Liquid crystal display and manufacturing method thereof

A liquid crystal display and substrate technology, applied in the direction of static indicators, etc., can solve problems such as poor picture uniformity, and achieve the effect of increasing picture uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

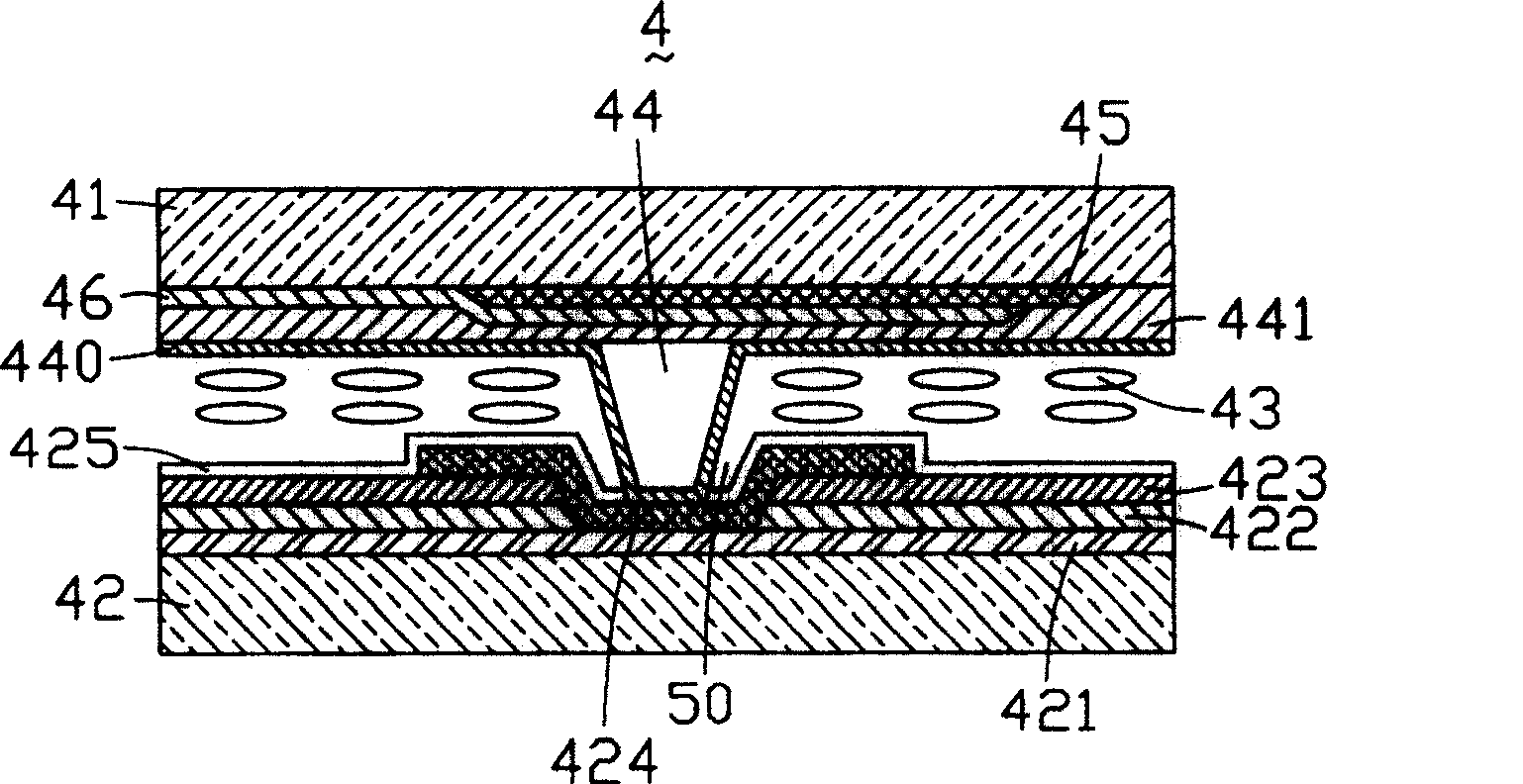

[0015] see image 3 , is a cross-sectional view of an embodiment of the liquid crystal display of the present invention. The liquid crystal display 4 includes a first substrate 41, a color filter 45 and a black matrix 46 positioned on the first substrate 41, a second substrate 42 opposite to the first substrate 41, and a second substrate 42 positioned on the first substrate 41. and the liquid crystal layer 43 between the second substrate 42 .

[0016] A first protection layer 441 is disposed on the color filter 45 and the black matrix 46 , and the first protection layer 441 has photosensitive spacers 44 arranged at intervals. The photosensitive spacer 44 is a plurality of inverted trapezoidal bumps, and a first transparent conductive film 440 is disposed on the outer side thereof. The first transparent conductive film 440 is usually made of ITO or IZO (IndiumZinc Oxide, IZO).

[0017] A common line (Common Line) 421 , an insulating layer 422 , a second protective layer 423 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com