Total diffuse reflection matt coating material for thermal transfer and application and application method thereof

A coating material, diffuse reflection technology, applied in the direction of coating, polyurea/polyurethane coating, temperature recording method, etc., to achieve a completely matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

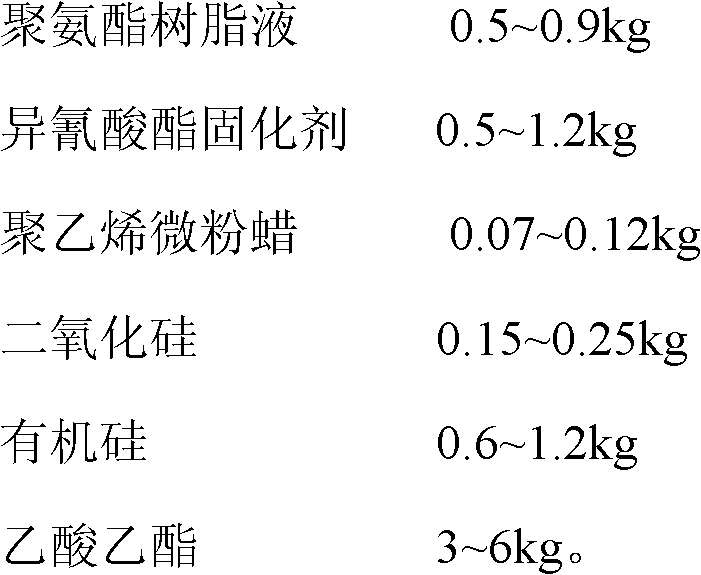

[0020] A kind of fully diffuse reflective matte coating material for thermal transfer, the weight of each component is as follows:

[0021]

[0022] An application of the above-mentioned totally diffuse reflective matte coating material for thermal transfer, which is used to prepare a matte coated film.

[0023] A method for using a fully diffuse reflective matte coating material for heat transfer, the steps of which are:

[0024] Step 1, adding the coating materials of the above ratio into the mixer for stirring;

[0025] Step 2, utilizing a coating machine to coat on the polyester film;

[0026] Step 3: Baking in an oven.

[0027] In the above use method, the stirring condition in the mixer is: stirring at 1400 rpm for 10 minutes, then stirring at 800 rpm for 10 minutes.

[0028] In the above using method, the oven baking condition is: baking in an oven at 60° C. for 60 hours. Example 2

Embodiment 2

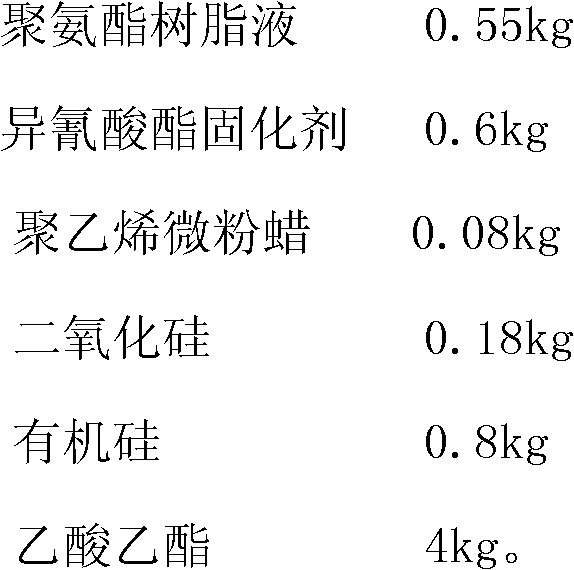

[0029] In the present embodiment, coating material, the weight meter of each component is as follows:

[0030]

[0031] Others are the same as in Example 1.

Embodiment 3

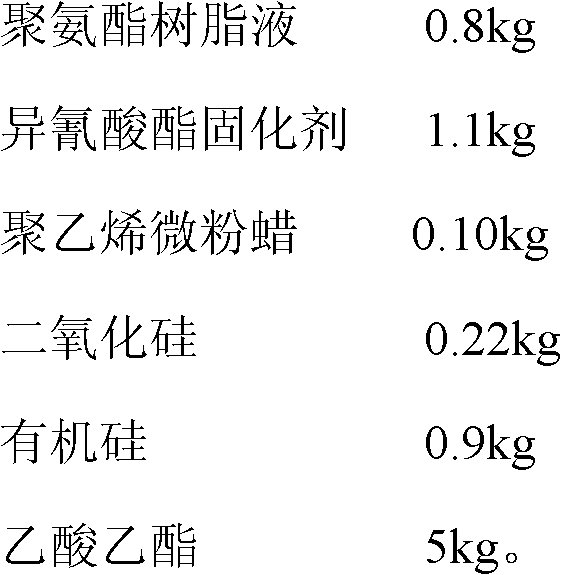

[0033] In the present embodiment, coating material, each component by weight is as follows:

[0034]

[0035] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com