A coating for zero-degree silica gel and preparation method thereof

A coating and silica gel technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems affecting the fastness of the coating, the dull appearance of the coating, and the peeling of the coating, so as to increase the smoothness of the hand, the delicate and uniform appearance, Good layer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

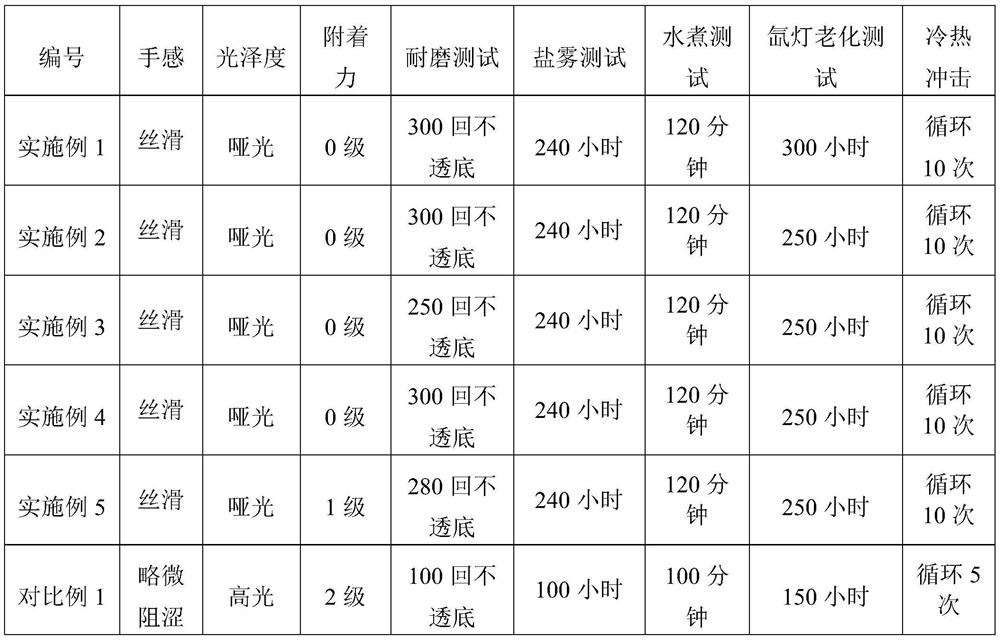

Examples

Embodiment approach

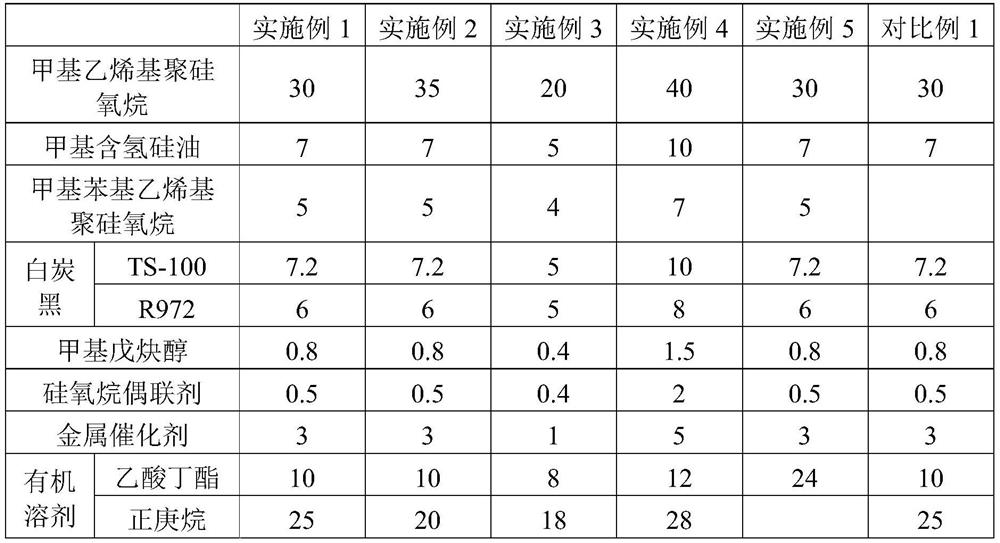

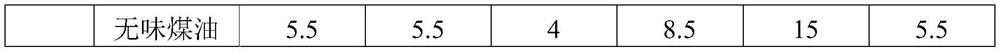

[0024] Among them, the methyl vinyl polysiloxane is the main film-forming substance, methyl hydrogen-containing silicone oil and methylphenyl vinyl polysiloxane are auxiliary film-forming substances, and the combination of the three can improve the white carbon black powder. It can improve the adhesion between the coating and the zero-degree silicone substrate, and enhance the flexibility of the coating film. In order to better achieve the above effects, the number average molecular weight of methyl vinyl polysiloxane is preferably 50,000 to 200,000, more preferably 100,000 to 150,000, and the vinyl content is preferably 0.1 to 0.3%, more preferably 0.1 to 100,000. 0.2%; the hydrogen content of methyl hydrogen-containing silicone oil is 0.5-1.5%, more preferably 0.5-1%; the molecular weight of methyl phenyl vinyl polysiloxane is 50,000-200,000, more preferably 10-20 Ten thousand. As an embodiment of the present invention, the methyl vinyl polysiloxane can be TSE221 or TSE260 ...

Embodiment 1-5

[0040] The paint preparation method is as follows:

[0041] (1) Weigh the raw materials according to the formula in Table 1, add methyl vinyl polysiloxane, methyl phenyl vinyl polysiloxane, methyl hydrogen-containing silicone oil, and organic solvent into the dispersion container, Stir for 5 to 10 minutes at rpm, then slowly add white carbon black TS-100 and R972 under stirring, stir at 1200 to 2000 rpm for 20 to 30 minutes, and finally add the inhibitor methylpentynol and silane coupling agent, stirring at 400-800 rpm for 5-10 minutes.

[0042] (2) Grind the mixture 2-3 times with a three-roll machine to make the coating fineness <15 μm.

[0043] (3) Add a metal catalyst to the mixture obtained in step (2), and stir at 100-300 rpm for 5-6 minutes to obtain a coating product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com