Weather-resisting matte PC/ASA alloy material

A kind of alloy material and weather-resistant technology, which is applied in the field of alloy materials, can solve the problems of influence, inability to meet the requirements of outdoor use, poor weather resistance, etc., and achieve the effect of solving alpine brittleness, meeting outdoor weather resistance requirements, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

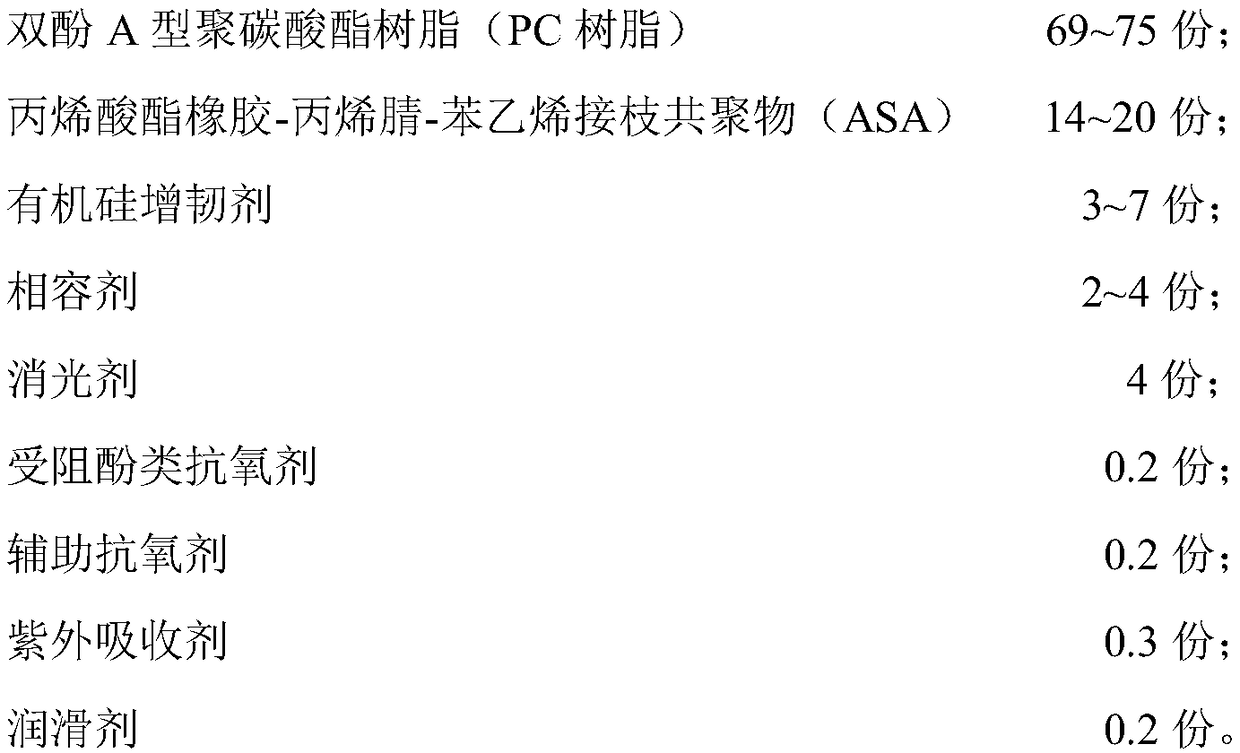

[0018] The raw material formula of the PC / ASA alloy material in this embodiment is shown in Table 1 below.

[0019] Table 1

[0020] raw material name

parts by mass

PC 122

75

ASA PW-978B

14

S2001

5

AX8900

2

BMAT

4

ADR-4370S

/

IRGANOX 1330

0.2

AO-412S

0.2

UV5411

0.3

P861 / 3.5

0.2

[0021] in FIG. 1:

[0022] PC 122 is a kind of PC resin produced by Taiwan Chimei Industrial Co., Ltd., with a melt index of 22g / 10min;

[0023] PW-978B is an ASA resin produced by Taiwan Chimei Industrial Co., Ltd., with a melt index of 12g / 10min;

[0024] S2001 is a silicone cold-resistant toughening agent produced by Mitsubishi Metaburen of Japan;

[0025] AX8900 is ethylene-methyl acrylate-glycidyl methacrylate produced by Arkema, France;

[0026] BMAT is a cross-linked styrene-acrylonitrile copolymer matting agent produced by Compton in the United States;

[0027] I...

Embodiment 2

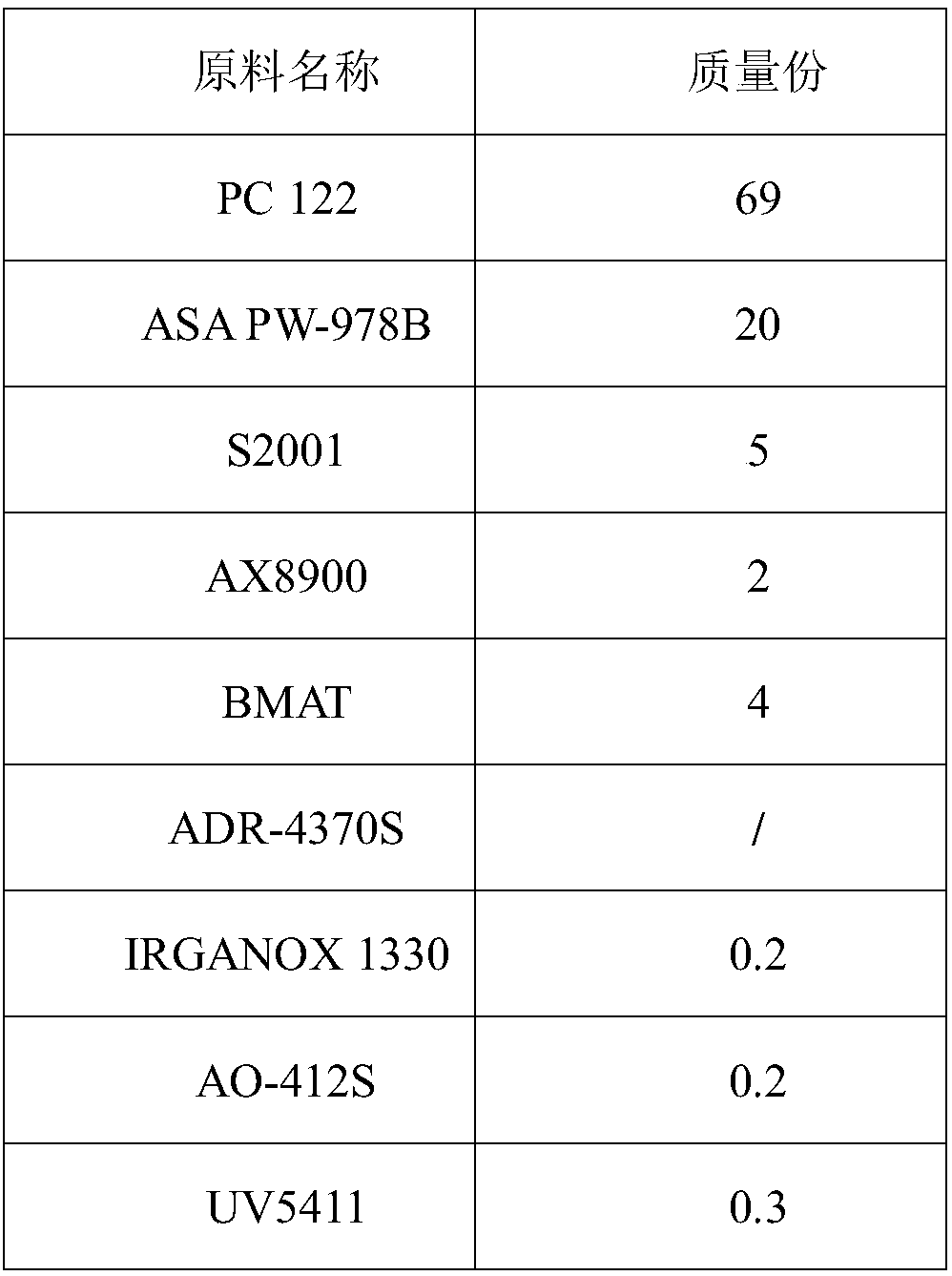

[0033] The raw material formulation of the PC / ASA alloy material in this embodiment is shown in Table 2 below.

[0034] Table 2

[0035] raw material name

parts by mass

PC 122

75

ASA PW-978B

14

S2001

5

AX8900

2

BMAT

4

ADR-4370S

0.1

IRGANOX 1330

0.2

AO-412S

0.2

UV5411

0.3

P861 / 3.5

0.2

[0036] In Table 2:

[0037] PC 122 is a kind of PC resin produced by Taiwan Chimei Industrial Co., Ltd., with a melt index of 22g / 10min;

[0038] PW-978B is an ASA resin produced by Taiwan Chimei Industrial Co., Ltd., with a melt index of 12g / 10min;

[0039] S2001 is a silicone cold-resistant toughening agent produced by Mitsubishi Metaburen of Japan;

[0040] AX8900 is ethylene-methyl acrylate-glycidyl methacrylate produced by Arkema, France;

[0041] BMAT is a cross-linked styrene-acrylonitrile copolymer matting agent produced by Compton in the United States;

[...

Embodiment 3

[0049] The raw material formulation of the PC / ASA alloy material in this embodiment is shown in Table 3 below.

[0050] table 3

[0051]

[0052]

[0053] In Table 3:

[0054] PC 122 is a kind of PC resin produced by Taiwan Chimei Industrial Co., Ltd., with a melt index of 22g / 10min;

[0055] PW-978B is an ASA resin produced by Taiwan Chimei Industrial Co., Ltd., with a melt index of 12g / 10min;

[0056] S2001 is a silicone cold-resistant toughening agent produced by Mitsubishi Metaburen of Japan;

[0057] AX8900 is ethylene-methyl acrylate-glycidyl methacrylate produced by Arkema, France;

[0058] BMAT is a cross-linked styrene-acrylonitrile copolymer matting agent produced by Compton in the United States;

[0059] IRGANOX 1330 is a hindered phenolic primary antioxidant produced by BASF in Germany;

[0060] AO-412S is a thioester auxiliary antioxidant produced by Japan Adico;

[0061] UV5411 is a UV329 absorber produced by Cytec;

[0062] P861 / 3.5 is a PETS lubrican...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com