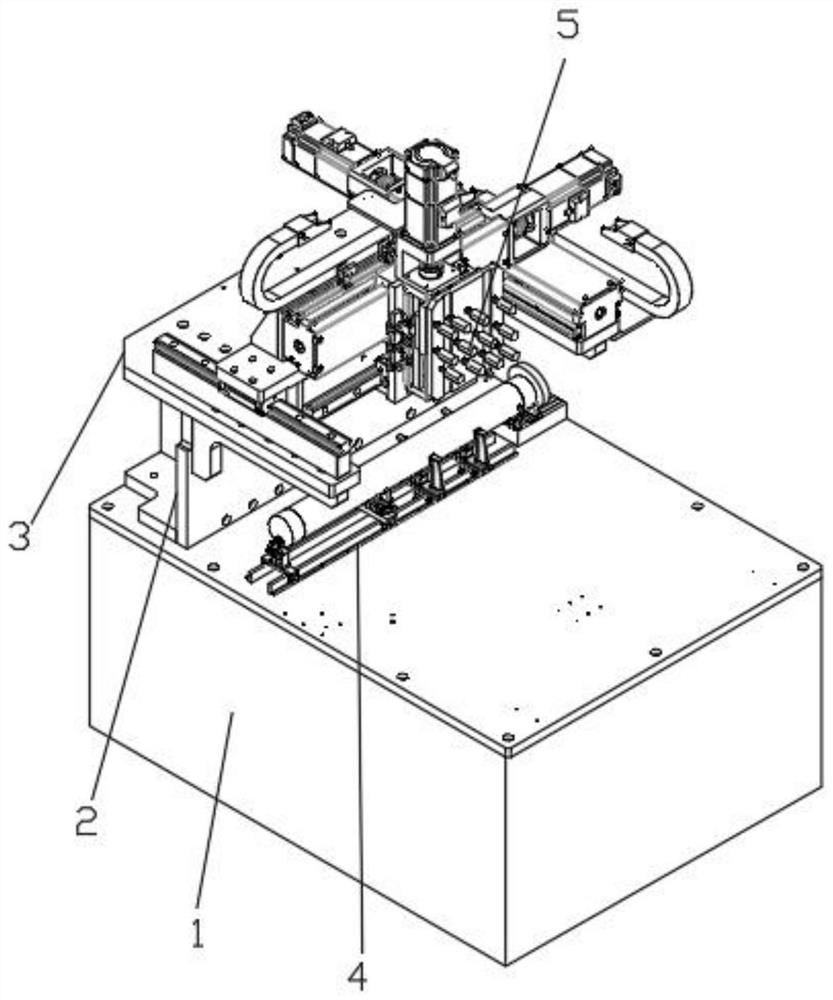

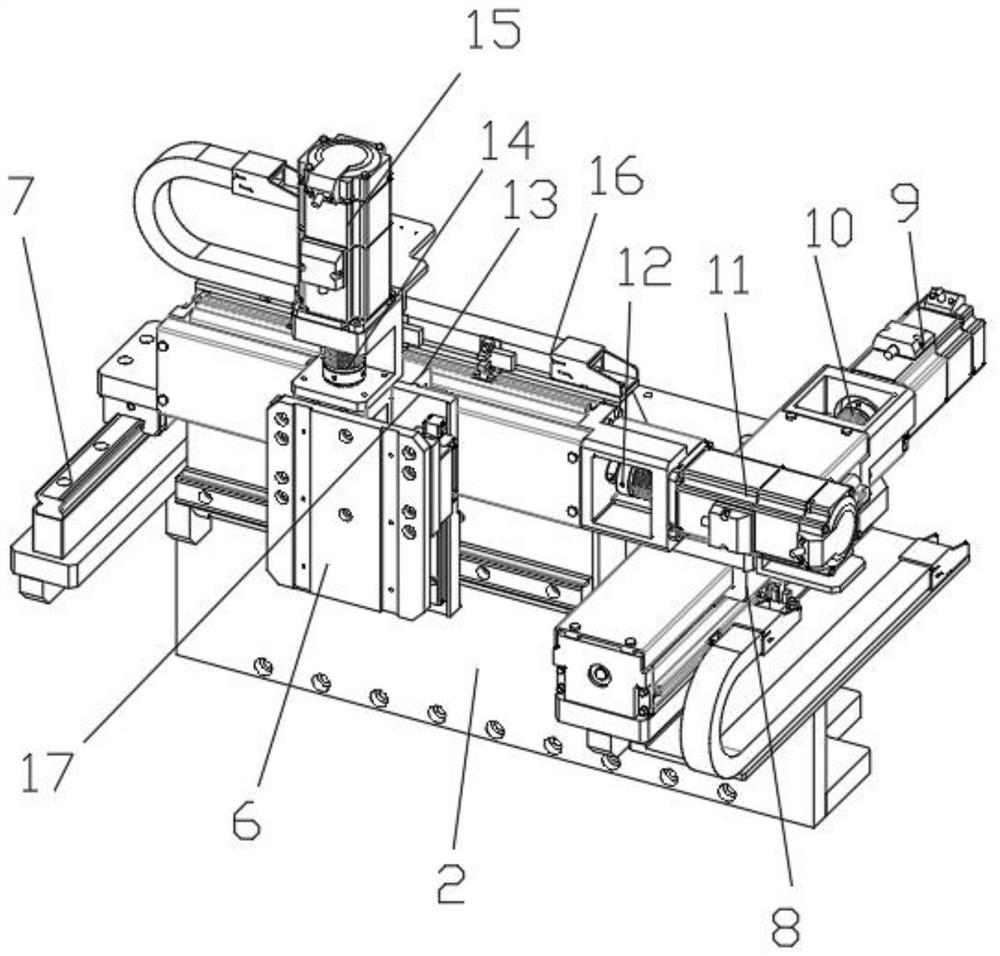

Semi-automatic sandblasting device

A sandblasting device, a semi-automatic technology, is applied to explosion generating devices, used abrasive treatment devices, spray guns, etc. It can solve the problems of long time required, uneven surface treatment of products, etc., and achieve good effect and sandblasting effect. Good, regular and beautiful effect on the surface of the tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

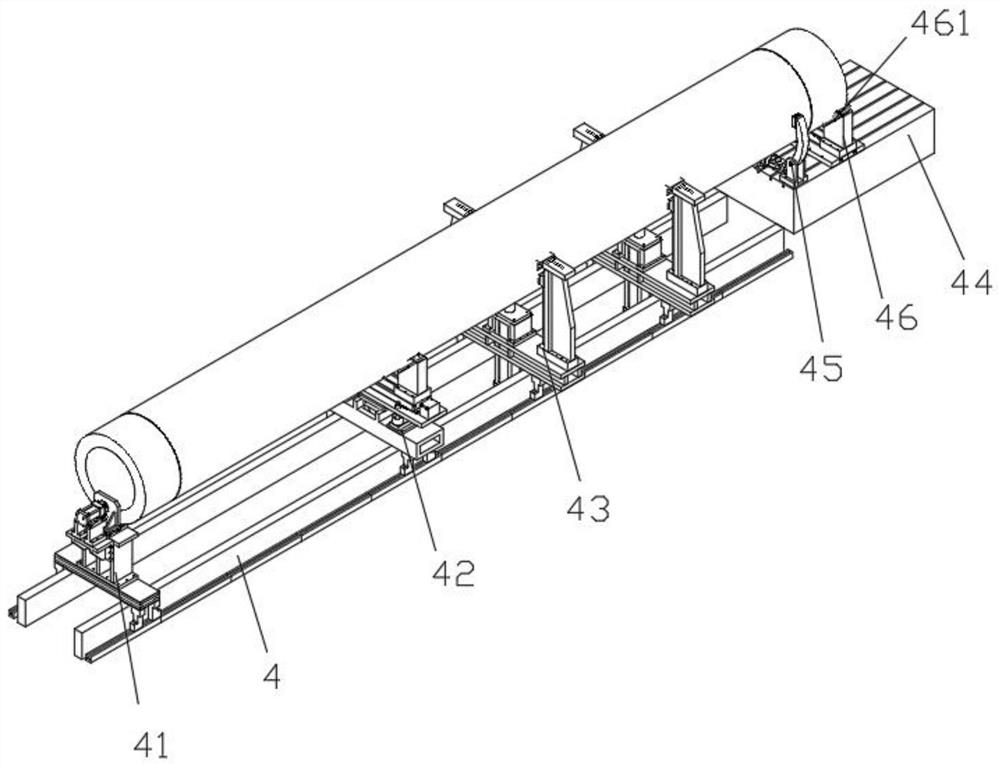

[0049] The working steps of the semi-automatic sandblasting device are:

[0050] Step 1. Drive cylinder 5 451, push the two arc-shaped plates 453 to move inward through the piston rods at both ends, until the fourth scraper 454 contacts the surfaces on both sides of the tank body, and the arc-shaped plates 453 are used to support the tank body function, the fourth scraper 454 is used to scrape sand on its surface; then drive the cylinder three 431 to push the lifting block 436 up, and drive two cylinder four 434 at the same time, and the two cylinder four 434 push the two movable blocks 435 to rotate to form a V Shaped structure, two movable blocks 435 are in contact with the bottom surface of the tank body, the two movable blocks 435 and the side plates 433 are used to support the tank body, and the third scraper 437 is in contact with the surface on both sides of the tank body; finally drive the cylinder Six 423, push the lifting seat 429 up and down, then drive the servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com