Matt vehicle interior decoration material and preparation method thereof

A car interior and matte technology, which is applied in the field of matte car interior materials and its preparation, can solve problems such as cost increase and environmental impact, and achieve the effects of reducing production costs and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

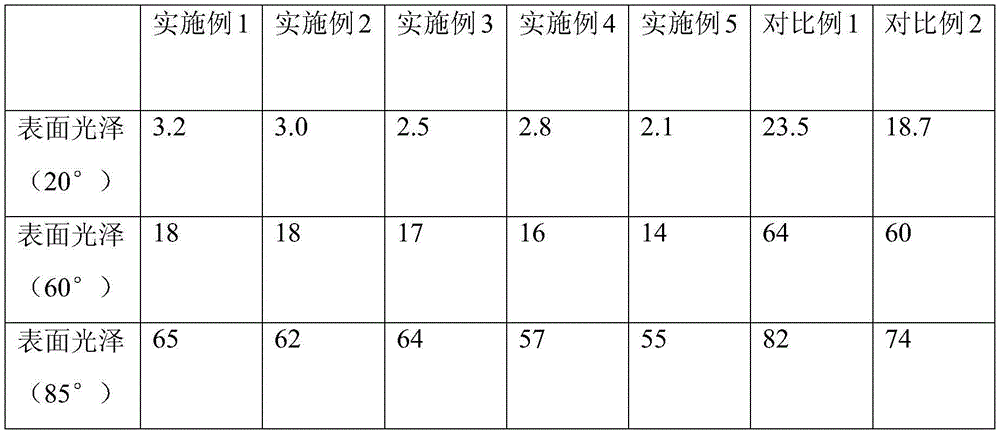

Examples

Embodiment 1

[0019] A matte automotive interior material, consisting of the following components by mass: 25 parts of PC resin, 27 parts of ABS resin, 5 parts of alkali-free glass fiber, 4 parts of stearyl stearate, polytetrafluoroethylene 6 parts, 4 parts of polydimethylsiloxane, 3-parts of antioxidant 168, 4 parts of antioxidant 1010.

[0020] Preparation:

[0021] (1) According to the above mass parts, add PC resin, ABS resin, alkali-free glass fiber, polytetrafluoroethylene, polydimethylsiloxane and antioxidant 168 into the mixing mixer, stir at a temperature of 130 ° C, and the speed Be 500r / min, obtain compound one;

[0022] (2) Add antioxidant 1010 and stearyl stearate to the mixture 1 obtained in step (1) within 20 minutes, mix at a temperature of 170° C., and rotate at a speed of 1500 r / min to obtain mixture 2;

[0023] (3) Extrude the mixture obtained in step (2) through a twin-screw extruder, cool, dry, and cut to obtain it. The temperature of the twin-screw extruder is set as...

Embodiment 2

[0025] A matte automotive interior material, consisting of the following components by mass: 34 parts of PC resin, 42 parts of ABS resin, 15 parts of medium-alkali glass fiber, 11 parts of pentaerythritol stearate, and 19 parts of polytetrafluoroethylene , 12 parts of polydimethylsiloxane, 12 parts of antioxidant 168, and 10 parts of antioxidant 1010.

[0026] Preparation:

[0027] (1) According to the above mass parts, add PC resin, ABS resin, medium alkali glass fiber, polytetrafluoroethylene, polydimethylsiloxane and antioxidant 168 into the mixing mixer, stir at a temperature of 160 ° C, and the speed Be 800r / min, obtain compound one;

[0028] (2) Add antioxidant 1010 and pentaerythritol stearate to the mixture 1 obtained in step (1) within 30 minutes, mix at a temperature of 210° C., and rotate at a speed of 1700 r / min to obtain mixture 2;

[0029] (3) Extrude the mixture obtained in step (2) through a twin-screw extruder, cool, dry, and cut to obtain it. The temperatur...

Embodiment 3

[0031] A matte automotive interior material, consisting of the following components by mass: 28 parts of PC resin, 29 parts of ABS resin, 6 parts of high-strength glass fiber, 7 parts of pentaerythritol stearate, 9 parts of polytetrafluoroethylene, 7 parts of polydimethylsiloxane, 4 parts of antioxidant 168, 5 parts of antioxidant 1010.

[0032] Preparation:

[0033] (1) According to the above mass parts, add PC resin, ABS resin, high-strength glass fiber, polytetrafluoroethylene, polydimethylsiloxane and antioxidant 168 into the mixing mixer, stir at a temperature of 140 ° C, and the rate is 600r / min, obtain compound one;

[0034] (2) Add antioxidant 1010 and pentaerythritol stearate to the mixture 1 obtained in step (1) within 25 minutes, mix at a temperature of 180° C., and rotate at 1600 r / min to obtain mixture 2;

[0035] (3) Extrude the mixture obtained in step (2) through a twin-screw extruder, cool, dry, and cut to obtain it. The temperature of the twin-screw extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com