Rapid printing etching-resistant ink

An anti-etching and fast technology, applied in the field of coatings, can solve the problems of unable to further increase the winding speed, high gloss of printed patterns, no matte anti-sticking, etc., to achieve matte effect, good acid-etching effect, and curing fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

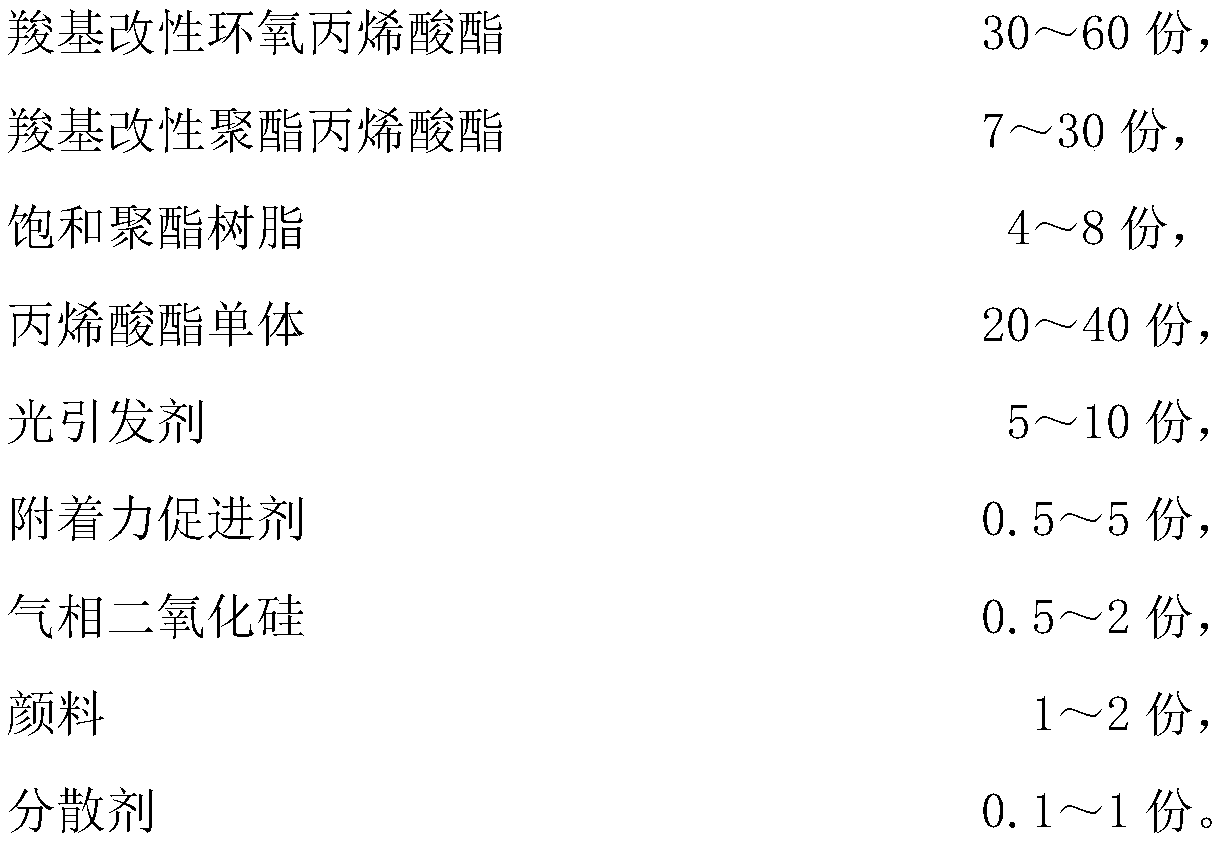

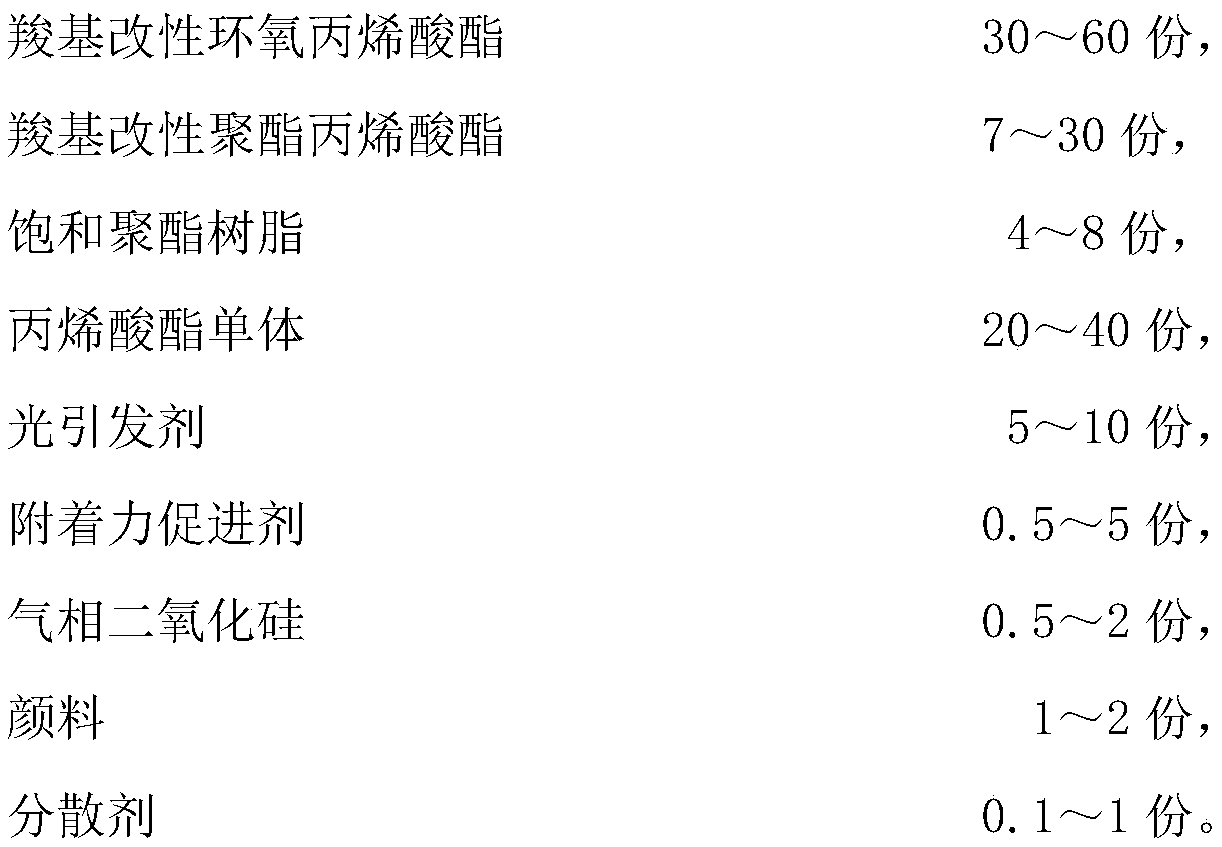

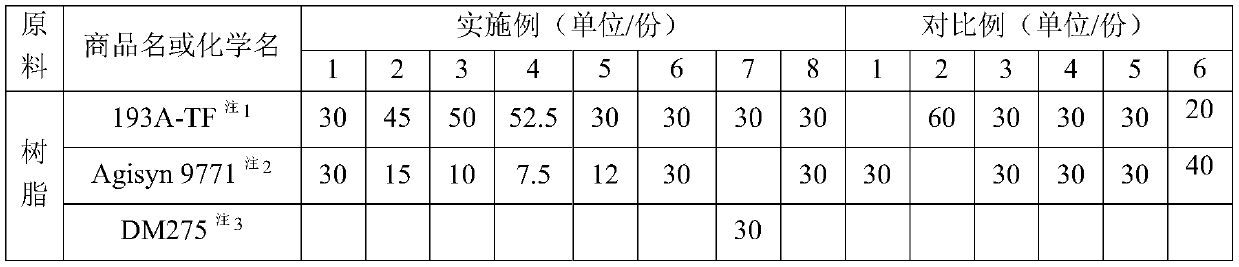

[0028] Embodiment 1-8 provides a kind of rapid printing anti-etching ink, and the corresponding raw material components and parts by weight of each composition are as shown in Table 1, and the preparation method is as follows:

[0029] Put the acrylate monomer and saturated polyester resin into a stainless steel reaction kettle, stir at 500rpm at 70°C until completely dissolved and then lower to room temperature; then add half of the dispersant and stir evenly, add the pigment and stir at a high speed at 2000rpm until Disperse evenly, and then use a sand mill to grind to prepare a color paste; put carboxyl-modified epoxy acrylate and carboxyl-modified polyester acrylate into a stainless steel reaction kettle, add the other half of the dispersant and stir until uniform, add gas phase two The silicon oxide is stirred at a high speed of 2000rpm to disperse evenly; finally, the above-prepared color paste and initiator are added, and stirred at a medium speed of 1000rpm to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com