Matte water-in-water base paint, preparation method and matte water-in-water paint

A technology of water-in-water and base paint, which is applied in the field of matte water-in-water paint, preparation, and matte water-in-water base paint. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

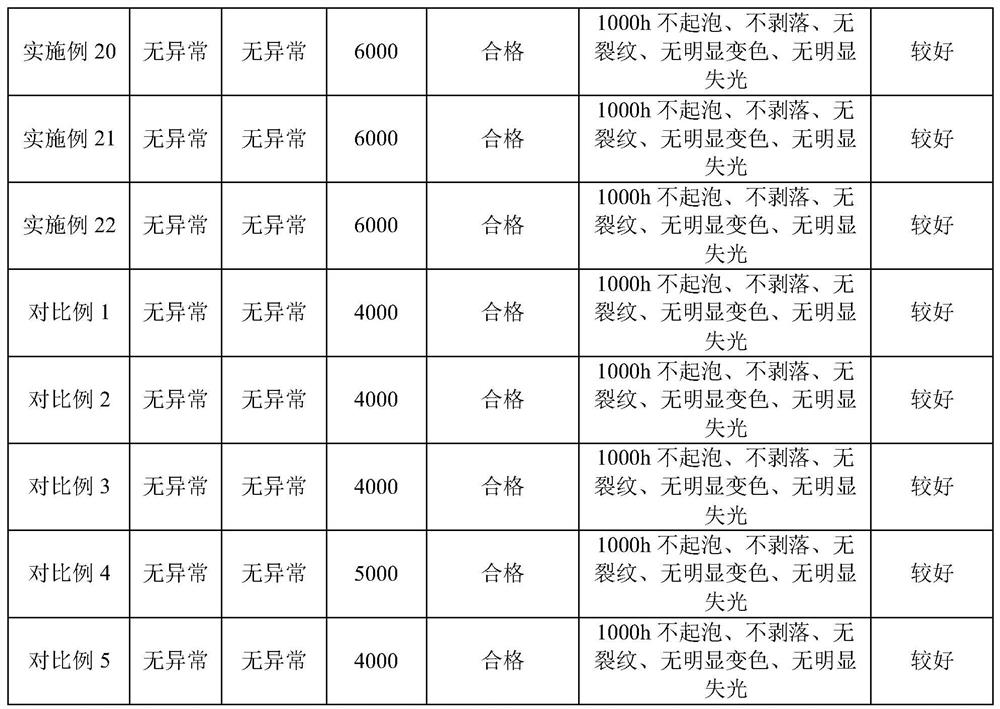

Examples

Embodiment 1

[0035] A kind of matte water-in-water base paint, it obtains by following processing steps:

[0036] Add 43.3kg of deionized water into the mixing tank, start the mixer, and add 300g of dispersant, 300g of defoamer, 1kg of antifreeze, 1.3kg of film-forming aids, and 0.5 kg, 2kg of titanium dioxide, 5kg of kaolin and 1.2kg of hydroxyethyl cellulose, stirred and dispersed for 5 minutes; added 1.5kg of multifunctional amine, and stirred at a high speed of 1500r / min for 20 minutes to obtain mixture A;

[0037] Add 37kg of emulsion, 400g of preservative, 6kg of 10wt% protective colloid solution and 200g of thickener in sequence to Mixture A at a rotating speed of 1000r / min, and stir and disperse for 10min at a rotating speed of 1000r / min to obtain dumb A light water-in-water base paint.

Embodiment 2

[0039] The preparation operation of the matte water-in-water base paint of embodiment 2 is exactly the same as that of embodiment 1, the difference is: 42.8 kg of deionized water in the raw material, 1 kg of expanded vitrified microbeads, and the rest are the same as embodiment 1.

Embodiment 3

[0041] The preparation operation of the matte water-in-water base paint of embodiment 3 is exactly the same as that of embodiment 1, the difference is: 42.3 kg of deionized water in the raw material, 1.5 kg of expanded vitrified microspheres, and the rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com