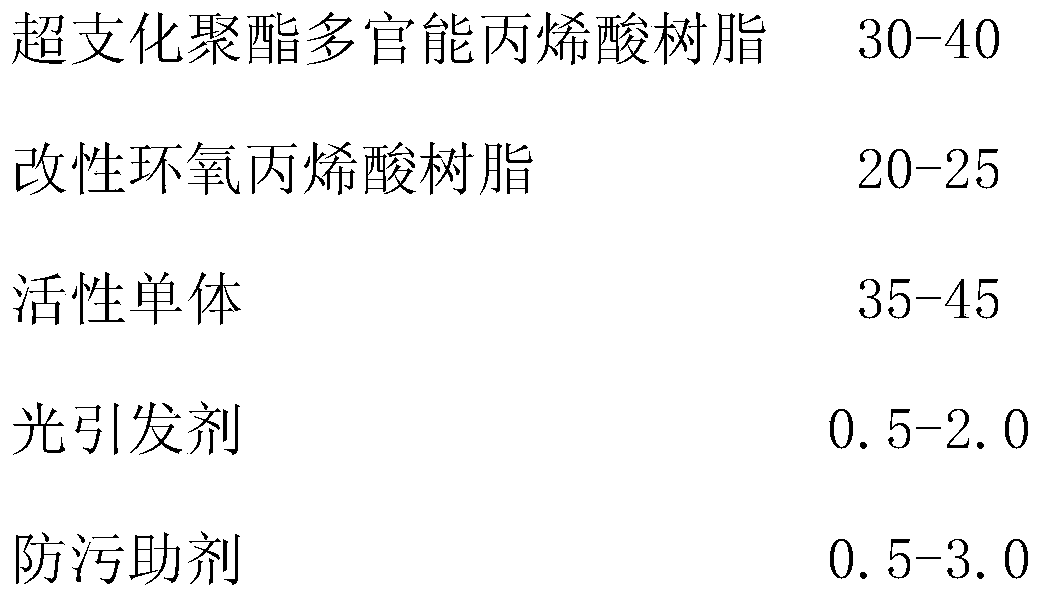

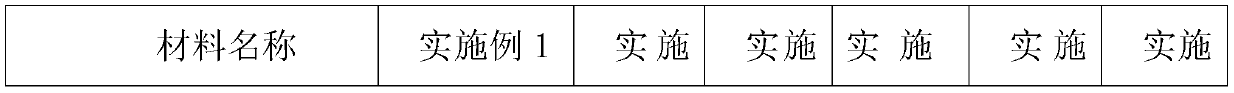

The invention relates to a matting powder-free ultra-matte skin feeling UV coating and a preparation and a curing method thereof. The formula comprises the following components in parts by weight: 30to 40 parts of hyperbranched polyester multifunctional acrylic resin, 20 to 25 parts of modified epoxy acrylic resin, 35 to 45 parts of an active monomer, 0.5 to 2.0 parts of a photoinitiator and 0.5to 3.0 parts of an antifouling auxiliary agent. The raw materials are mixed and stirred to obtain the matting powder-free ultra-matte skin feeling UV coating. The coating prepared by the invention ismainly applied to wood material surface ultra-matte skin feeling coating and the like; the manufacturing process is simple, and a gallium lamp, a 172nm excimer lamp, a nitrogen oxygen-expelling lamp and a mercury lamp UV light source are adopted; due to the fact that the ultraviolet output energy of the 172nm excimer lamp is concentrated, the ultraviolet output intensity is high and can reach 100mW / cm<2>, expensive matte powder and skin feeling auxiliaries are not needed, after a coating film is cured, the gloss of matte is below 2 degrees (60 degrees), and the coating film is good in skin feeling, stain-resistant and scratch-resistant.

Owner:CHANGZHOU WEIXING DECORATIVE MATERIALS +1

Matte PVC decorative film capable of reducing surface brightness of product

InactiveCN107513233AImprove stain resistanceImprove the problem of poor stain resistanceCoatingsSurface brightnessStain

The invention relates to a matte PVC decorative film capable of reducing the surface brightness of a product. The matte PVC decorative film is prepared from the following components in parts by weight: 100 to 120 parts of PVC resin powder, 15 to 100 parts of matting powder, 8 to 12 parts of calcium powder, 3 to 5 parts of feeling agent, 0.3 to 0.5 part of titanium dioxide, 20 to 30 parts of plasticizer, 3 to 3.5 parts of barium-zinc stabilizing agent, 0.2 to 0.4 part of internal lubricant, 2 to 4 parts of processing aid, and 1 to 2 parts of stain resistant aid. According to a standard GB / T17657-2013, common contaminants (acetone and black coffee) are used to carry out a stain resistance test; the test result shows that the provided matte PVC decorative film has a better stain resistant performance, compared with a conventional matte PVC decorative film; and the problem that the stain resistant performance of the conventional PVC decorative film is solved. At the same time, the matte PVC decorative film has the advantages of excellent matte property, scratch resistance, stain resistance, easiness for scrubbing, and soft feeling, and can be well matched with other decorative materials.

Owner:FOSHAN TIANJIN PLASTICS

Water-based two-component polyurethane matte coating as well as preparation method and application thereof

ActiveCN113088174AAvoid powder settlingLow costPolyurea/polyurethane coatingsDefoaming AgentsEmulsion

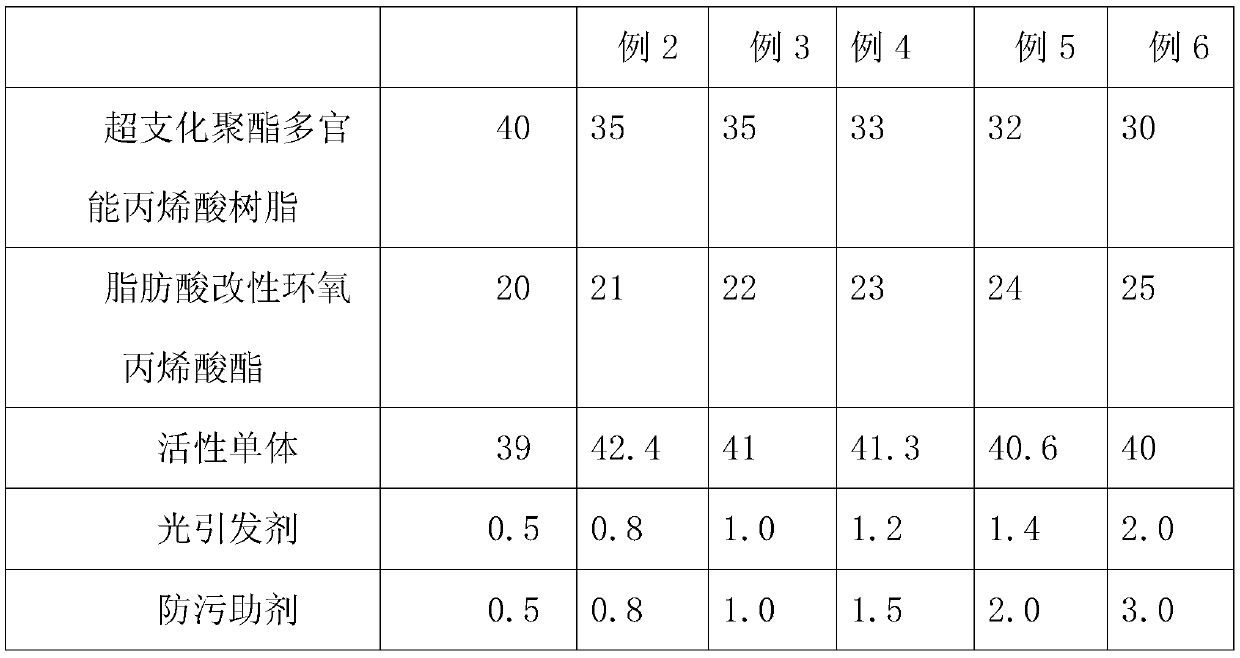

The invention provides a water-based two-component polyurethane matte coating as well as a preparation method and application thereof. The water-based two-component polyurethane matte coating comprises a component A and a component B. The component A is prepared from the following raw materials in parts by weight: 60-90 parts of hydroxyl acrylate emulsion, 5-20 parts of deionized water, 0-30 parts of powder, 0.5-2.5 parts of a wetting dispersant, 0.2-2 parts of a thickening agent, 0.2-1 part of a defoaming agent, 0.5-1.5 parts of a preservative, and 0.2-2 parts of a coalescing agent; the component B is prepared from the following raw material in parts by weight: 0.1 to 5 parts of Covestro 307 water-based curing agent. The polyurethane matt coating disclosed by the invention can have a matt effect without additionally adding matting powder, the water resistance, permeability and stability of the coating can be greatly improved, and the polyurethane matt coating is suitable for the field of coatings.

Owner:DONGGUAN CTL NEW MATERIAL TECH

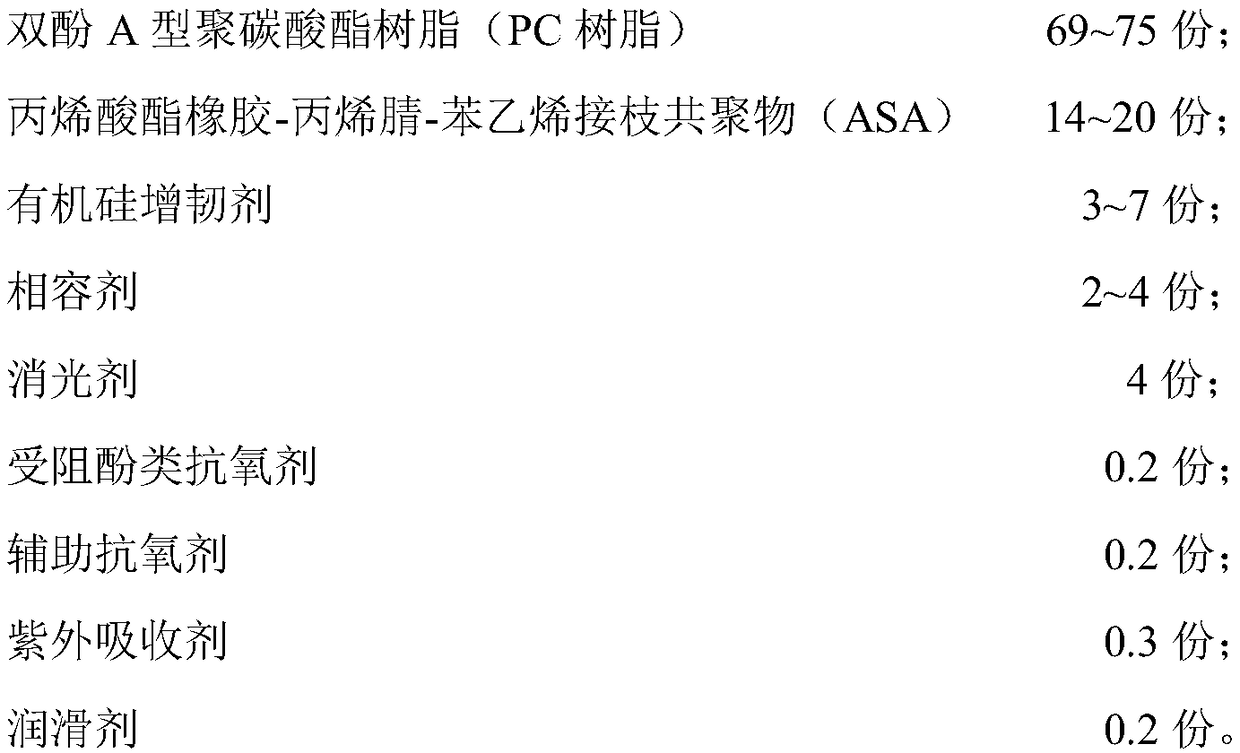

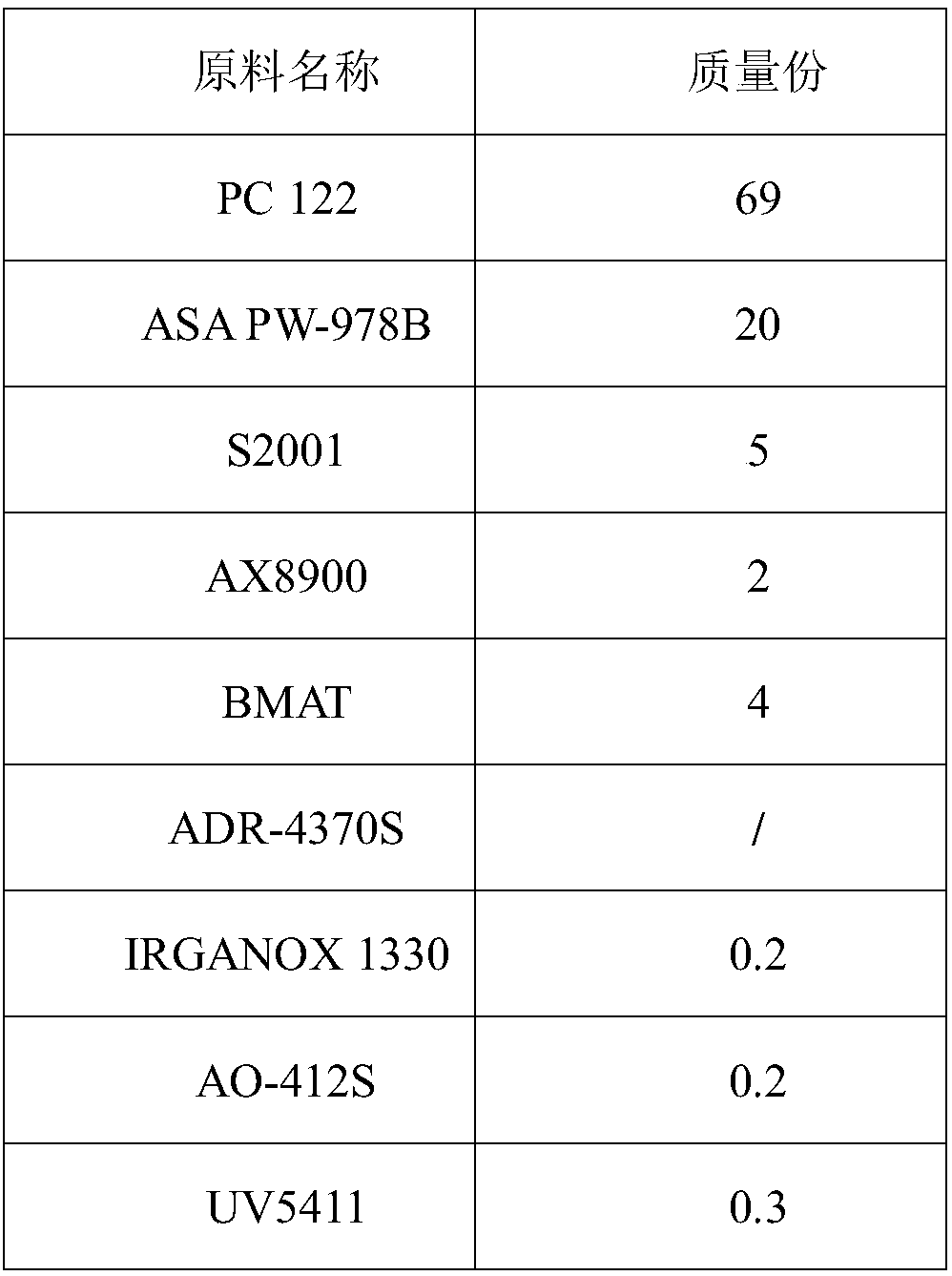

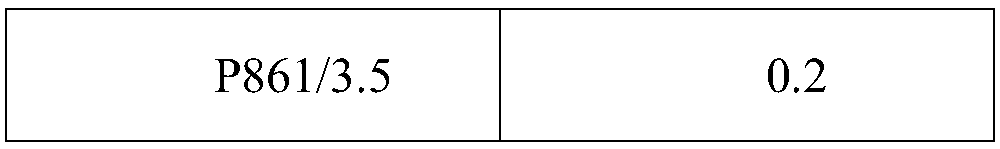

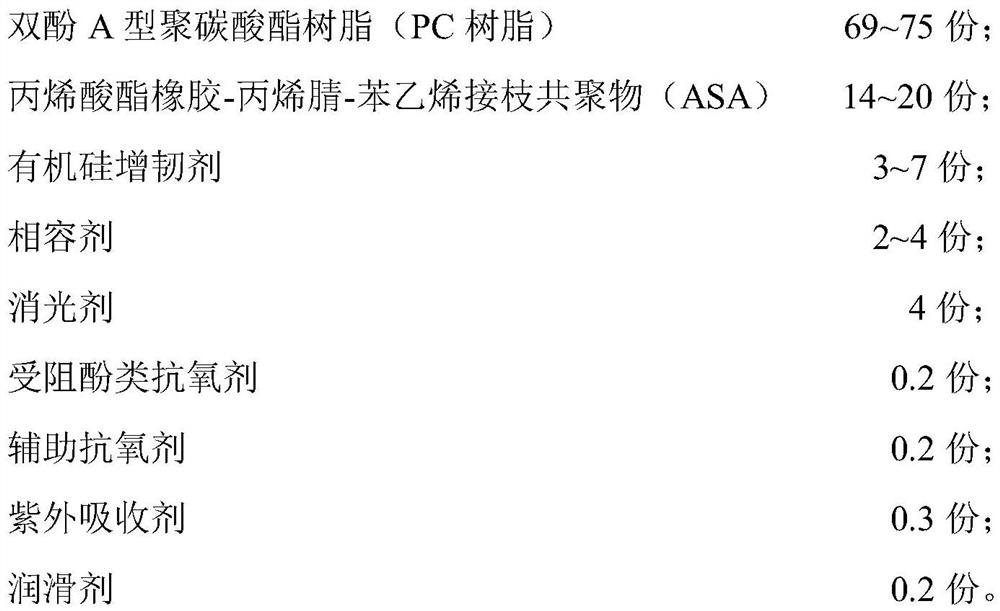

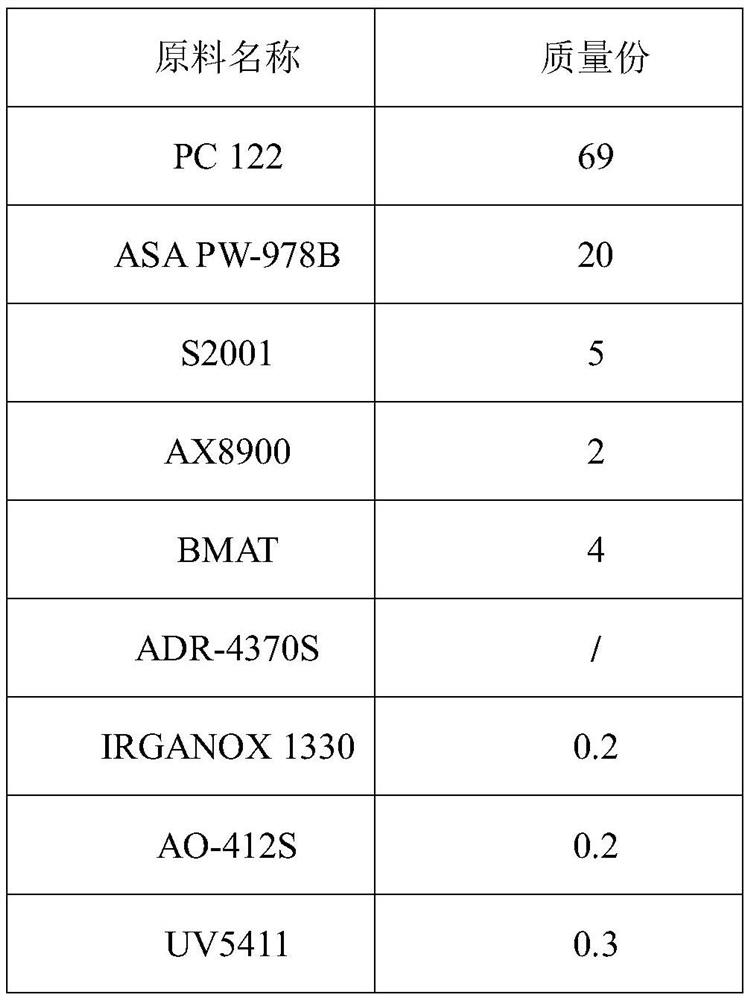

Weather-resisting matte PC/ASA alloy material

The invention discloses a weather-resisting matte PC / ASA alloy material. The weather-resisting matte PC / ASA alloy material is prepared from the following components in parts by weight: 69 to 75 partsof bisphenol A polycarbonate resin, 14 to 20 parts of acrylic rubber-acrylonitrile-styrene grafted copolymer, 3 to 7 parts of an organosilicone toughening agent, 2 to 4 parts of a compatilizer, 4 parts of a flatting agent, 0.2 part of a hindered phenol antioxidant, 0.2 part of an auxiliary antioxidant, 0.3 part of an ultraviolet absorbent and 0.2 part of a lubricant. The alloy material mainly takes the bisphenol A polycarbonate, an acrylic rubber body, acrylonitrile and a styrene grafted copolymer as main raw materials which are combined with the organosilicone toughening agent, an organic flatting agent, a high efficiency antioxidant, a special UV absorbent and other components, so that the matte fogging surface effect on the surface of the material is achieved by utilizing synergistic interaction of various components; the alloy material has the properties of weather resistance and high and cold resistance; meanwhile, the alloy material has excellent physical properties, can meet theoutdoor weather resistance requirements, and can be widely applied to automotive interior and exterior decoration, office equipment, communication equipment, outdoor lighting components and the like.

Owner:南京运昶高分子材料有限公司

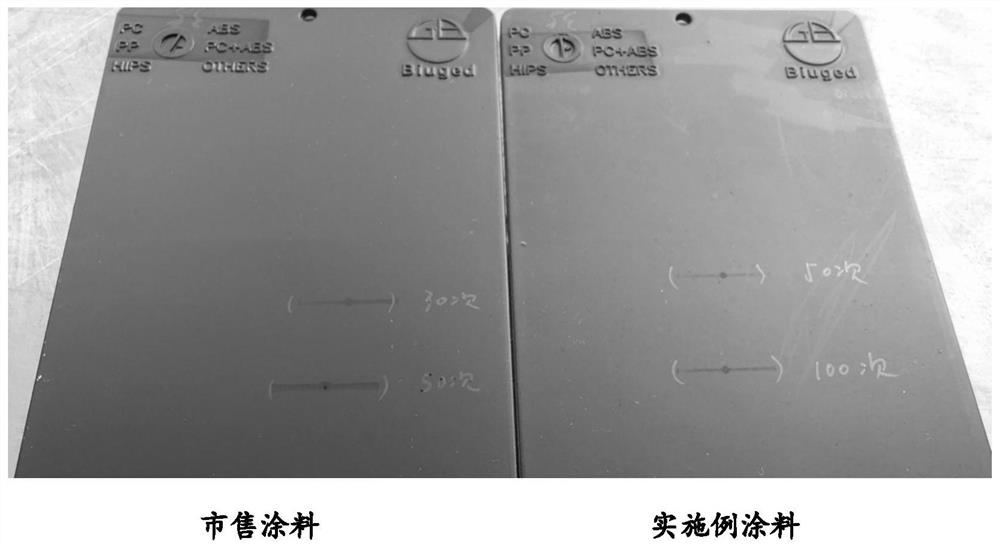

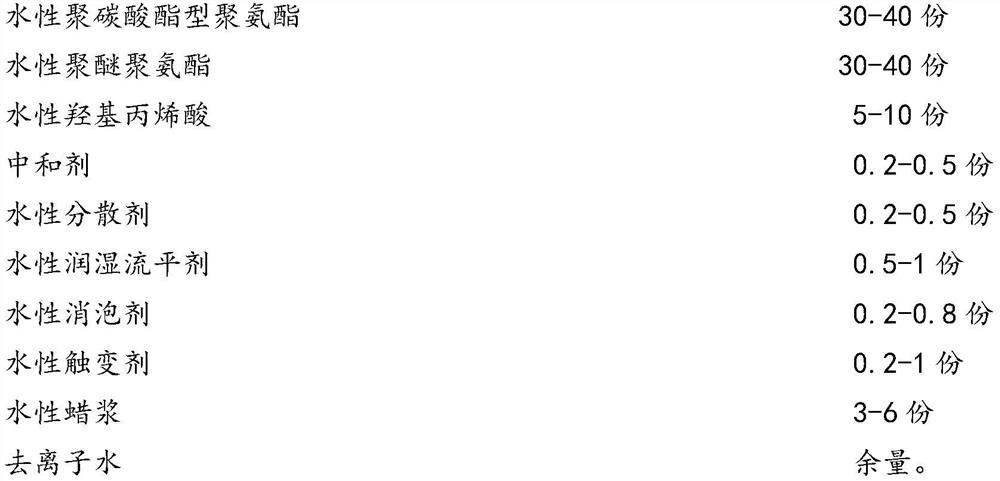

Plastic material based on high-wear-resistance water-based elastic coating

InactiveCN112029400AImprove wear resistanceGood extinction stabilityPolyurea/polyurethane coatingsPolyether polyurethanePlastic materials

The invention discloses a plastic material based on a high-wear-resistance water-based elastic coating. The plastic material is composed of a plastic substrate and a coating layer on the surface of the plastic substrate. The coating layer is prepared from the high-wear-resistance water-based elastic coating; the high-wear-resistance water-based elastic coating comprises an agent A and an agent B;the agent A comprises water-based polycarbonate polyurethane, water-based polyether polyurethane, water-based hydroxy acrylic acid, a neutralizer, a water-based dispersing agent, a water-based wettingleveling agent, a water-based defoamer, a water-based thixotropic agent, water-based wax slurry and deionized water; and the agent B comprises a curing agent and a diluent. According to the formula,the matte effect is achieved, the required matte effect can be achieved by adding little or even no matting powder into an elastic paint system, the matting stability of the system is better, the permeability of a paint film is good, the three kinds of resin serve as main bodies and are combined with a small amount of auxiliaries, and the effects that the paint film has the high abrasion resistance and meanwhile the hand feeling is excellent are achieved.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

Printing technology for cigarette low gloss white effect

InactiveCN110053378AAchieving Diversity RequirementsAchieve a matte finishDuplicating/marking methodsOther printing apparatusElectrical and Electronics engineeringGilding

The invention discloses a printing technology for the cigarette low gloss white effect. According to the technology, an image-text layer is subjected to low gloss bonding coverage through ink fountainlow gloss ink in the offset printing procedure, the colorful low gloss effect is achieved, meanwhile, it is guaranteed that a pattern is clear and visible, and color whitening and dimming in hard light and backlighting are avoided. Through gilding and screen printing, the appearance intersperse feeling of packaging boxes is further improved, the requirement for image-text diversification is met,and the requirements of medium-high-end consumption.

Owner:HUBEI CHINA TOBACCO IND +1

Scratch-resistant black ink for matte insulating high-shading electronic film

InactiveCN111500106ASolve the problem of non-scratchReduce usageInksThermal dilatationPolymer science

The invention relates to the technical field of fine chemical engineering, in particular to scratch-resistant black ink for a matte insulating high-shading electronic film, which is prepared from thefollowing raw materials in parts by weight: 60-70 parts of solvent, 1-2 parts of delustering agent, 1-2 parts of wetting dispersant, 3-6 parts of carbon black, 10-15 parts of polyurethane resin, 2-3 parts of thermal expansion microspheres and 3-6 parts of butyl glycidyl ether. According to the invention, the use of matt powder in the formula can be greatly reduced, the part protruding out of the ink film layer has excellent scratch resistance, and the problem that matt insulating black ink is not scratch-resistant can be well solved. Relatively good adhesive force can be achieved by using relatively small amount of resin. The problems of low insulativity and easy reverse adhesion of the original scheme can be solved. The resistance of the printed electronic film can be effectively improveddue to the facts that a plurality of tiny holes are generated between the first ink layer and the second ink layer due to unevenness and a large number of tiny holes caused by expansion microspheresexist in the ink layer. The ink consumption of customers can be saved, and the cost is saved.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

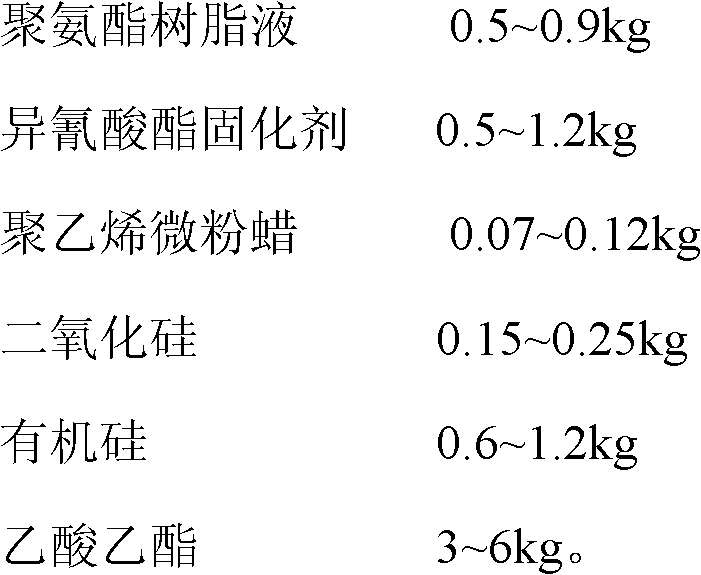

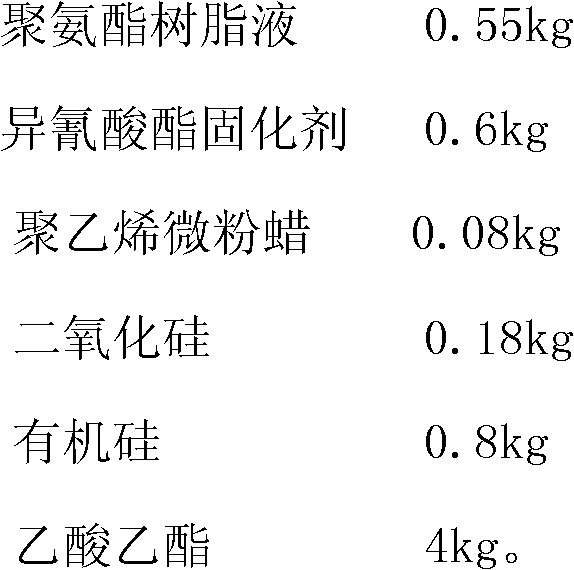

Total diffuse reflection matt coating material for thermal transfer and application and application method thereof

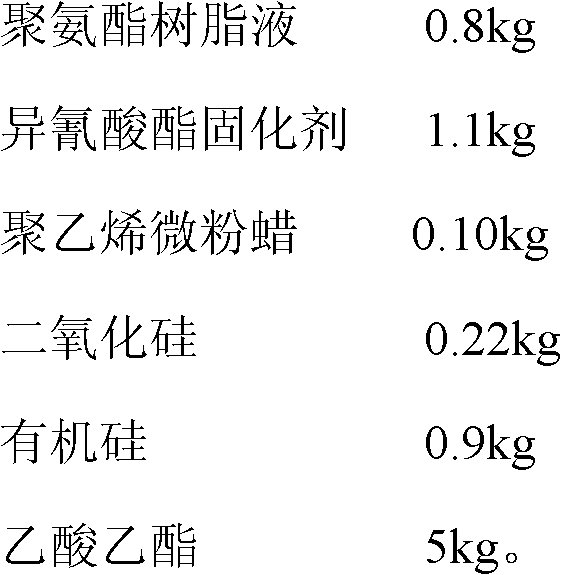

InactiveCN102690591AAchieving full diffuse reflectionAchieve a matte finishPolyurea/polyurethane coatingsSpecial surfacesPolyesterAcetic acid

The invention discloses a total diffuse reflection matt coating material for thermal transfer, which comprises the following components by weight: 0.5-0.9 kg of polyurethane resin liquid, 0.5-1.2 kg of isocyanate curing agents, 0.07-0.12 kg of polyethylene wax superfines, 0.15-0.25 kg of silica, 0.6-1.2 kg of organosilicon, and 3-6 kg of ethyl acetate. The invention also discloses its application and an application method. The advantages of the invention are that the matt material can realize total diffuse reflection and reach the effect of complete mattness; the coating liquid can be coated on a bright polyester film surface to form a total diffuse reflection highly-matt material, which can be used for producing various thermal transfer decoration materials.

Owner:嘉兴艾森压烫科技有限公司

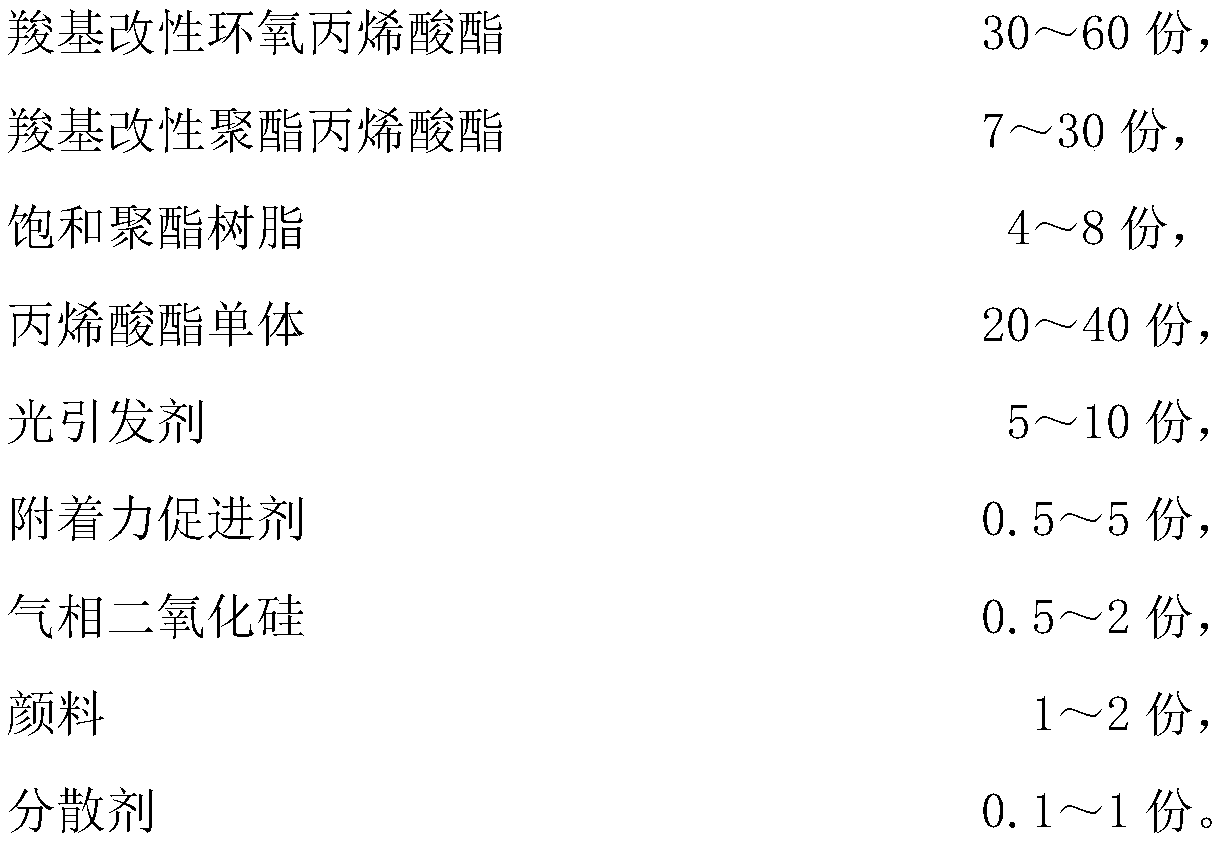

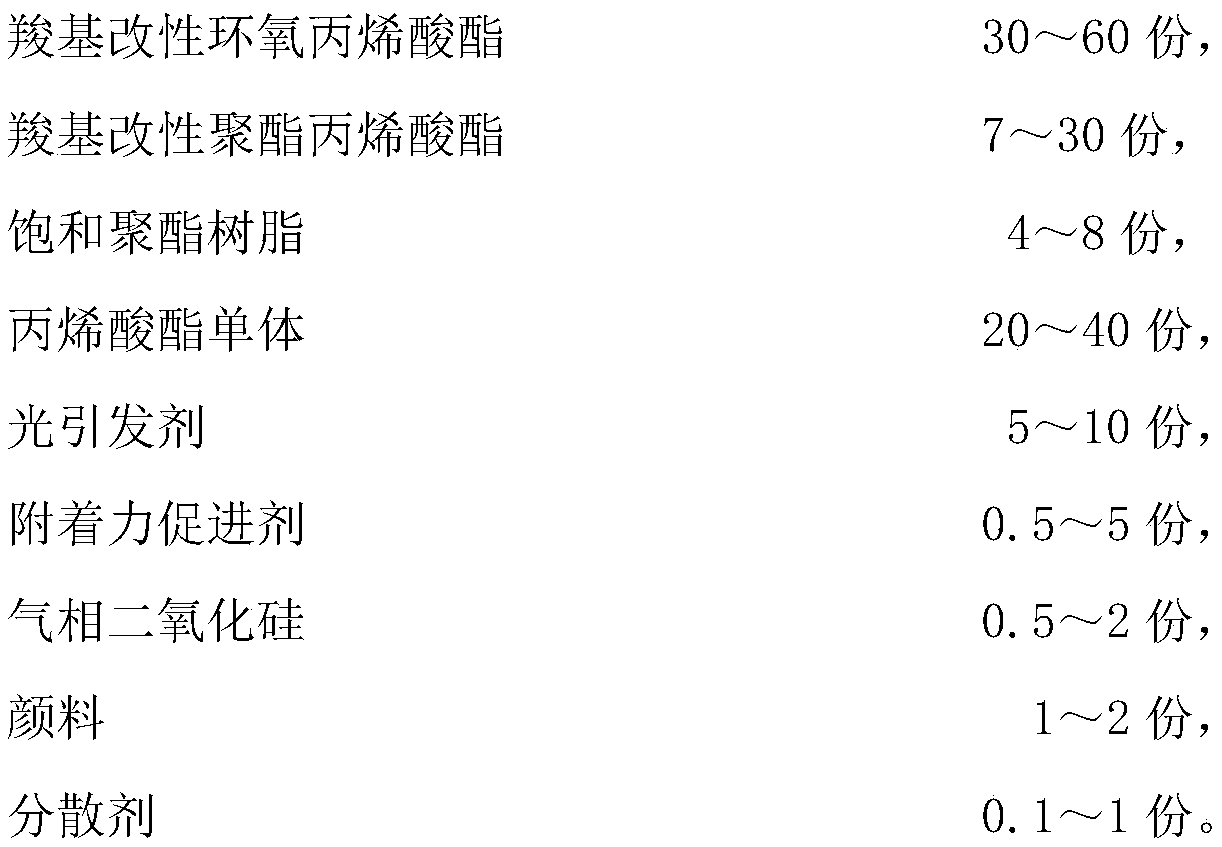

Rapid printing etching-resistant ink

The invention provides a rapid printing etching-resistant ink. The rapid printing etching-resistant ink comprises, by weight, 30-60 parts of carboxyl modified epoxy acrylate, 7-30 parts of carboxyl modified polyester acrylate, 4-8 parts of saturated polyester resin, 20-40 parts of an acrylate monomer, 5-10 parts of a photoinitiator, 0.5-5 parts of an adhesion promoter, 0.5-2 parts of fumed silica,1-2 parts of a pigment and 0.1-1 part of a dispersing agent. The anti-etching ink is high in printing speed, and has the advantages of excellent anti-sticking effect, good acid etching resistance andadjustable alkali liquor film stripping speed.

Owner:SHANGHAI WEIKAI CHEM +2

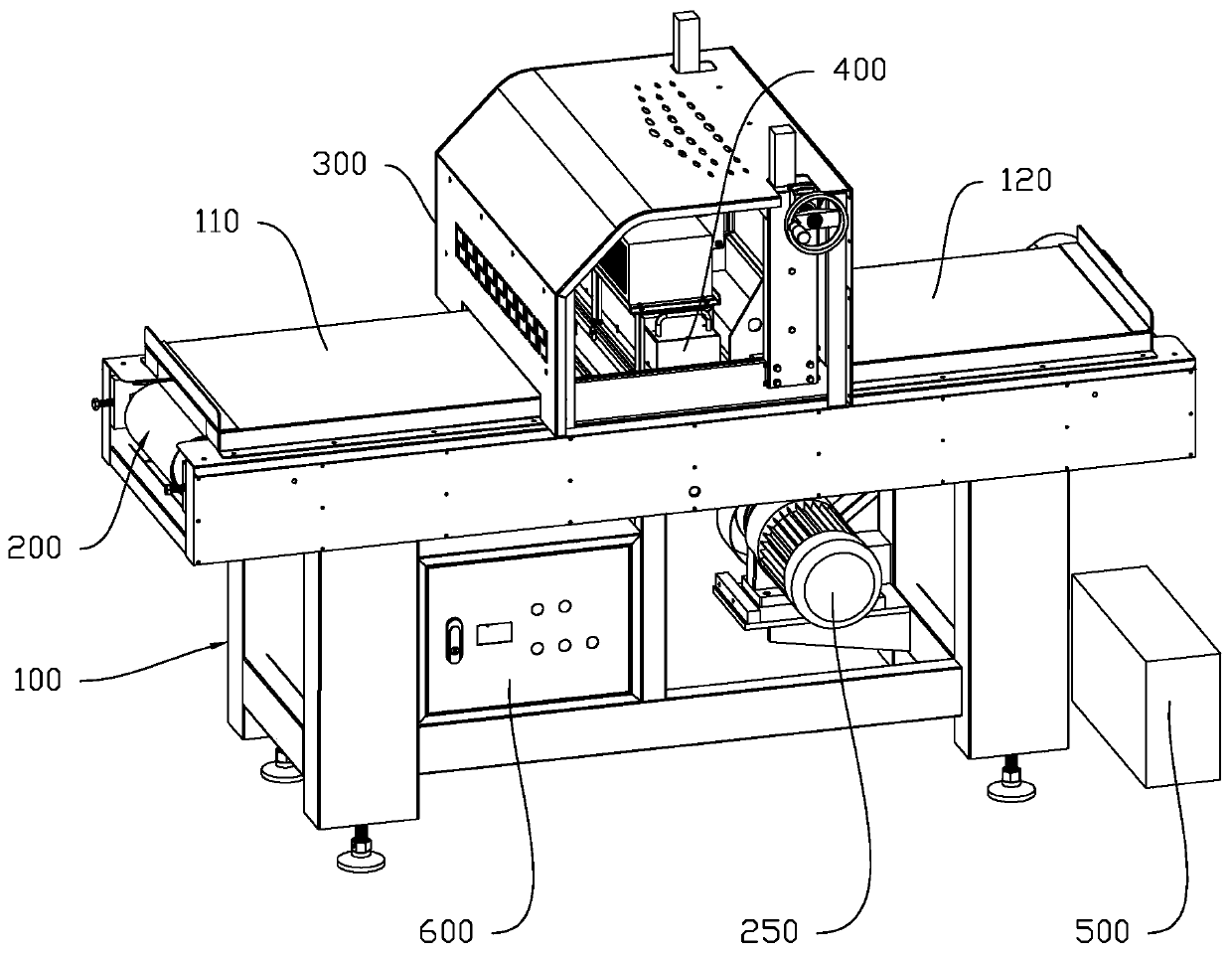

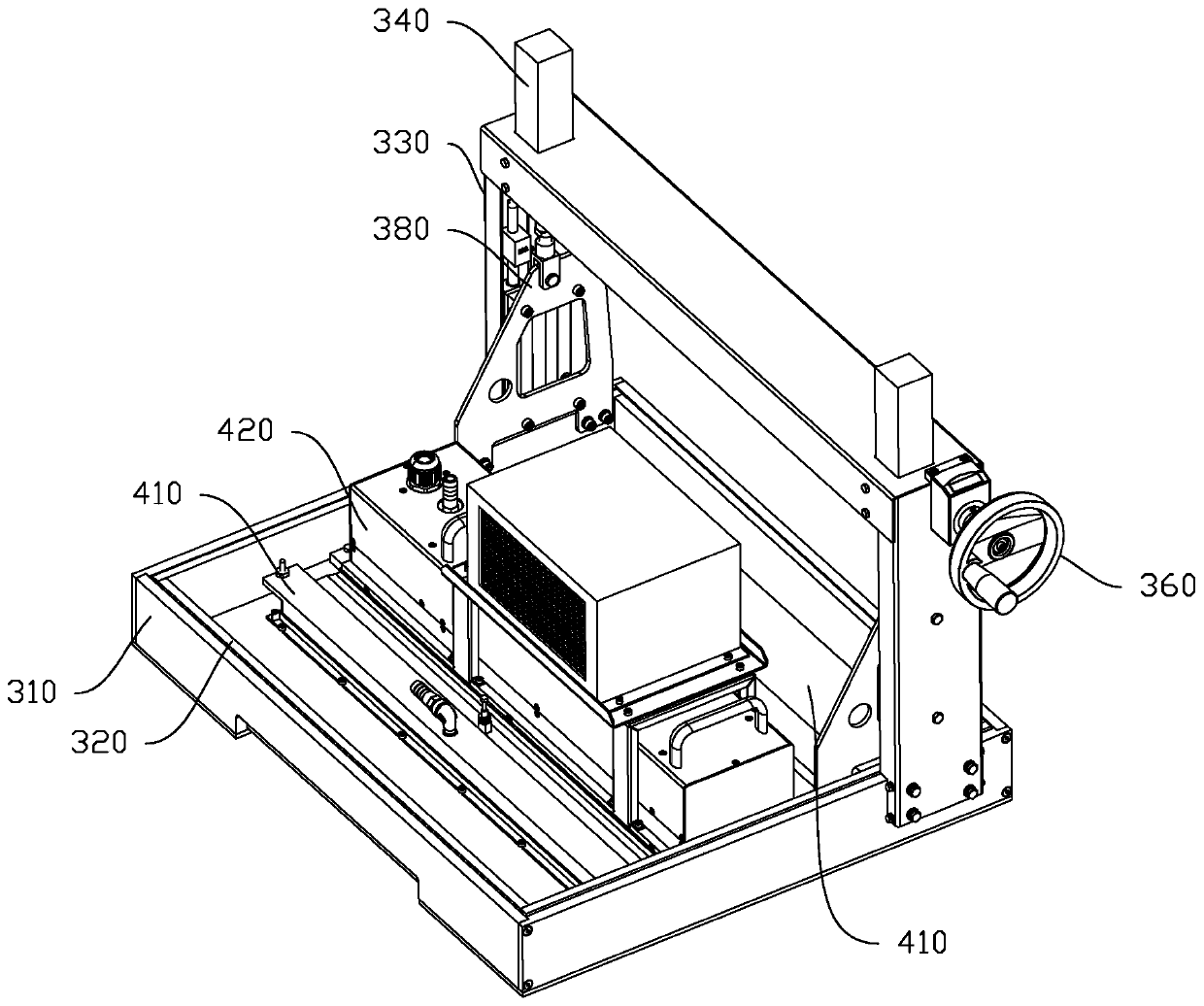

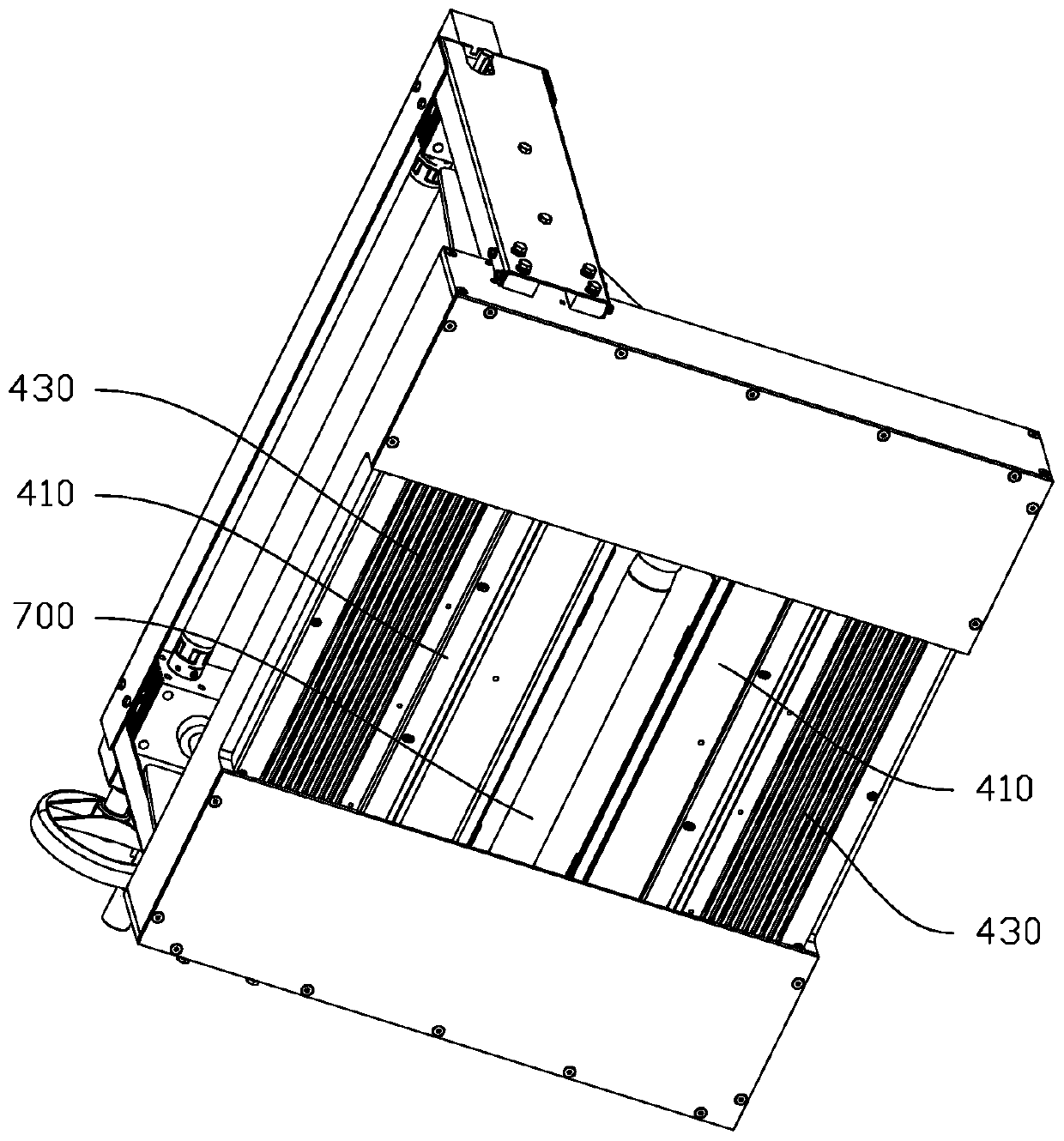

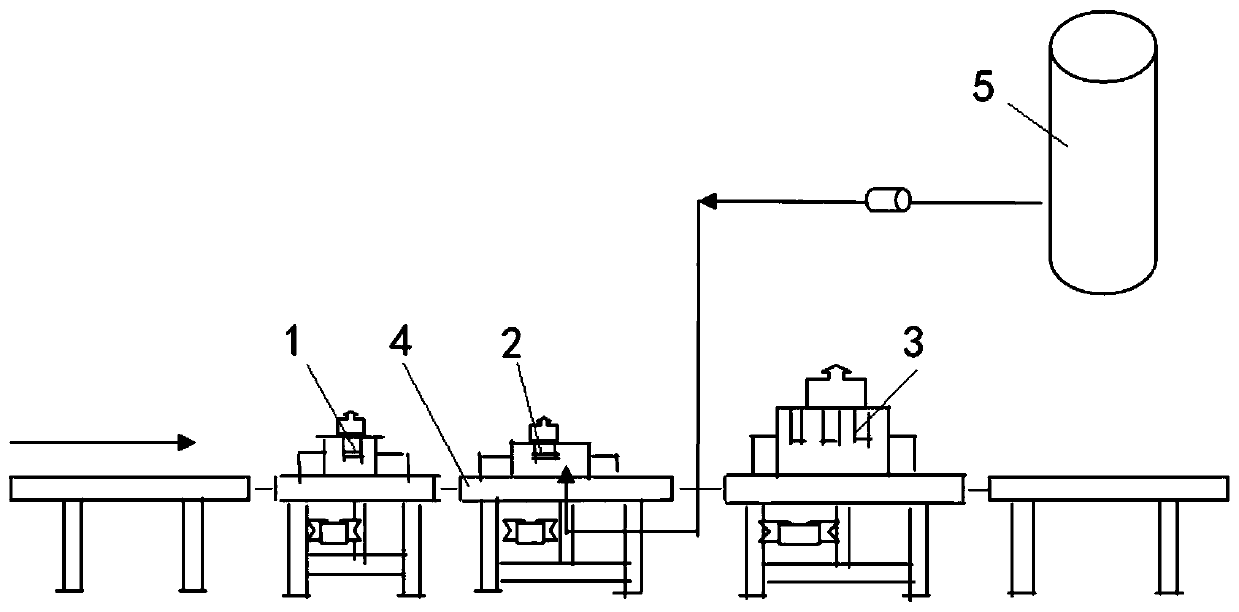

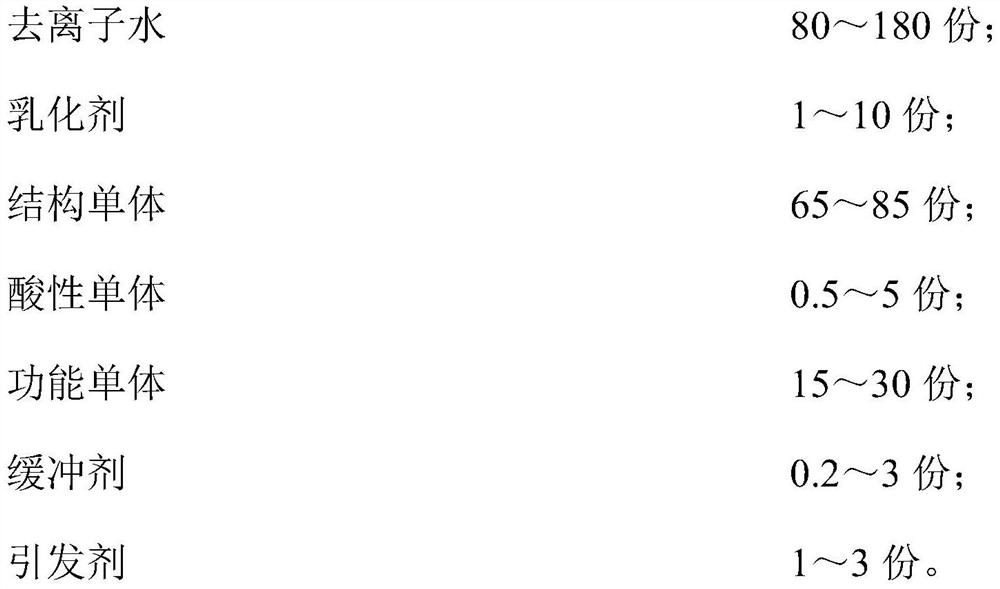

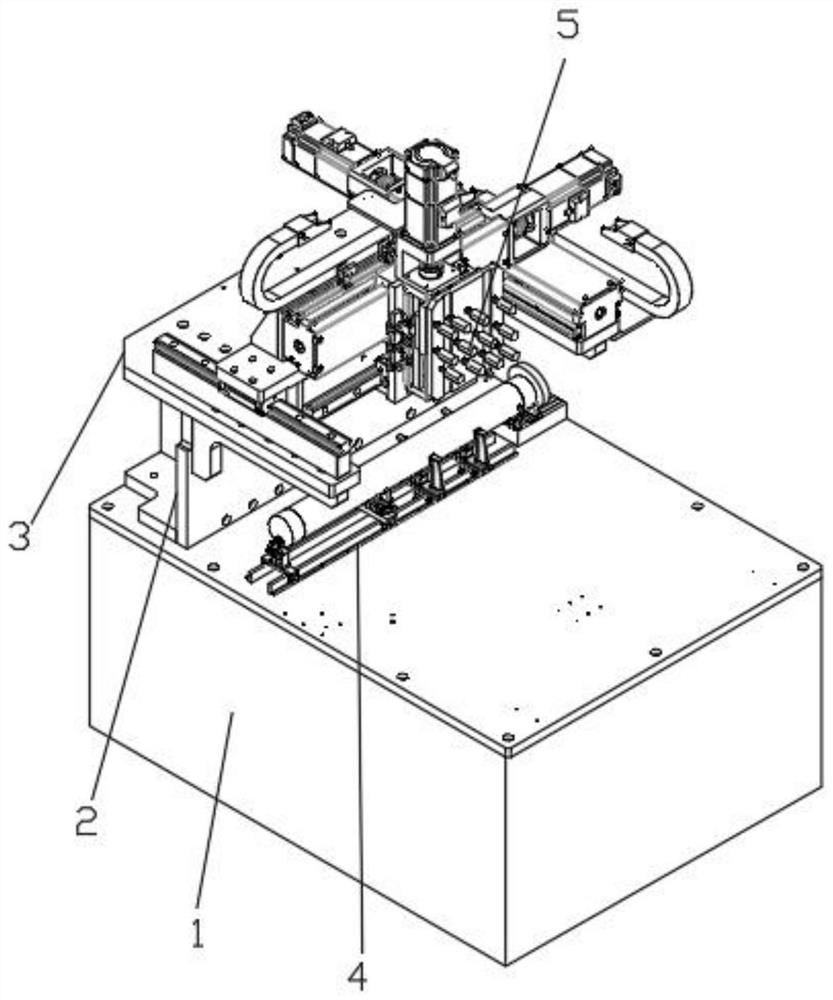

Ultra-matte light matting machine

PendingCN110787978AScratch resistantEfficient restorativePretreated surfacesCoatingsEngineeringNitrogen gas

The invention discloses an ultra-matte light matting machine which comprises a machine frame, a conveying mechanism, an air curtain spraying device and a heating pressurizer. The machine frame is provided with an air control device; the conveying mechanism is arranged in the machine frame; a matt lamp box is fixed at the top of the machine frame and located above the conveying mechanism, the mattlamp box is internally provided with a matt lamp, and the matt lamp is located at the bottom of the matt lamp box; the air curtain spraying device is arranged in the matte lamp box and located at thebottom of the matte lamp box; the heating pressurizer is arranged on the outer side of the machine frame, an outlet of the heating pressurizer is connected with the air curtain spraying device, the heating pressurizer is controlled by the air control device, plates are conveyed below the matte lamp box through the conveying mechanism, nitrogen is heated and pressurized through the heating pressurizer, the nitrogen is introduced below the matte lamp box through the air curtain spraying device to isolate oxygen, and then the matte lamp is used for breaking the surface gloss of UV paint to form an extreme matte effect of losing light. Plate surfaces reach the extreme matte effect of 0.5-5.0 brightness.

Owner:FOSHAN SHUNDE PURETE MECHANICAL CO LTD

Matt vehicle interior decoration material and preparation method thereof

The present invention discloses a matt vehicle interior decoration material and a preparation method thereof, wherein the material comprises, by mass, 25-34 parts of a PC resin, 27-42 parts of a ABS resin, 5-15 parts of glass fibers, 4-11 parts of a lubricant, 6-19 parts of polytetrafluoroethylene, 4-12 parts of polydimethylsiloxane, 3-12 parts of an antioxidant 168, and 4-10 parts of an antioxidant 1010. The prepared interior decoration material of the present invention has characteristics of matt effect, no requirement of secondary processing, production cost reducing, and environmental pollution preventing.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

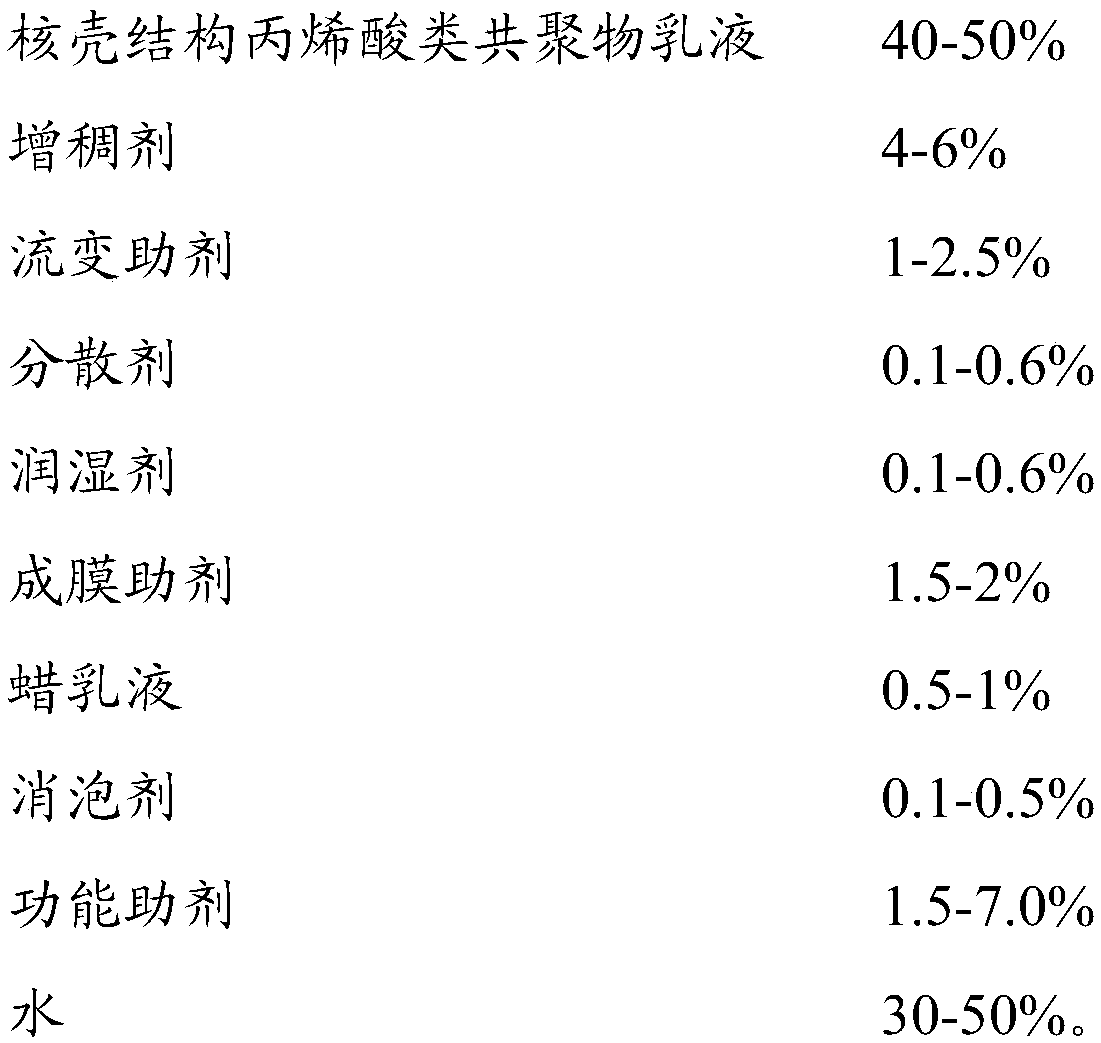

Non-thickening ultraviolet curing coating material and preparation method thereof

The invention discloses a non-thickening ultraviolet curing coating material and a preparation method thereof. The coating material comprises the following components in parts by weight: a filler comprising transparent spherical micro-powder and fumed silica micro-powder, and functional aids comprising a dispersing agent, an antifoaming agent, a leveling agent, a photo-initiation aid and a photo-initiator. According to the invention, a diluent is used for reducing the viscosity of a coating material, so that the coating material can be leveled, the cross-linking speed of hydroxyl acrylic resinand polyurethane acrylate is low, and reworking is easy; hydrogen bonds are formed between the diluent and the surface of a coated object, so that the adhesive force is improved, paint removal is prevented, and the structure of double bonds, ester groups and alkane in molecules enables a paint film to have good elongation at break; the dispersing agent disperses the polyurethane acrylate, so thatthe coating material is not easy to thicken; and the filler enhances the roughness of the paint film, lowers the glossiness to achieve the matte effect, and solves the problems in the existing coating material.

Owner:中山市鑫峰光固化材料有限公司

Matte gloss clear finish paint and preparation method thereof

Owner:广东嘉宝莉科技材料有限公司

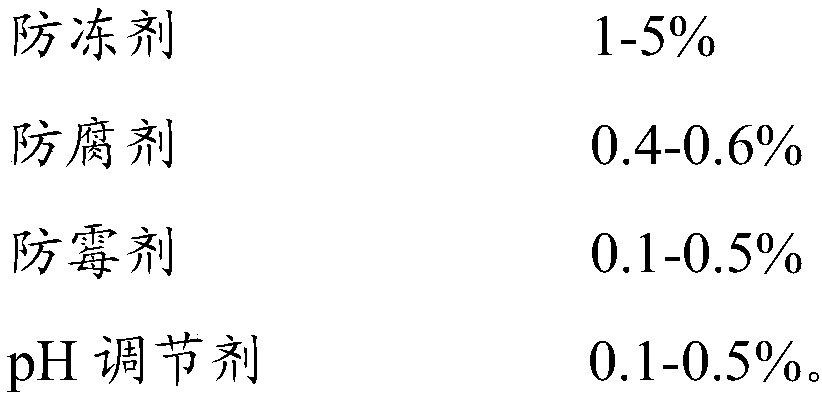

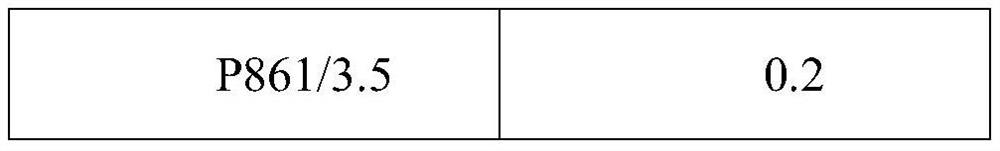

Matte water-in-water base paint, preparation method and matte water-in-water paint

The invention relates to a matte water-in-water base paint and a preparation method thereof, which is prepared from the following components by weight: 30-50 parts of deionized water, 0.2-0.3 parts of a dispersant, and 0.2-0.3 parts of a defoaming agent 0.5 parts, 1.0-2.0 parts of antifreeze, 1.0-2.0 parts of film-forming aids, 1-5 parts of expanded vitrified microbeads, 1-5 parts of titanium dioxide, 1-8 parts of kaolin, 0.8-2.0 parts of cellulose, pH 1.0-2.0 parts of conditioner, 30-50 parts of emulsion, 0.1-0.5 parts of preservative, 5-10 parts of 10wt% protective colloid solution and 0.1-0.5 parts of thickener; can reduce the gloss of water-in-water base paint, reach Matte effect; the matte water-in-water paint formulated with the matte water-in-water base paint is also provided, and the mass ratio is (3‑5): (2‑4): (3‑5) The matte water-in-water base paint, granulation liquid and continuous phase are prepared; the overall gloss of the matte water-in-water paint of the present invention is low, so that when it is sprayed on the real stone paint, there will be no bright spots and blooming phenomenon, and the imitation stone The effect is realistic and natural.

Owner:河北莱恩斯新材料科技有限公司

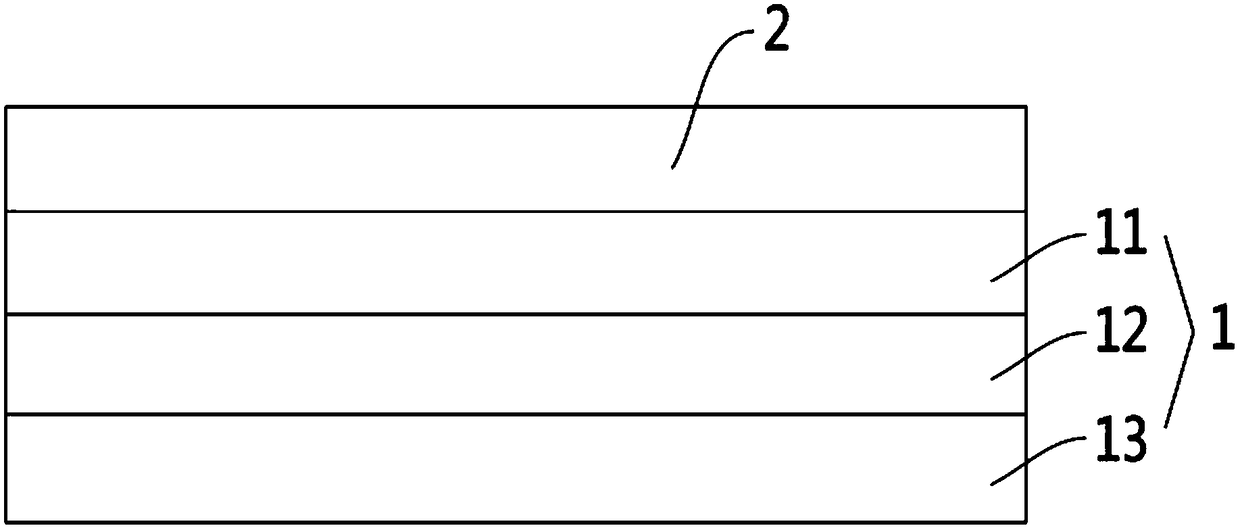

Matte BOPP aluminum laminated film for labels and production technology thereof

PendingCN109228594AEliminate coating processLow costSynthetic resin layered productsCoatingsSolventNano silicon dioxide

The invention discloses a matte BOPP aluminum laminated film for labels. The matte BOPP aluminum laminated film comprises a matte BOPP base film and an aluminum layer plated on the upper surface of the matte BOPP base film, wherein the matte BOPP base film comprises a corona layer, a middle layer and a heat-seal layer in turn from top to bottom. A production technology for the matte BOPP aluminumlaminated film for labels comprises the following steps: 1) firstly, adopting an extruder for extruding the matte BOPP base film; 2) preparing the matte BOPP base film in the manner of two-way stretching; 3) lastly, performing vacuum aluminizing on the upper surface of the matte BOPP aluminum laminated film at vacuum degree of above 10-4mbar. In the process of extrusion molding, a matte master batch is used and HDPE and nano-silica anti-blocking agent are added for directly molding a film with a matte effect, and no matte layer is coated, so that the coating process is avoided, the cost is saved and the influence of solvent coating on environment is reduced.

Owner:嘉兴鹏翔包装材料有限公司

A kind of silicon-modified matte UV resin and preparation method thereof

ActiveCN110358414BNot easy to change colorAvoid crackingEpoxy resin coatingsOrganic acidPolymer science

Owner:JIANGMEN HENGZHIGUANG ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

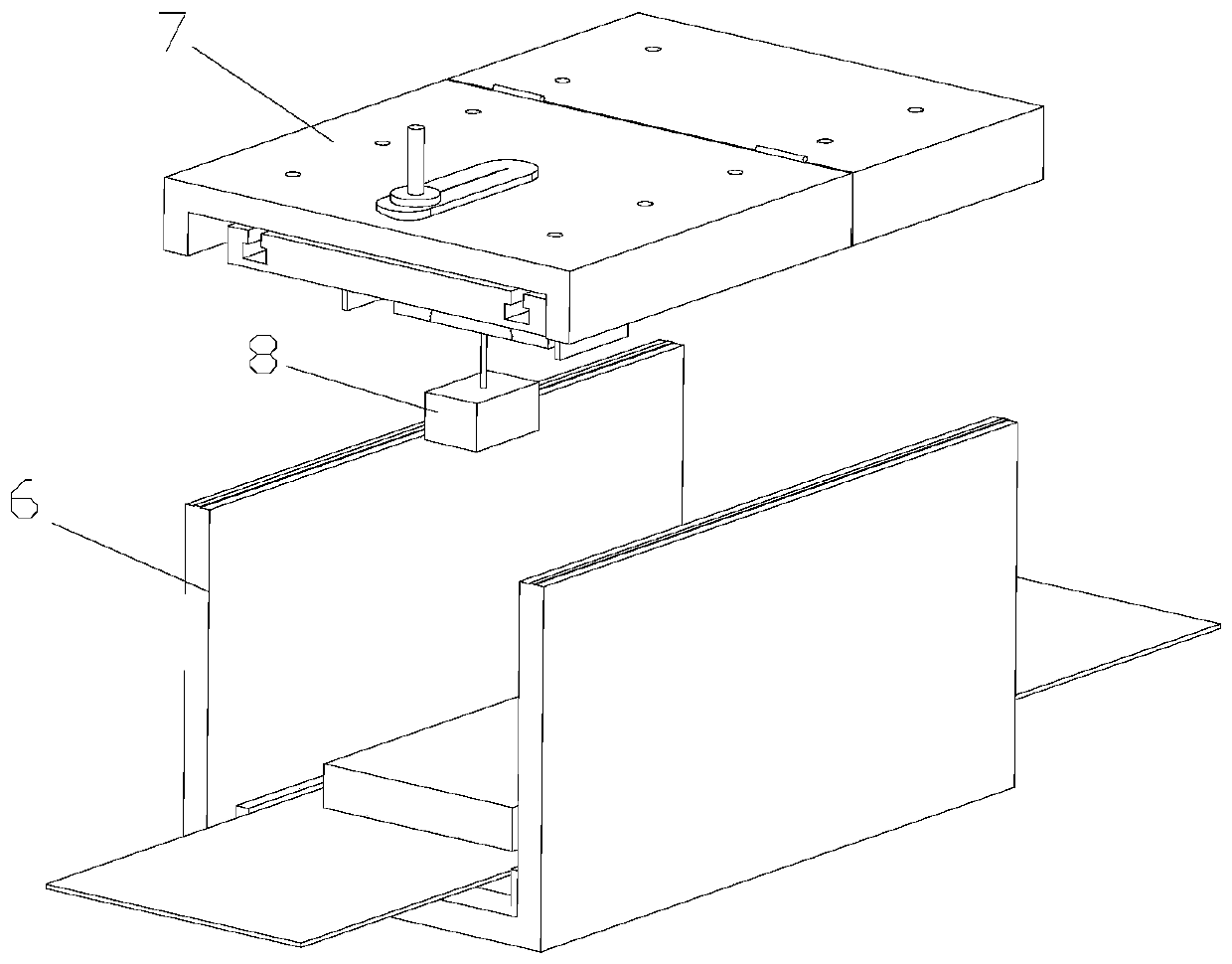

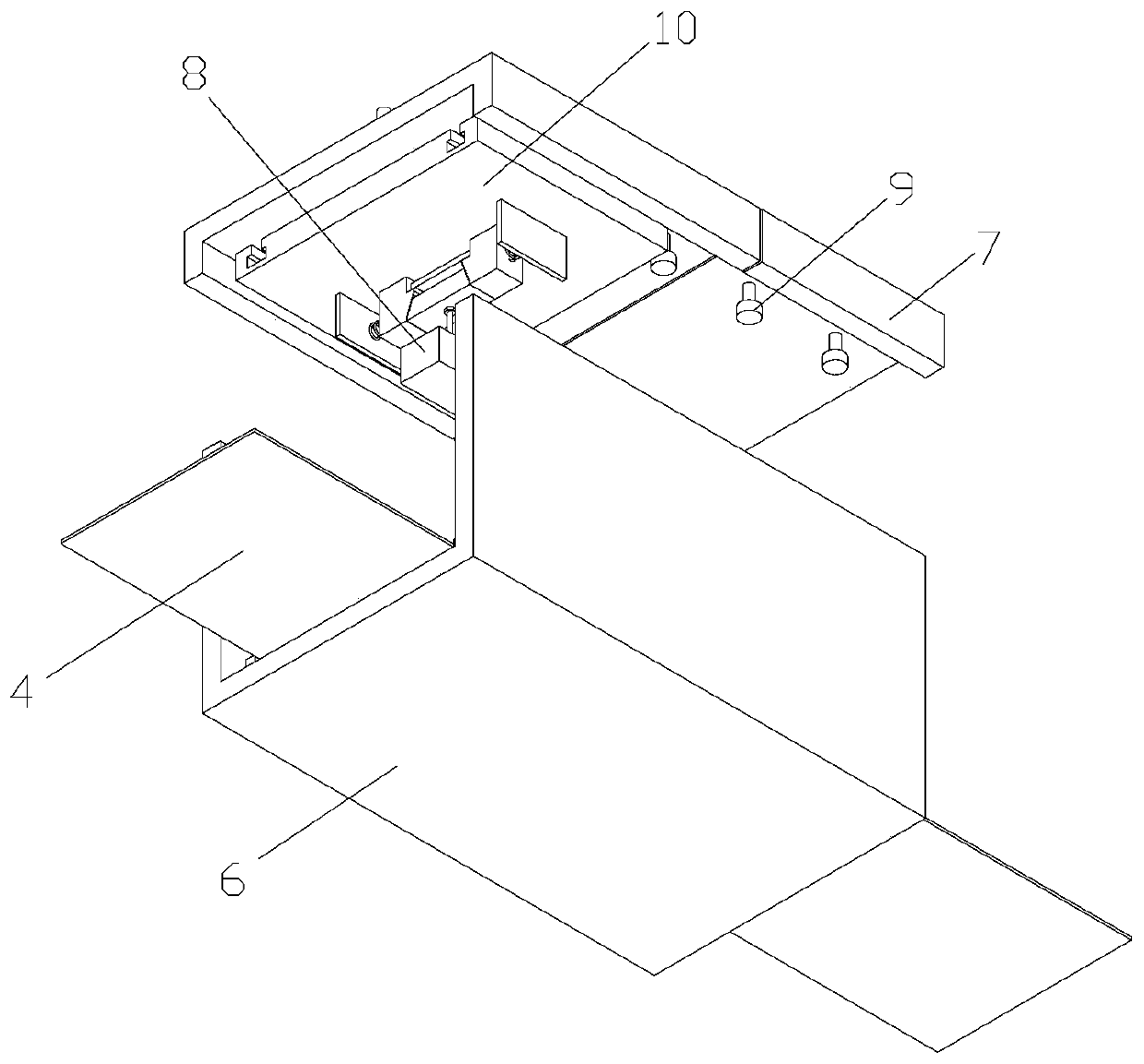

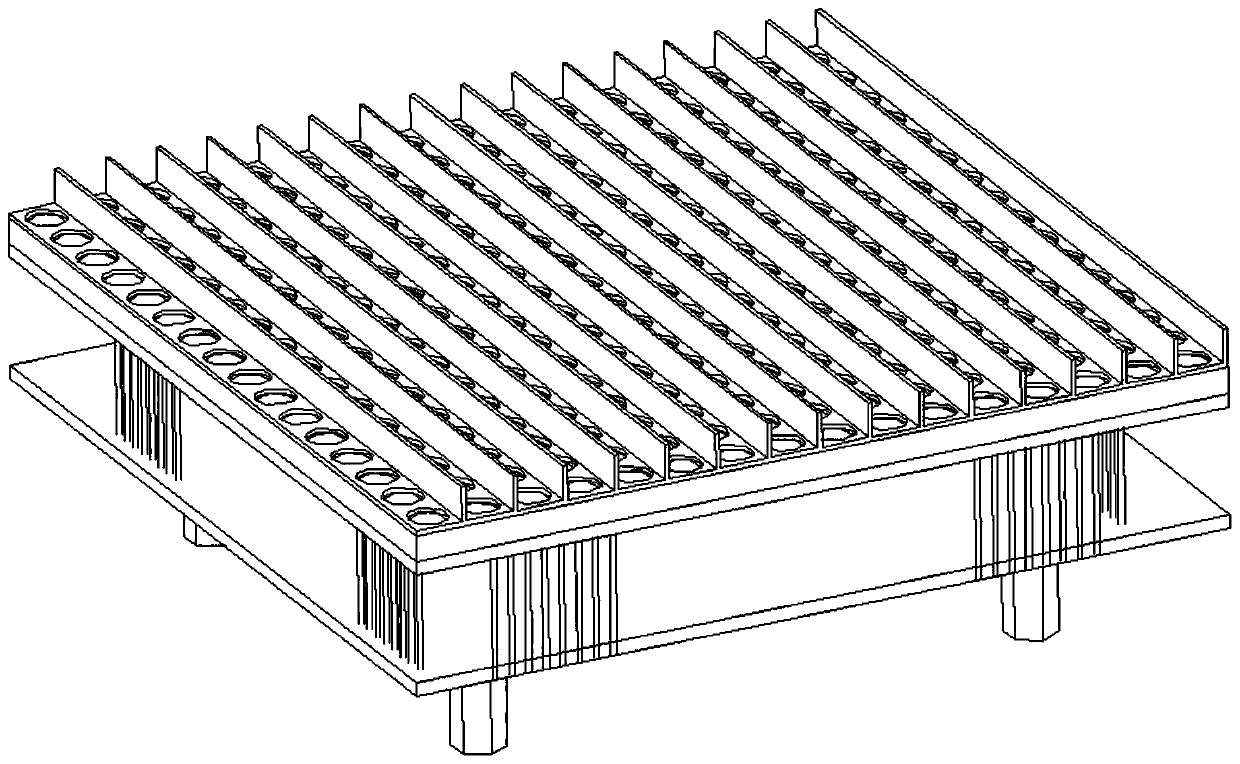

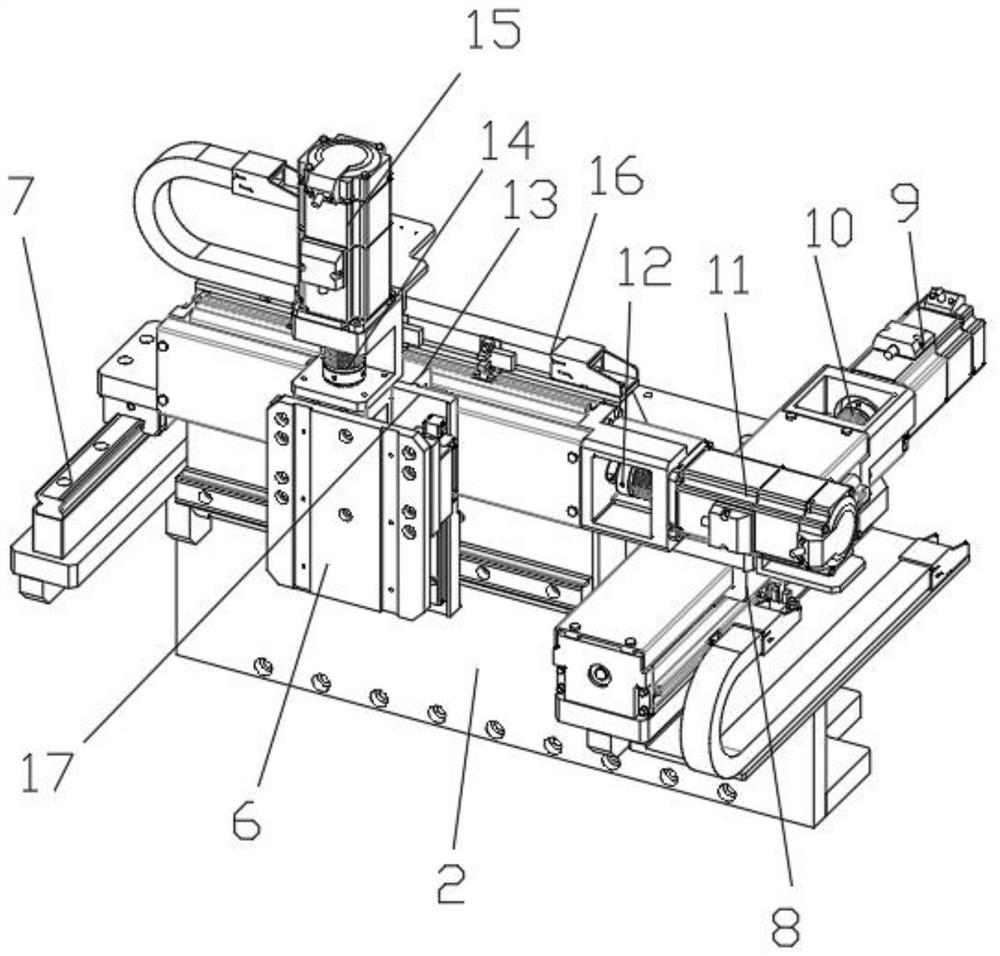

A device for making ultra-dumb skin-feeling boards with lamps

ActiveCN110976247BOvercomes the inability to achieve an ultra-matte skin feelAchieve a matte finishPretreated surfacesCoatingsCoated surfaceLiquid state

The invention belongs to the technical field of photocuring, and particularly relates to a device for lamp manufacturing of a super-matte skin feeling plate. The device comprises a gallium lamp box, an xenon lamp box and a mercury lamp box which are arranged in sequence in the conveying direction of the plate, a conveying belt used for conveying the plate is arranged among the three lamp boxes, meanwhile, a seal space used for containing the plate which is conveyed in place through the conveying belt is further included, an oxygen displacement device is arranged in the xenon lamp box, and ultraviolent light with the wavelength being 172 nm is generated in the oxygen displacement device. A 172 nm quasimolecule xenon lamp is adopted for radiating a UV coating, due to the limited penetratingcapacity of the ultraviolet light at the wave segment, a coating with the thickness about 0.1 micrometer on the surface of the coating is subjected to photocuring, the coating with the larger thickness is still in a liquid state, therefore, the photocured surface layer coating can generate uniform wrinkles due to the shrinkage reason, the microcosmic concave and convex surface can be generated, the matte skin feeling effect is achieved, the defect that extinction powder cannot achieve the super-matte skin feeling is overcome, and extinction powder is not needed.

Owner:CHANGZHOU WEIXING DECORATIVE MATERIALS +1

Preparation method of water-based matte coating

In order to solve the problems that when a matte layer is coated on an aluminum-plastic composite film, the aluminum-plastic composite film has a gray feeling and is not uniform in coating, the invention provides a preparation method of a water-based matte coating. A mixed solution of water, acrylic acid and silicon dioxide is coated on a surface layer, needing matte treatment, of the aluminum-plastic composite film, so that the aluminum-plastic film achieves a matte effect. The method is easy to operate, convenient to manufacture, firm in aluminum plastic film coating and safe and reliable in packaging, and gives people an elegant feeling.

Owner:SUZHOU RDX NEW MATERIAL TECH CO LTD

A weather-resistant matte pc/asa alloy material

ActiveCN109337327BHas the performance of weather resistance and high cold resistanceGood physical propertiesAcrylonitrilePolycarbonate

The invention discloses a weather-resistant matte PC / ASA alloy material, which comprises the following components in parts by weight: 69-75 parts of bisphenol A polycarbonate resin, acrylate rubber-acrylonitrile-styrene bonded Branch copolymer 14-20 parts, silicone toughening agent 3-7 parts, compatibilizer 2-4 parts, matting agent 4 parts, hindered phenolic antioxidant 0.2 part, auxiliary antioxidant 0.2 part, ultraviolet absorber 0.3 parts and lubricant 0.2 parts. The alloy material is made of bisphenol A polycarbonate, acrylic rubber, acrylonitrile and styrene graft copolymer as the main raw materials, supplemented by silicone compatible toughening, organic matting agent, high-efficiency antioxidant and special UV Absorbent and other components are combined, and the synergy of each component is used to achieve a matte matte effect on the surface of the material; the alloy material has the performance of weather resistance and high cold resistance, and has excellent physical properties, which can meet the requirements of outdoor weather resistance and can be widely used Used in automotive interior and exterior decoration, office equipment, communication equipment and outdoor lighting components.

Owner:南京运昶高分子材料有限公司

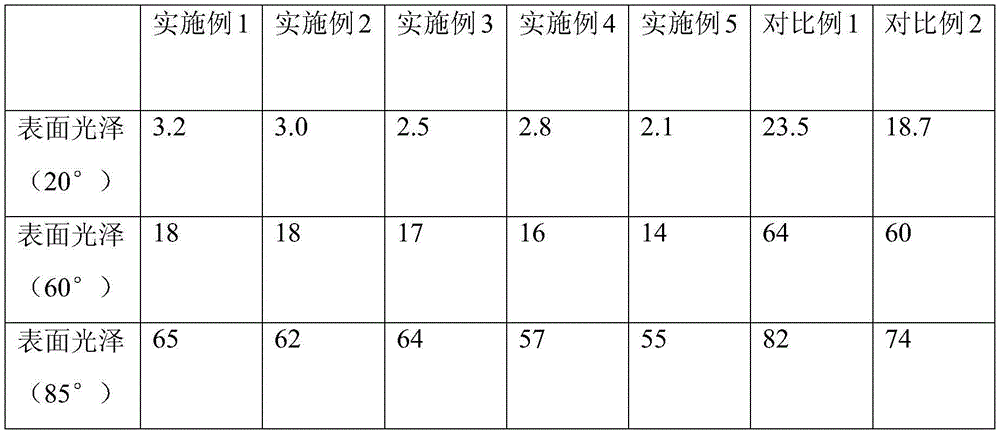

A kind of water-based two-component polyurethane matte coating and its preparation method and application

ActiveCN113088174BHas a matte finishGloss ControlPolyurea/polyurethane coatingsPolymer scienceEmulsion

The invention provides a water-based two-component polyurethane matte coating and its preparation method and application. The water-based two-component polyurethane matte coating includes A component and B component, and the preparation raw materials of the A component include the following weight Components in parts: 60-90 parts of hydroxyacrylate emulsion; 5-20 parts of deionized water; 0-30 parts of powder; 0.5-2.5 parts of wetting and dispersing agent; 0.2-2 parts of thickener; defoamer 0.2 to 1 part; 0.5 to 1.5 parts of preservative; 0.2 to 2 parts of film-forming aid; the raw materials of component B include the following components in parts by weight: 0.1 to 5 parts of Covestro 307 water-based curing agent. The polyurethane matte paint of the invention can have a matte effect without adding additional matting powder, can greatly improve the water resistance, permeability and stability of the paint, and is suitable for the field of paint.

Owner:DONGGUAN CTL NEW MATERIAL TECH

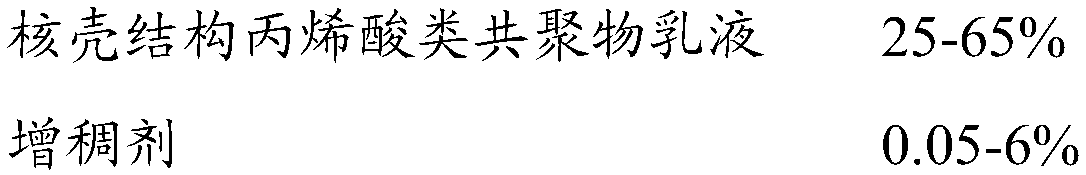

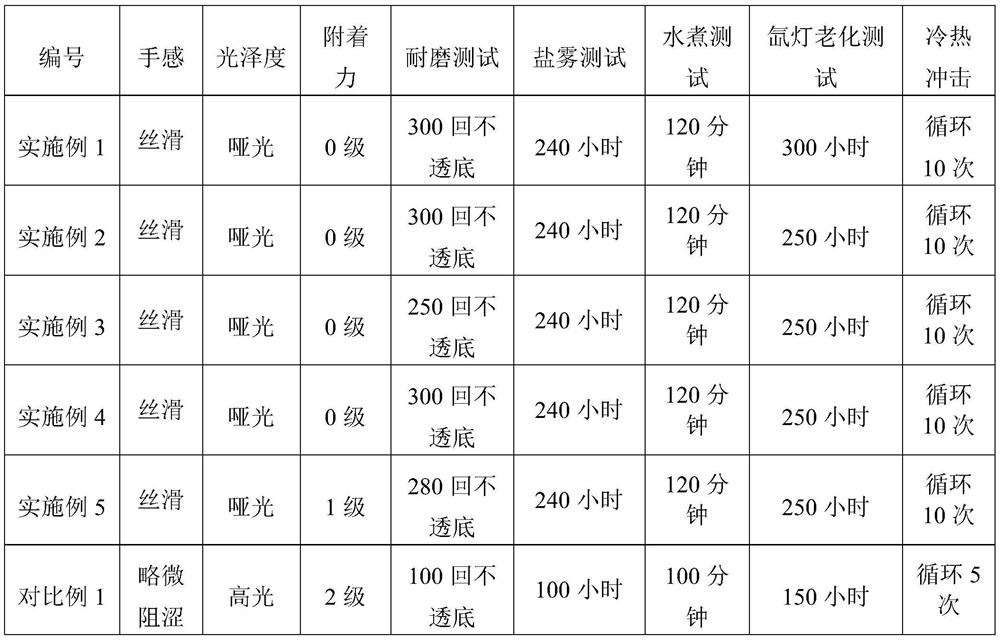

Two-component polyurethane self-extinction velvet-feeling top-coat paint and preparation method thereof

InactiveCN113136135AAchieve a matte finishSpecial fluffy touchPolyurea/polyurethane coatingsPolymer scienceEmulsion

The invention discloses a two-component polyurethane self-extinction velvet-feeling top-coat paint and a preparation method thereof. A top-coat formula component A is prepared from the following components in parts by mass: 0-3% of water; 95 to 98% of emulsion; 0.8%-1.2% of a thickening agent; 1-1.5% of a leveling agent; and 0.15%-0.2% of a defoaming agent. And the component B is composed of the following components in parts by mass: 100% of a curing agent. Wherein the component A and the component B are mixed by adding water, and the mixing ratio of parts by mass is as follows; the ratio of the component A to the component B to the water is 100: 5: 10. According to the formula of the components, the prepared finish paint film is rough and soft in surface, diffuse reflection extinction is formed, the matte effect is achieved, and meanwhile, the finish paint has a special fluff touch sense, is very comfortable to touch and is very suitable for an inner wall finish. No preservative and mildew inhibitor is added, the VOC is low, and the paint is more environment-friendly and healthier.

Owner:广东金涂宝新材料股份有限公司

A treatment-free matte varnish ink for pet film gravure printing

ActiveCN104861775BImprove aestheticsAchieve freedom of controlInksWaxPolyethylene terephthalate glycol

Owner:DONGCHANG IND LINHAI CO LTD

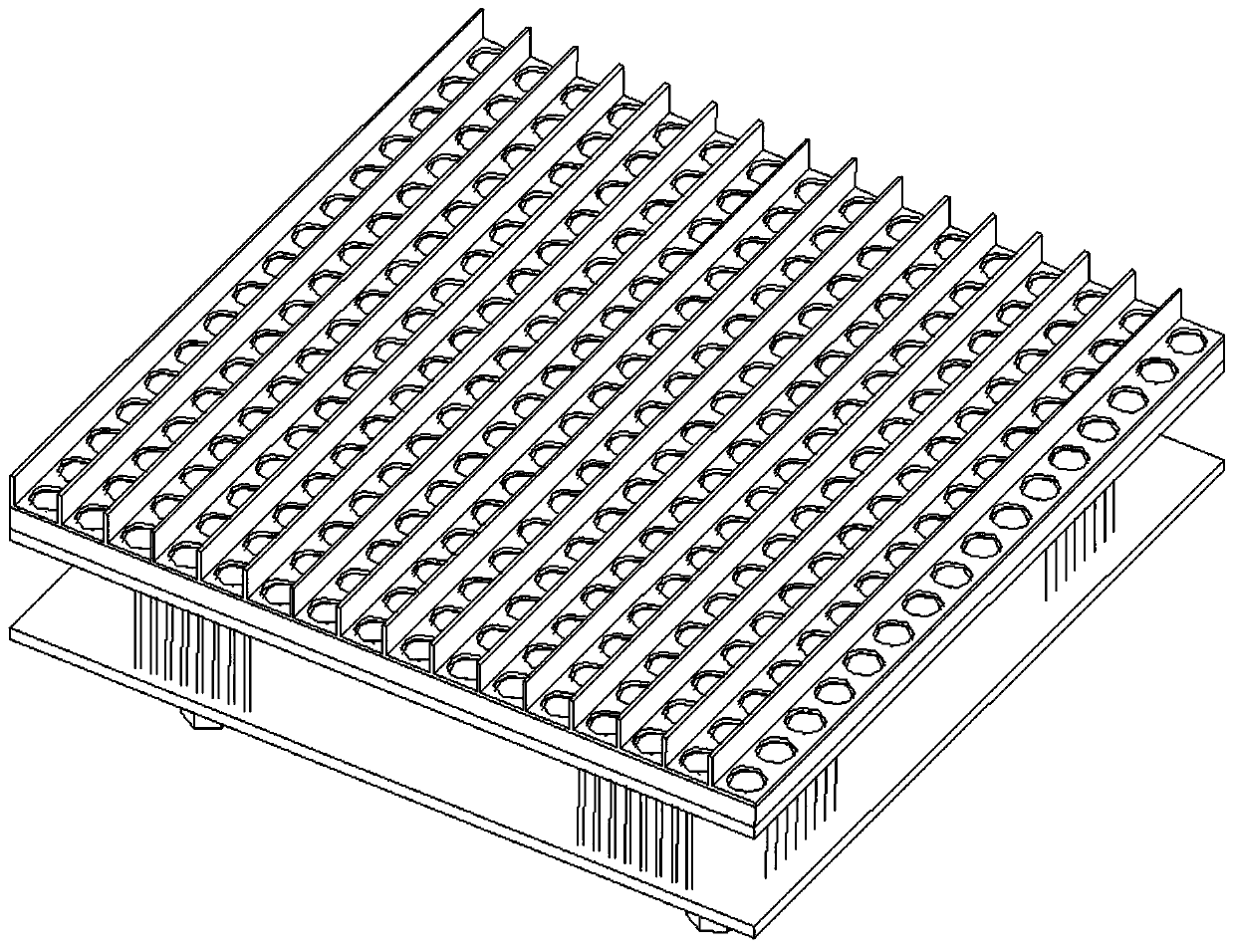

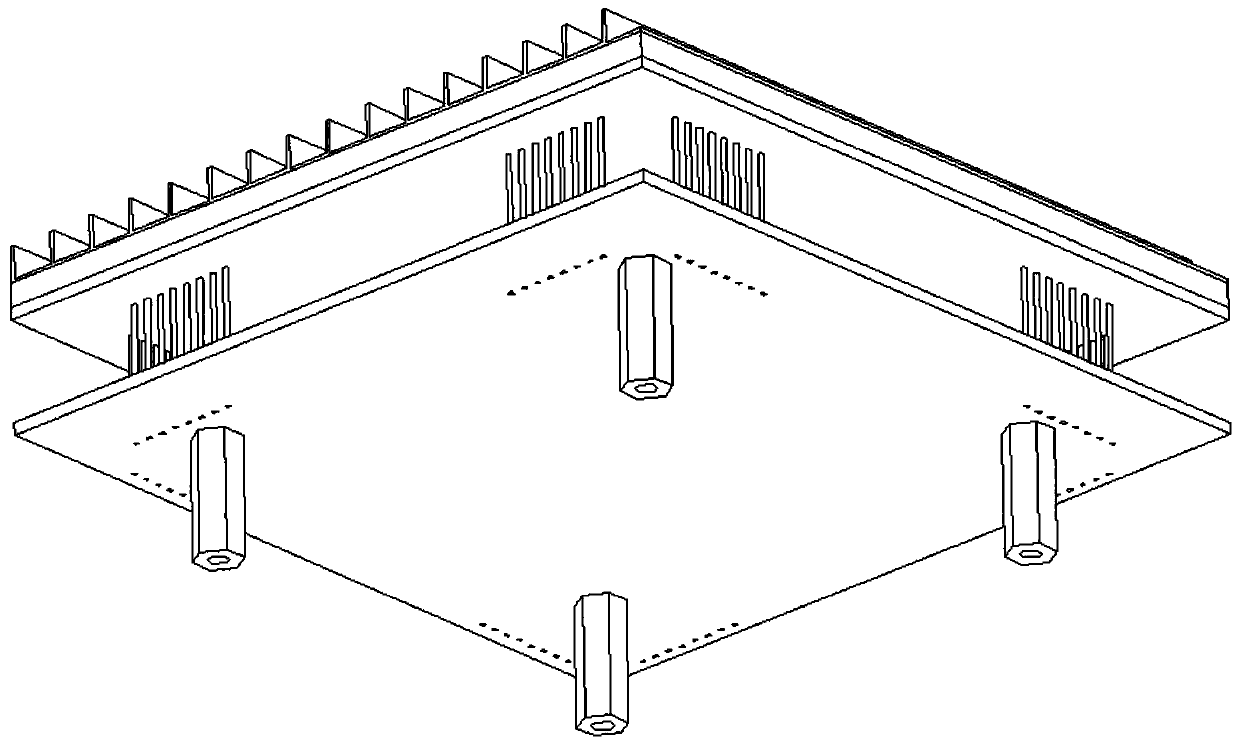

LED display screen with visual angle

InactiveCN111105726ASpread evenlyAchieve consistencyIdentification meansLED displayLight-emitting diode

The invention discloses an LED display screen with a visual angle. The LED display screen comprises a first PCB panel and a second PCB panel, hneycomb hole ceramic chips are uniformly and fixedly connected to the top surface of the second PCB panel at equal intervals; light emitting diodes are fixedly connected to the top of the second PCB panel and located in gaps between the honeycomb hole ceramic pieces, diffusion agent colloid is used for filling in a gap position between the honeycomb hole ceramic chips and above the light emitting diode; and the top of the honeycomb hole ceramic piece isfixedly connected with a honeycomb hole aluminum sheet, pins are evenly arranged on the two sides of the top of the second PCB panel, and the bottoms of the pins penetrate through and extend to the position below the first PCB panel. According to the LED display screen with the visual angle, the consistency of the colloid surface of an LED device is achieved, the 120-degree visual effect is achieved, the process is simple, and the cost is low.

Owner:深圳市生辉煌电子有限公司

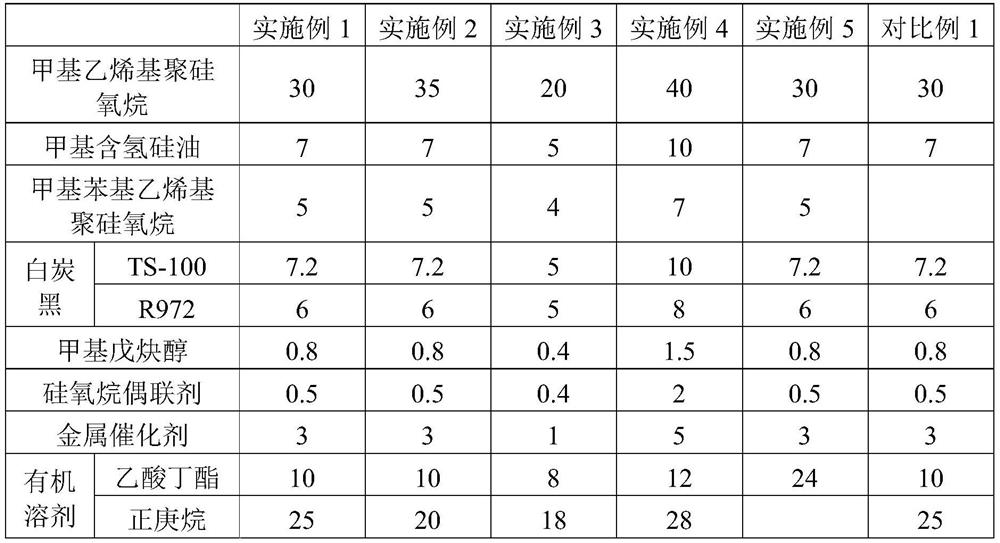

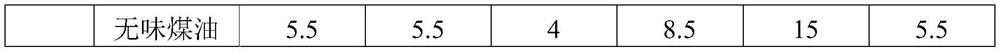

A coating for zero-degree silica gel and preparation method thereof

The invention discloses a coating for zero-degree silica gel and a preparation method thereof, and the coating for the zero-degree silica gel comprises the following components in parts by weight: 20-40 parts of methyl vinyl polysiloxane, 5-10 parts of methyl hydrogen-containing silicone oil, 3-7 parts by weight of methyl phenyl vinyl polysiloxane, 0.2-2 parts of an inhibitor, 0.2-2 parts of a siloxane coupling agent, 8-20 parts of white carbon black, 30-50 parts of an organic solvent and 1-5 parts by weight of a metal catalyst. When the coating is applied to the surface of a zero-degree silica gel product, the matte effect and the silky hand feeling can be realized, and the coating has excellent adhesive force, heat resistance, water resistance, corrosion resistance, friction resistance and UV aging resistance.

Owner:HUNAN SOKAN NEW MATERIAL

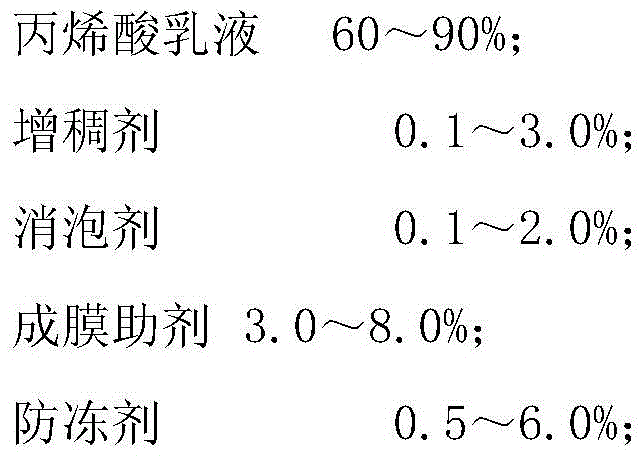

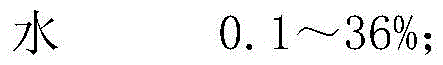

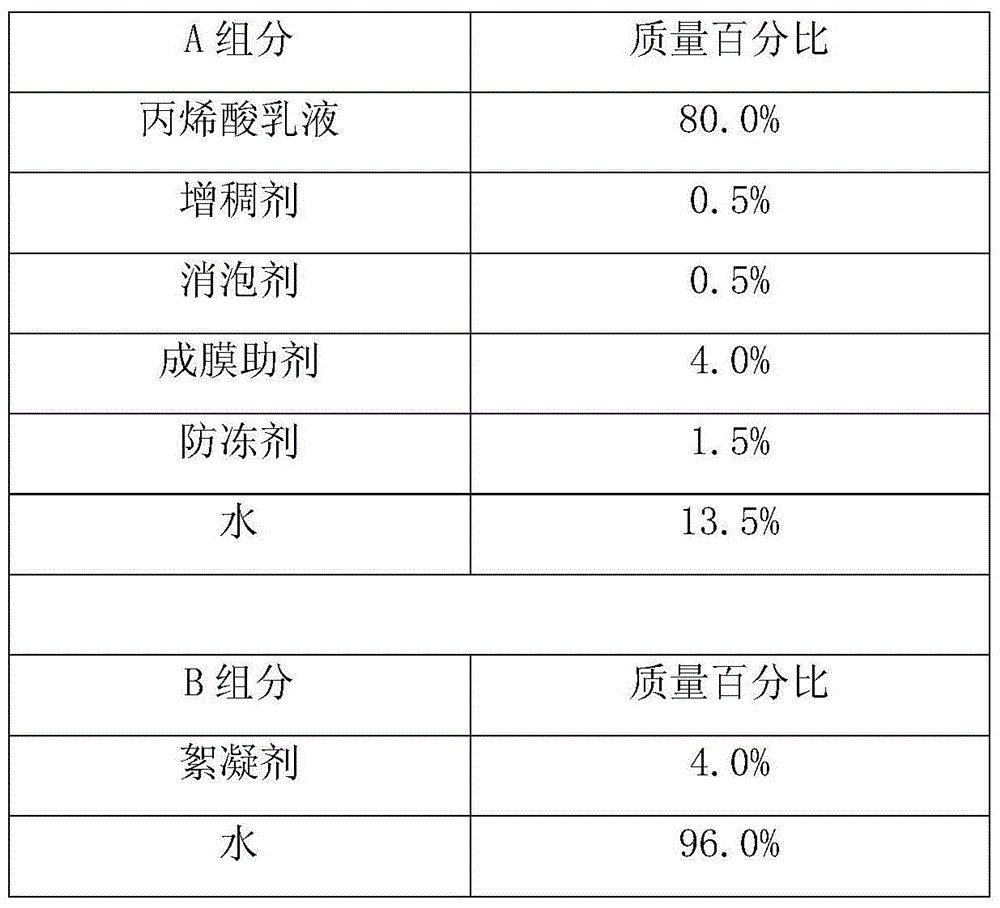

Two-component water-based matte finish varnish and preparation method thereof

The invention discloses double-component water-based matte coating varnish and a preparation method thereof. The varnish comprises a component A and a component B, wherein the component A consists of the following components in percentage by mass: 60-90% of acrylic emulsion, 0.1-3.0% of a thickening agent, 0.1-2.0% of a defoaming agent, 3.0-8.0% of a coalescing agent, 0.5-6.0% of an antifreezing agent and 0.1-36% of water; and the component B consists of the following components in percentage by mass: 0.1-10.0% of a flocculating agent and 90.0-99.9% of water. According to the varnish, the component B contains the flocculating agent, so that the varnish film flatness is reduced and the glossiness is reduced as flocculation can be generated in an emulsion film-forming process of spraying the components A and B, the matte effect can be realized by not adding matting powder, and adverse effects caused by adding the matting powder are avoided; and especially, the component B containing the flocculating agent is separated from the component A containing the emulsion, the component B and the component A are simultaneously sprayed during use, so that a problem that the product storage stability is reduced when the component A and the component B are mixed is avoided.

Owner:FIRST NEW MATERIAL TECH DEV

A kind of UV-curable coating without thickening and preparation method thereof

ActiveCN112457764BLow viscosityImprove the level ofPolyurea/polyurethane coatingsAlkanePolymer science

Owner:中山市鑫峰光固化材料有限公司

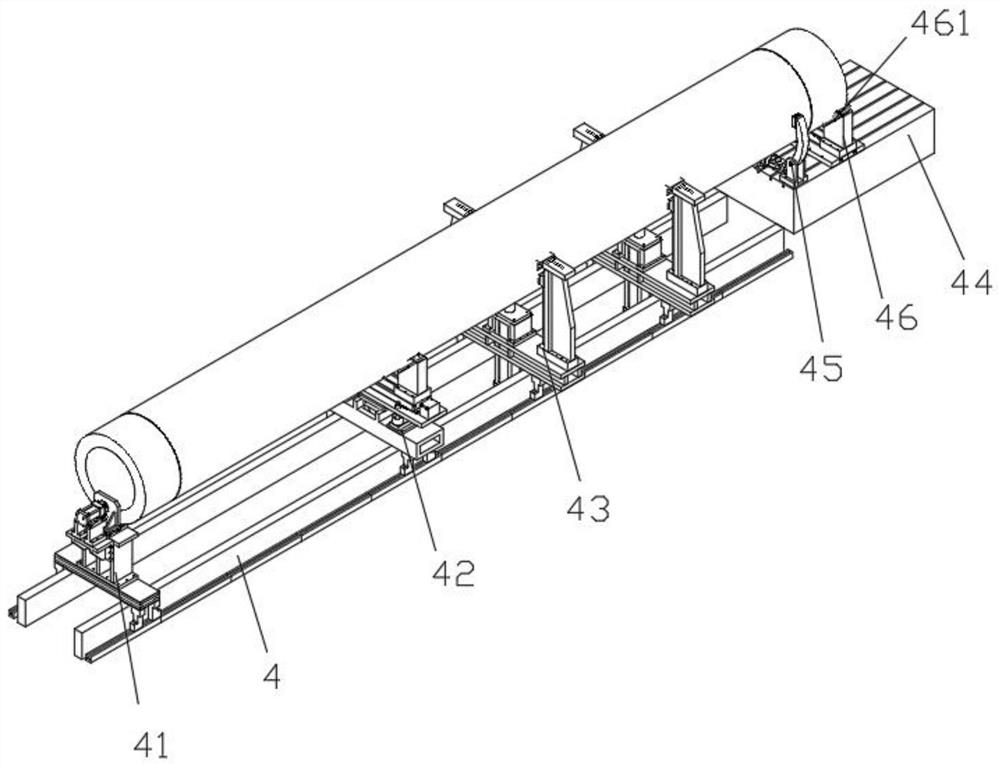

Semi-automatic sandblasting device

ActiveCN110977790BEasy to moveEasy to useBlast gunsAbrasive machine appurtenancesSand blastingElectric machine

The invention discloses a semi-automatic sand blasting device. The device comprises an operation table, a vertical plate, a transverse plate, mounting strips and sand blasting guns, wherein the vertical plate is fixedly mounted on the top of the operation table, the transverse plate is fixedly mounted on the top of the vertical plate, a first servo motor is fixedly mounted at one end of the top ofthe transverse plate, an output shaft of the first servo motor is connected with a first screw rod through a coupling, and the first screw rod is connected with a second servo motor through a first sliding block. Through the arrangement of a groove, a first cylinder and clamping plates, a tank body is fixed, and thus the inconvenience caused by manual fixing of the tank body is avoided; meanwhile, it is convenient for a rotating motor to drive the tank body to rotate, the sand blasting is more uniform, the sand blasting effect is better, tank bodies with different sizes are convenient to fix,and use is convenient; and through the arrangement of a push plate and a second cylinder, the inconvenience of the operation of manually pushing the tank body to move is avoided.

Owner:安徽元通水处理设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com