Yttrium oxide thin film and preparation thereof

An yttrium oxide and thin film technology, applied in the field of yttrium oxide thin film and its preparation, can solve problems such as incompatibility, and achieve the effects of less environmental pollution, uniform film formation, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Yttrium oxide film and its synthesis, dissolving 0.3830g of yttrium nitrate hexahydrate in 100mL of deionized water, stirring to make a molar concentration of 0.01mol L -1 yttrium salt solution. Take 10 mL of the above-mentioned yttrium salt solution, and control the solution temperature at 40° C. by means of a constant temperature water bath. Yttrium oxide thin films were deposited using a three-electrode electrochemical cell. The working electrode is a single crystal silicon wafer. The counter electrode is a high-purity platinum electrode. The reference electrode is Ag / AgCl / saturated KCl solution electrode. Insert the three electrodes into the yttrium salt solution and keep the temperature constant for 30 minutes. The voltage range was adjusted between -0.85V (vsAg / AgCl / KCl reference electrode), and the deposition time was controlled within 1 hour. The deposited films were washed with deionized water and dried. Subsequently, the film was annealed and sintered at...

Embodiment 2

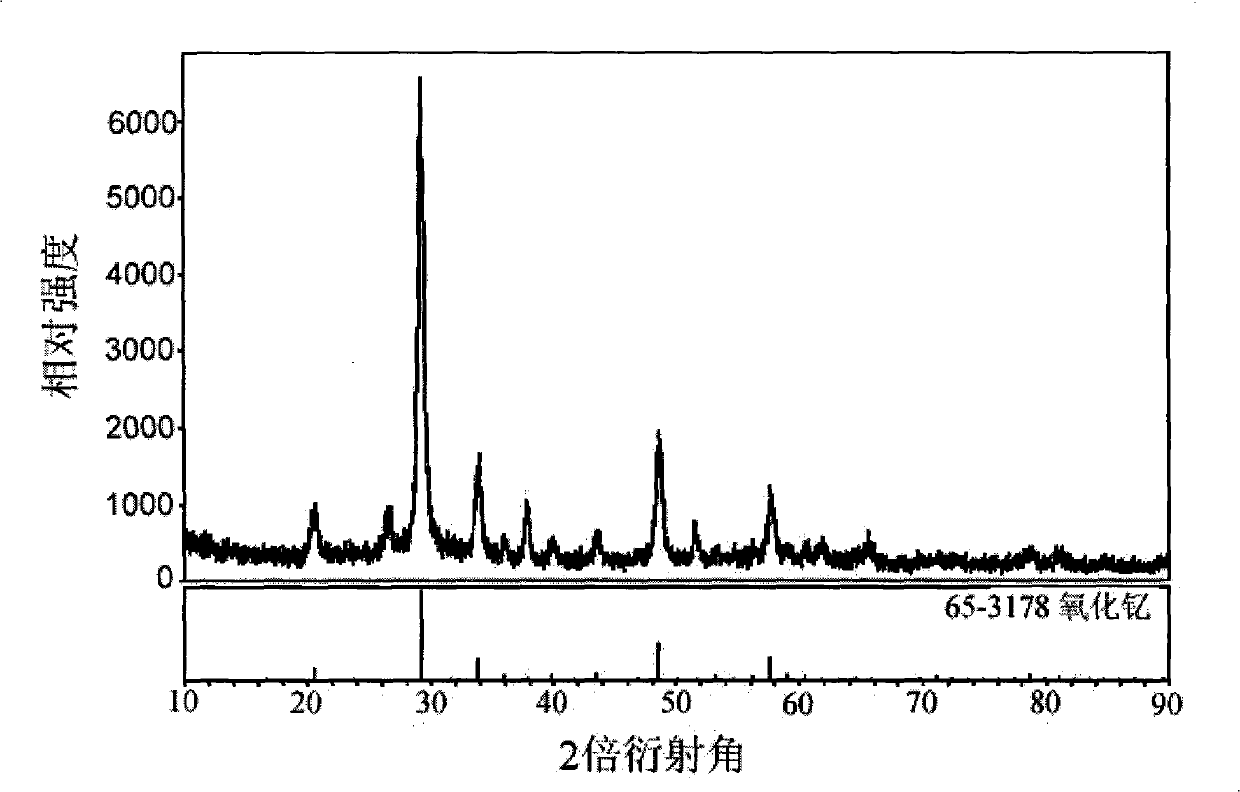

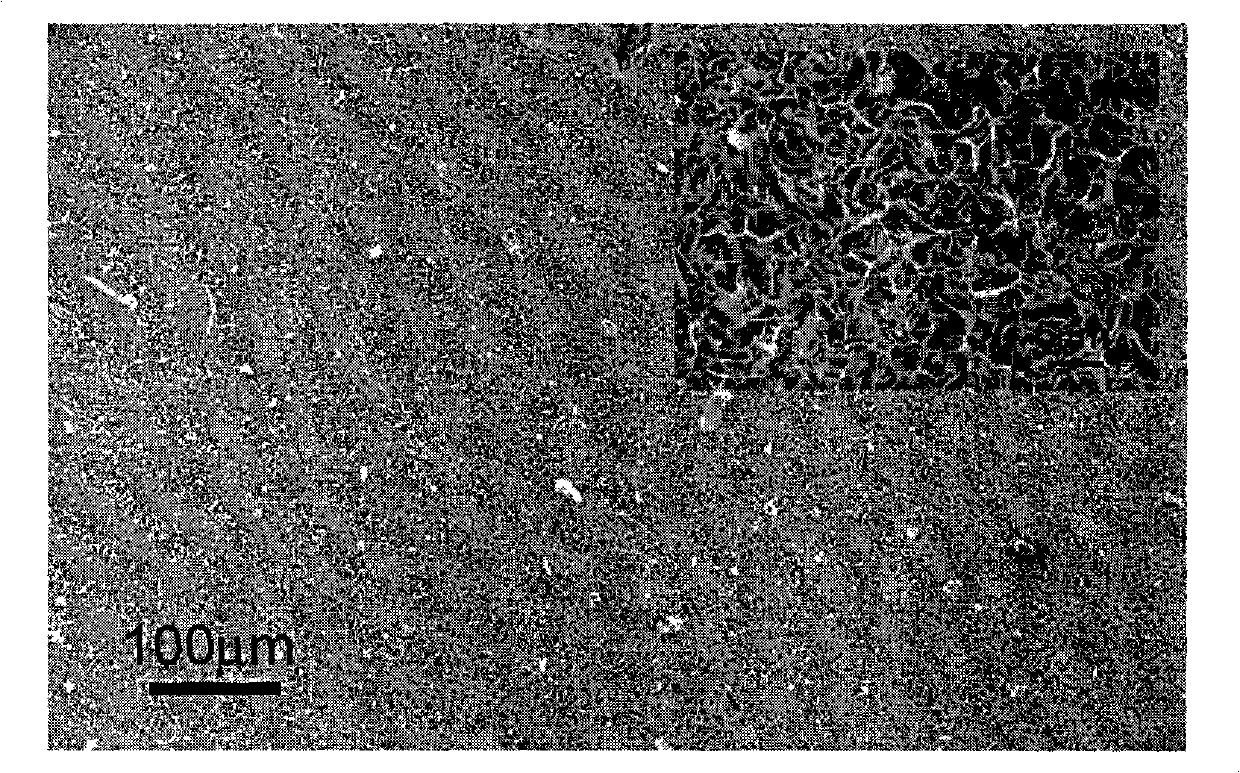

[0027] Yttrium oxide thin film and its synthesis, 15.1678g yttrium chloride hexahydrate was dissolved in 100mL deionized water, stirred, and the molar concentration was 0.5mol L -1 yttrium salt solution; take 10mL of the above yttrium salt solution, and control the solution temperature at 80°C by a constant temperature water bath. Yttrium oxide thin films were deposited using a three-electrode electrochemical cell. The working electrode is a single crystal silicon wafer. The counter electrode is a high-purity platinum electrode. The reference electrode is Ag / AgCl / saturated KCl solution electrode. Insert the three electrodes into the europium salt solution and keep the temperature constant for 30 minutes. Adjust the voltage between -1.4V (vs Ag / AgCl / KCl reference electrode), and control the deposition time at 20 minutes. The deposited films were washed with deionized water and dried. Subsequently, the film was annealed and sintered at 1000 °C for 30 min. Figure 4 It is t...

Embodiment 3

[0029] Yttrium oxide film and its synthesis, 3.8300g of yttrium nitrate hexahydrate was dissolved in 100mL of deionized water, stirred, and the molar concentration was 0.1mol L -1 yttrium salt solution. Take 10 mL of the above-mentioned yttrium salt solution, and control the solution temperature at 40° C. by means of a constant temperature water bath. Yttrium oxide thin films were deposited using a three-electrode electrochemical cell. The working electrode is a single crystal silicon wafer. The counter electrode is a high-purity platinum electrode. The reference electrode is Ag / AgCl / saturated KCl solution electrode. Insert the three electrodes into the yttrium salt solution and keep the temperature constant for 30 minutes. The voltage range was adjusted between -1.15V (vsAg / AgCl / KCl reference electrode), and the deposition time was controlled at 40 minutes. The deposited films were washed with deionized water and dried. Subsequently, the film was annealed and sintered a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com