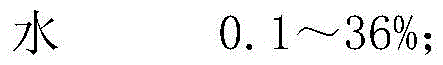

Two-component water-based matte finish varnish and preparation method thereof

A matt finish varnish, two-component technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

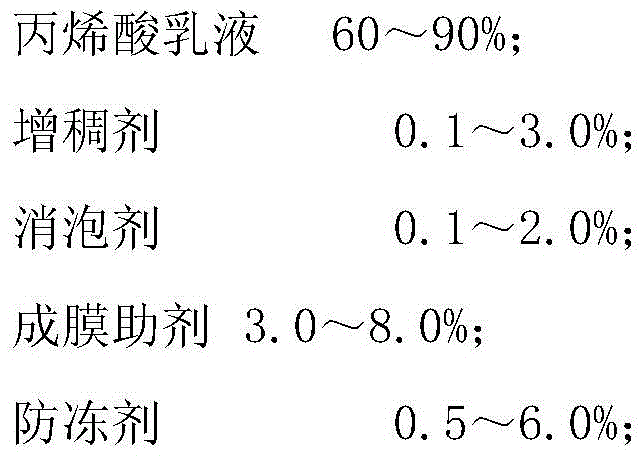

[0025] The two-component water-based matte finish varnish of the present embodiment comprises A, B components, and each raw material of A, B components is as follows:

[0026]

[0027] In the above component A, Henkel 2800 emulsion is used for acrylic emulsion; polyurethane thickener SN-612NC is used as thickener; silicone defoamer BYK024 is used as defoamer; alcohol ester twelve is used as film-forming aid; Propylene glycol is used; in the above-mentioned component B, anhydrous calcium chloride is used as a flocculant; tap water is used as water.

[0028] The preparation method of the two-component water-based matte finish varnish of the present embodiment may further comprise the steps:

[0029] (1) Prepare component A, specifically: weigh the raw materials of component A according to the weight ratio, first add water to the container, add acrylic emulsion, film-forming aids, antifreeze and defoamer while stirring, 300- Stir at 500rmp for 5 minutes until uniform dispersi...

Embodiment 2

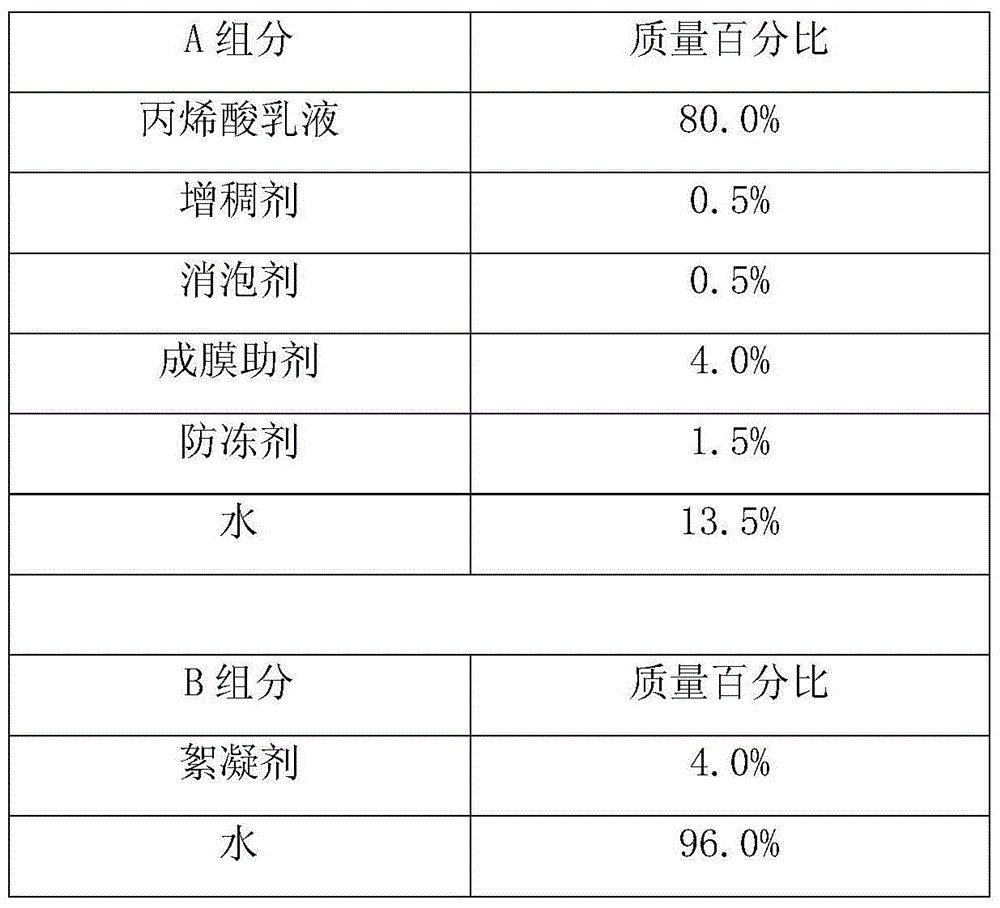

[0033] The two-component water-based matte finish varnish of the present embodiment comprises A, B components, and each raw material of A, B components is as follows:

[0034]

[0035] The above-mentioned acrylic emulsion adopts Henkel 2800 emulsion; the thickener adopts alkali swelling thickener TT935; the defoamer adopts organosilicon defoamer BYK024; Polyaluminum chloride; Water adopts tap water.

[0036] The preparation method of the two-component water-based matte finish varnish of the present embodiment may further comprise the steps:

[0037] (1) Prepare component A, specifically: weigh the raw materials of component A according to the weight ratio, first add water to the container, add acrylic emulsion, film-forming aids, antifreeze and defoamer while stirring, 300- Stir at 500rmp for 5 minutes until uniform dispersion, then add thickener, stir at 300-700rmp for 5 minutes and mix evenly to obtain component A;

[0038] (2) Preparation of component B, specifically: ...

Embodiment 3

[0041] The two-component water-based matte finish varnish of the present embodiment comprises A, B components, and each raw material of A, B components is as follows:

[0042]

[0043]

[0044] The above-mentioned acrylic emulsion adopts Henkel 2800 emulsion; the thickener adopts alkali swelling thickener ASE60; the defoamer adopts organosilicon defoamer BYK024; 35% polydimethyldiallylammonium chloride solution; tap water is used for water.

[0045] The preparation method of the two-component water-based matte finish varnish of the present embodiment may further comprise the steps:

[0046] (1) Prepare component A, specifically: weigh the raw materials of component A according to the weight ratio, first add water to the container, add acrylic emulsion, film-forming aids, antifreeze and defoamer while stirring, 300- Stir at 500rmp for 5 minutes until uniform dispersion, then add thickener, stir at 300-700rmp for 5 minutes and mix evenly to obtain component A;

[0047] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com