Manufacturing equipment for anti-counterfeit traceable labels

A technology for manufacturing equipment and labels, which is applied in the field of manufacturing equipment for anti-counterfeiting traceability labels, and can solve the problems of burrs on dots, inability to realize the transfer process of lithographic printing ink, and unsightly text strokes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

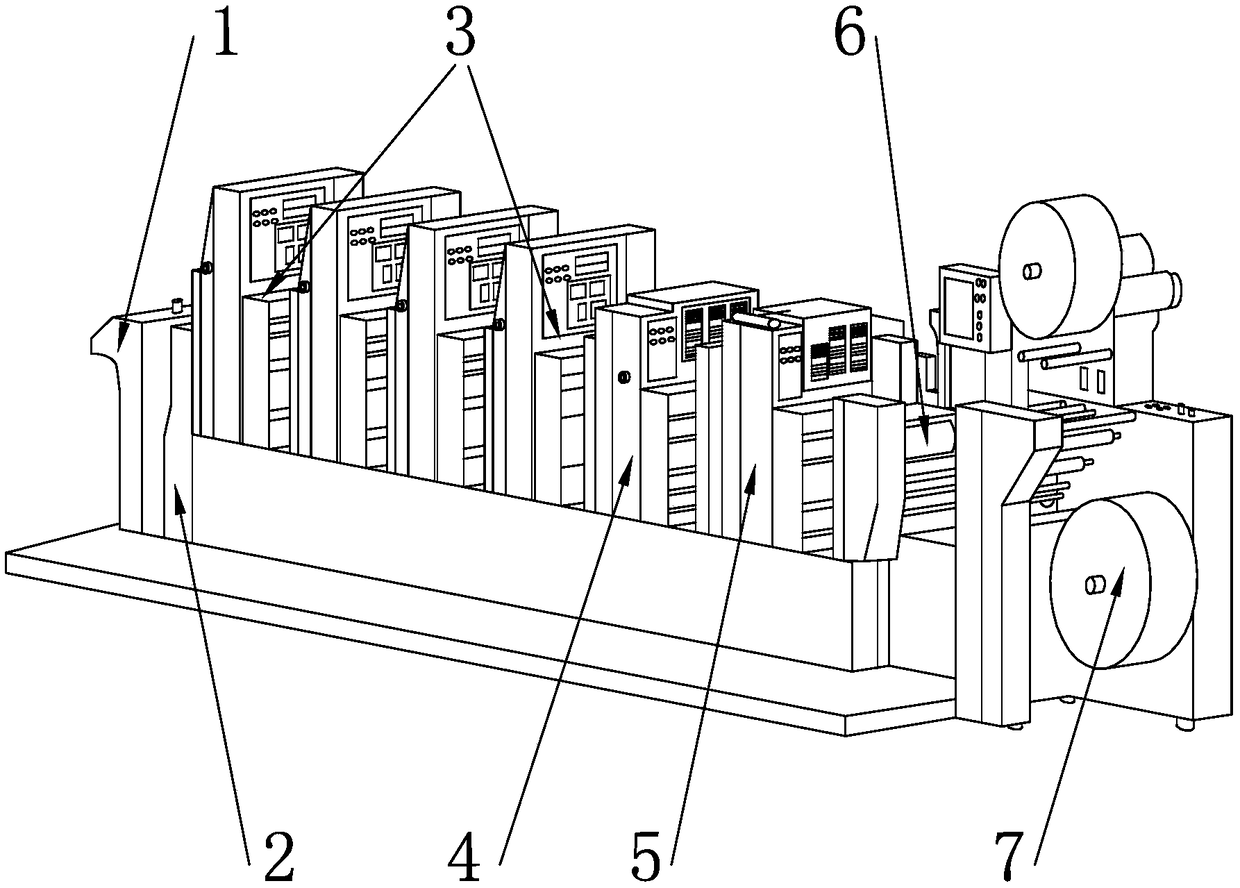

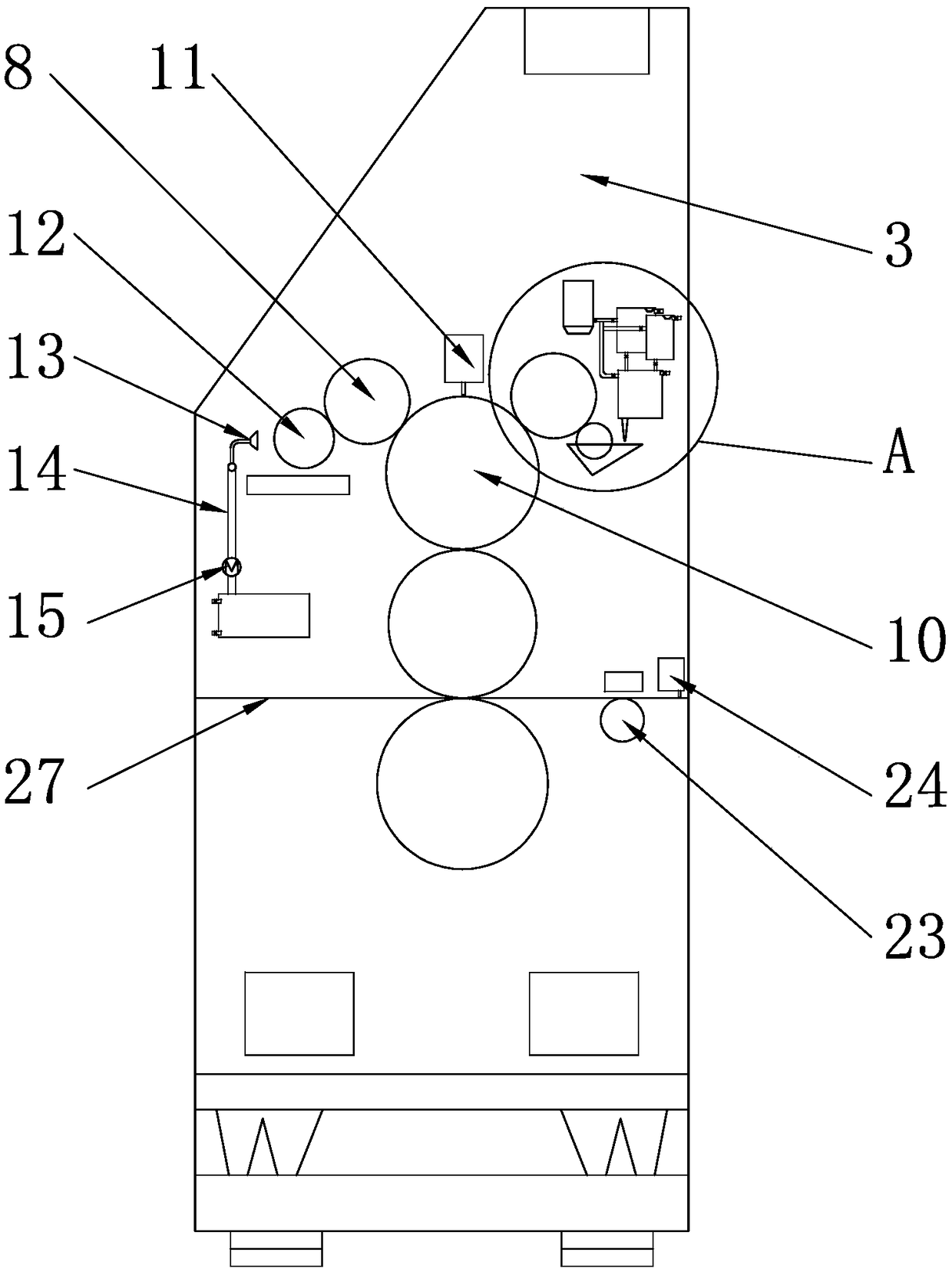

[0018] see figure 1 , a kind of anti-counterfeit traceable label manufacturing equipment of the present invention, along the conveying direction of label paper 27, be provided with paper feeding mechanism 1, paper feeding mechanism 2, printing mechanism 3, glazing mechanism 4, die-cutting mechanism 5, paper output mechanism 6 and delivery mechanism 7, the printing mechanism 3 can print the anti-counterfeit tracing pattern on the label paper 27.

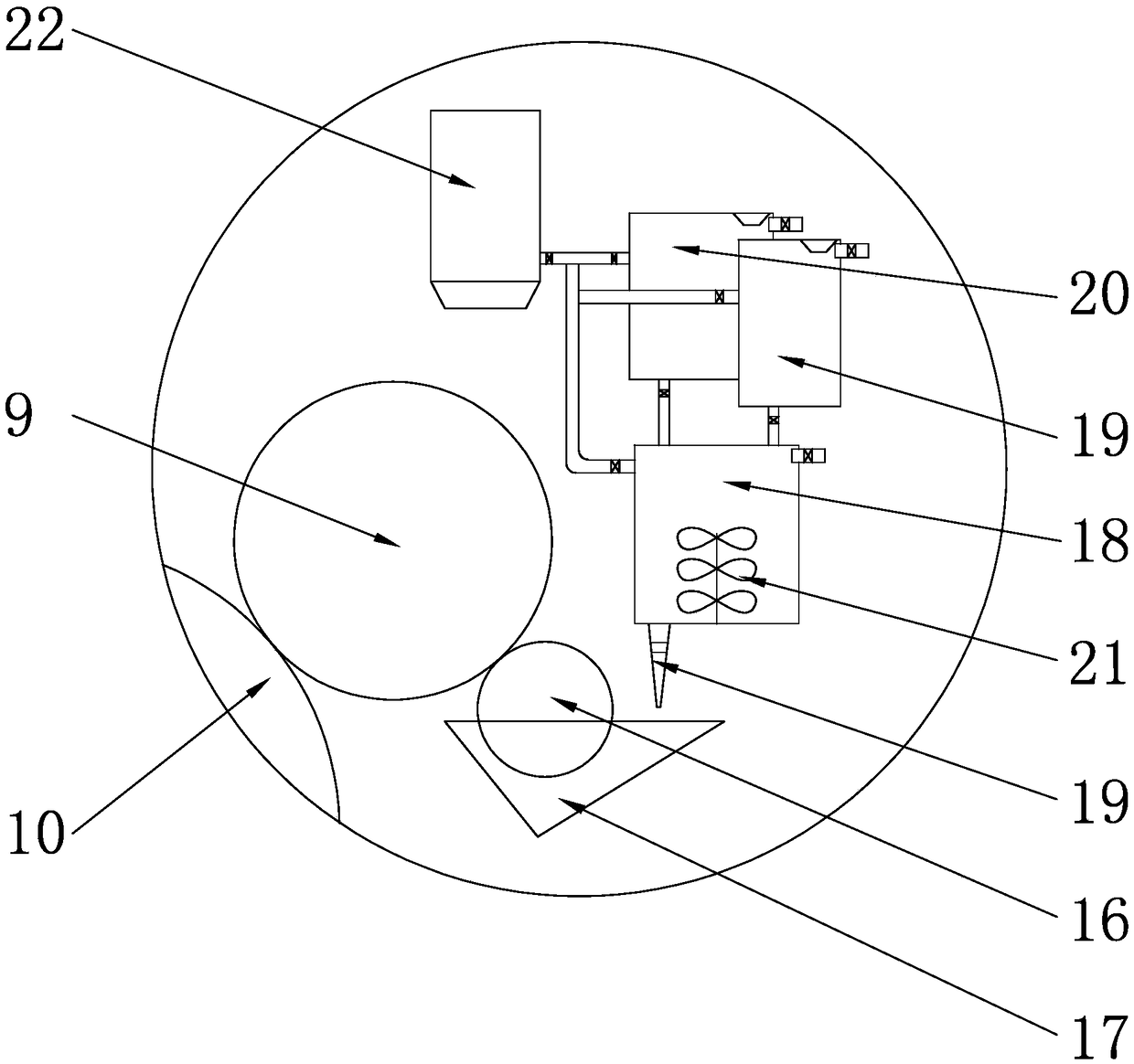

[0019] Since the size of the anti-counterfeit traceability pattern on the anti-counterfeit traceability label is small, it needs to be printed clearly enough, and the identification instrument can recognize the anti-counterfeit traceability information in the pattern, so as to achieve the purpose of anti-counterfeit traceability of the label. The viscosity and emulsification degree of the ink used in printing and the drying speed of the ink after printing all affect the printing quality. Therefore, these three aspects are adjusted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com