A kind of silicon-modified matte UV resin and preparation method thereof

A silicon-modified resin technology, applied in the field of silicon-modified matte UV resin, can solve problems such as poor alignment and orientation of matting powder, unstable gloss, and blooming of the paint film surface, achieving good application prospects and high use value , the effect of not easy to change color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

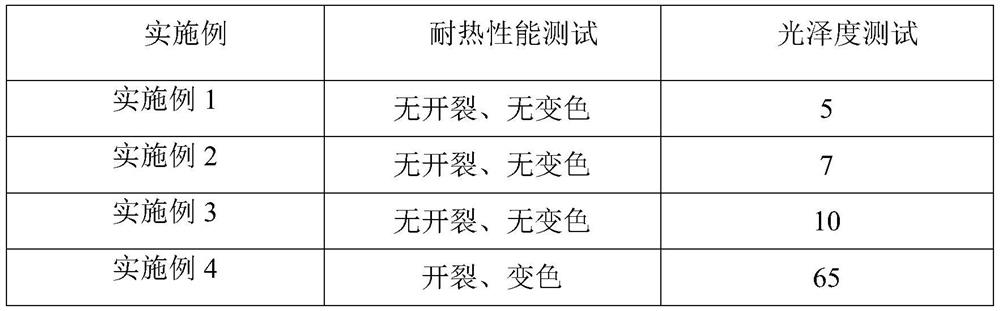

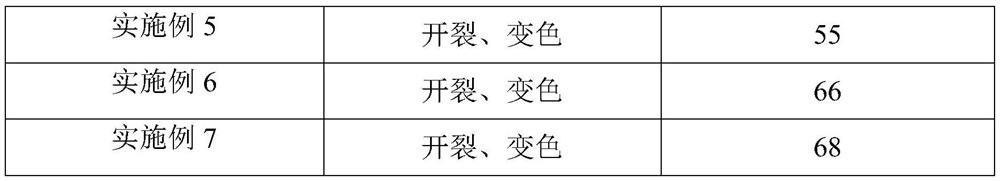

Examples

preparation example Construction

[0075] The present invention also provides the preparation method of above-mentioned resin, it comprises the following steps at least:

[0076] (1) Add crotonic acid, bisphenol A epoxy acrylate, 4-hydroxybutyl acrylate, ethyl isocyanate, N-(hydroxyethyl)-N-methylaminopropyltrimethoxysilane, bismuth isooctanoate Put it into the reaction kettle, stir and react for 2-3 hours at 80-90°C to obtain the silicon-modified resin intermediate;

[0077] (2) Put glycerin and hydrochloric acid into the silicon-modified resin intermediate obtained in step (1), and disperse for 1 to 2 hours at 60°C to 80°C under nitrogen protection;

[0078] (3) Cool the mixture obtained in step (2) to 40-50°C, add 4-tert-butylcatechol and continue to keep warm and disperse for 1-2 hours, then depressurize to a vacuum of 0.015-0.025MPa to dehydrate until anhydrous is formed So far, cooling to obtain polycondensate;

[0079] (4) Add hypromellose to the polycondensate obtained in step (3), reduce the temperat...

Embodiment 1

[0083] Embodiment 1 provides a silicon-modified matte UV resin, which is composed of the following raw materials in parts by weight: 25 parts of organosilicon monomers, 30 parts of resin intermediates, 20 parts of organic acids, 20 parts of polyols, the first catalyst 0.35 parts, 0.025 parts of the second catalyst, 0.08 parts of a polymerization inhibitor, 0.07 parts of a stabilizer, 7 parts of a neutralizing agent, and 18 parts of water.

[0084] The organosilicon monomer is N-(hydroxyethyl)-N-methylaminopropyltrimethoxysilane.

[0085] The N-(hydroxyethyl)-N-methylaminopropyltrimethoxysilane (CAS No. 330457-46-0) was purchased from Shanghai Shiyang Chemical Co., Ltd.

[0086] The resin intermediates are bisphenol A epoxy acrylate, 4-hydroxybutyl acrylate and ethyl isocyanate.

[0087] The weight ratio of the bisphenol A epoxy acrylate, 4-hydroxybutyl acrylate and ethyl isocyanate is 2:1:1.

[0088] The bisphenol A epoxy acrylate is produced by the company itself, and the n...

Embodiment 2

[0102] Embodiment 2 provides a silicon-modified matte UV resin. The difference from Example 1 is that in the resin raw material, there are 20 parts of organosilicon monomers, 25 parts of resin intermediates, 15 parts of organic acids, and 15 parts of polyols. 0.3 parts of the first catalyst, 0.02 parts of the second catalyst, 0.05 parts of a polymerization inhibitor, 0.05 parts of a stabilizer, 5 parts of a neutralizing agent, and 15 parts of water.

[0103] This example also provides a method for preparing a silicon-modified matte UV resin, the steps of which are similar to those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com