A chalk film sticking machine

A film laminating machine and chalk technology, which is applied in the types of packaging items, transportation and packaging, packaging, etc., can solve the problems of affecting the surrounding environment, affecting, falling off chalk dust, etc., to achieve the effect of reducing production costs, easy operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

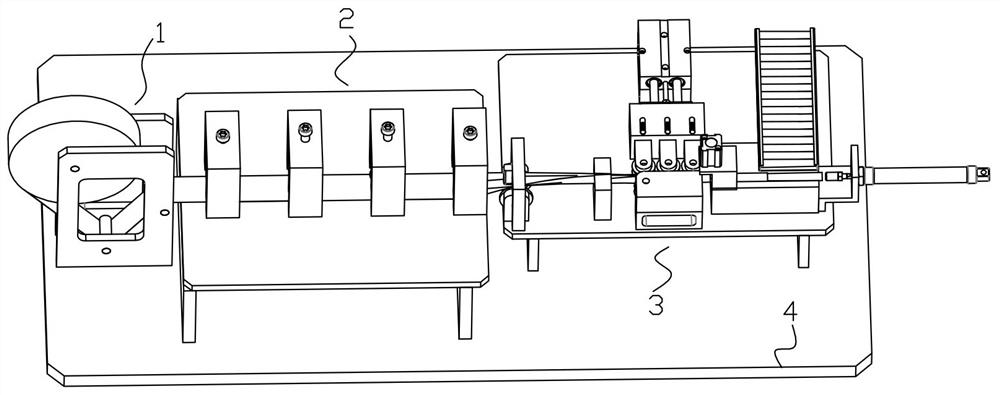

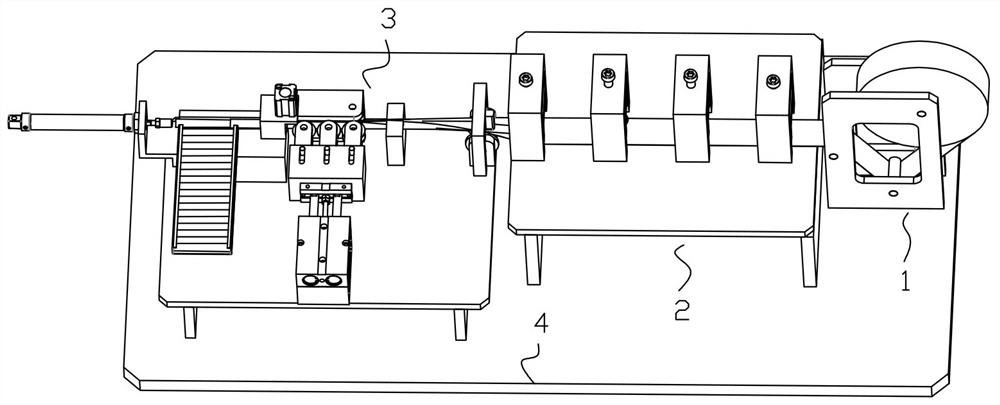

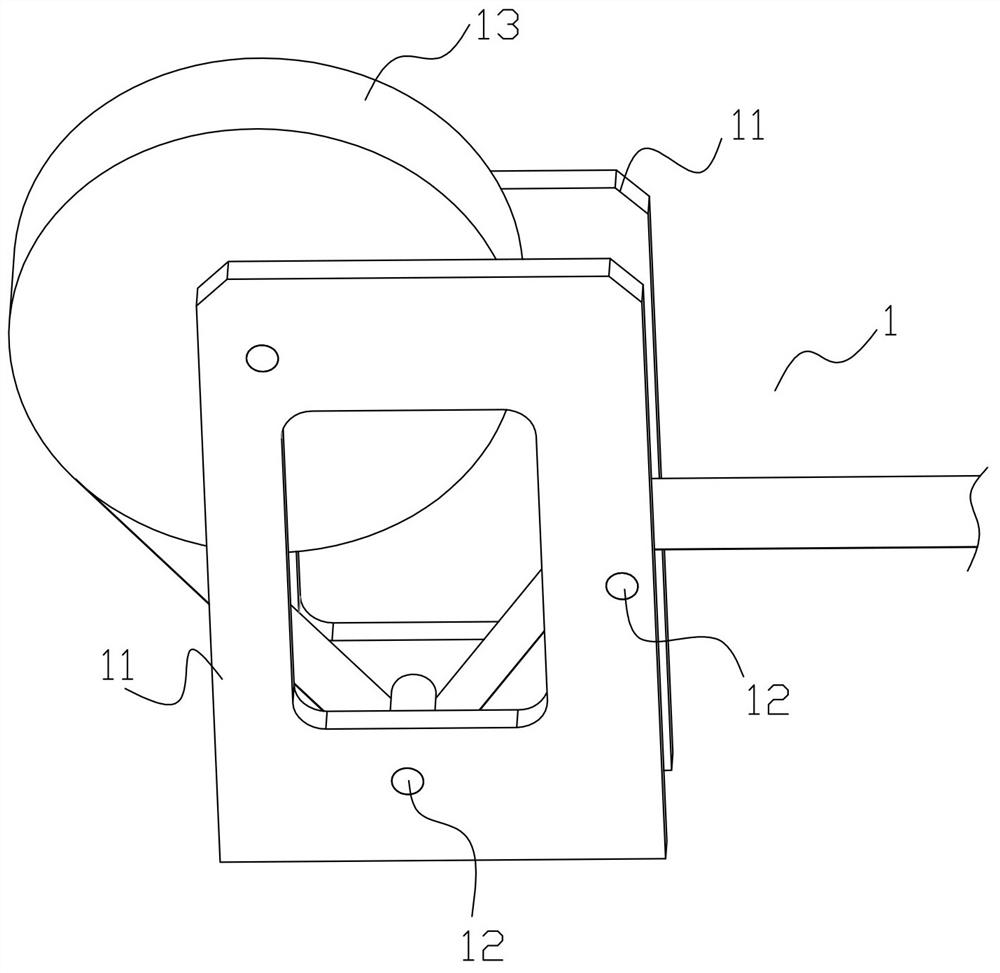

[0035] Such as Figure 1 to Figure 17 As shown, a kind of chalk laminating machine described in the present embodiment includes a heat-shrinkable film feeding mechanism 1, and the heat-shrinkable film feeding mechanism 1 includes two feeding vertical plates 11 arranged side by side, and the two shafts are connected to two The roll material drum 12 between the feeding vertical plates 11, the heat-shrinkable film material roll 13 axially connected between the two feeding vertical plates 11;

[0036] It also includes a heat-shrinkable film processing mechanism 2, which includes a door-shaped support frame 21, two pressing members 22, a longitudinal slit member 23 and a transverse slit member 24, the two presses The material members 22 are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com