Matting powder-free ultra-matte skin feeling UV coating and preparation and curing method thereof

A technology of ultra-matte skin feeling and matting powder, which is applied in polyester coatings, epoxy resin coatings, antifouling/underwater coatings, etc., and can solve the problem of inability to achieve matte glossy skin feel, stain resistance, scratch resistance, etc. problem, to achieve a uniform matte effect, no dust pollution, and a good skin feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

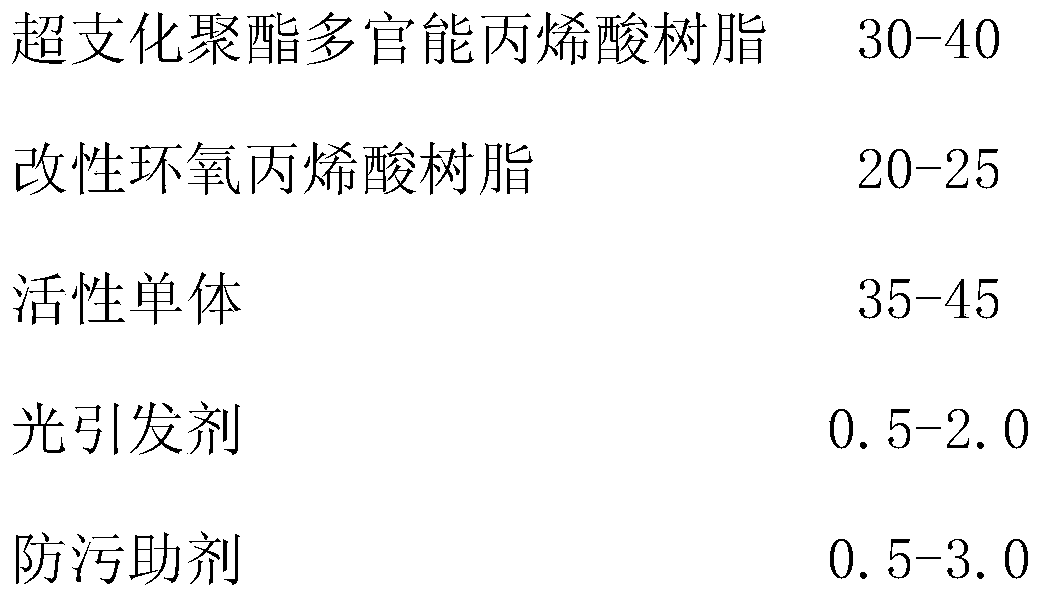

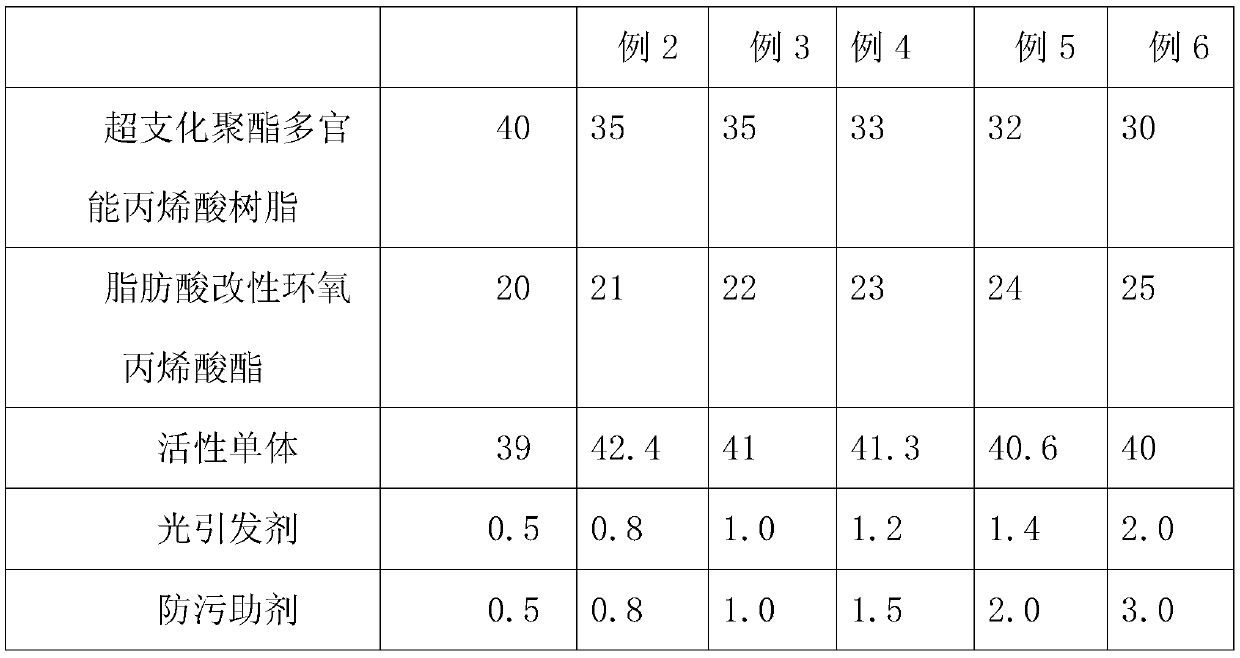

[0022] Concrete embodiment: following embodiment provides a kind of super matt skin feeling UV coating of exempting matting powder, comprises each component of following parts by weight:

[0023]

[0024] The hyperbranched polyester multifunctional acrylic resin is a hyperbranched polyester multifunctional acrylate whose end group is modified by succinic anhydride.

[0025] The modified epoxy acrylate resin is fatty acid modified epoxy acrylate.

[0026] The active monomer is one of trimethylolpropane triacrylate, tripropylene diacrylate, 1,6-hexanediol diacrylate, hydroxyethyl methacrylate, hydroxyethyl acrylate or its mixture.

[0027] The photoinitiator is one of 2-hydroxy-methylphenylpropane-1-one, 1-hydroxycyclohexane phenyl ketone, methyl benzoylformate or a mixture thereof.

[0028] The anti-fouling additive is a mixture of acrylate functional group silicone additives and fluorine-modified additives that can participate in crosslinking reactions.

[0029] The foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com