Bagged material stacking line

A stacking and material technology, applied in the field of automation equipment, can solve the problems of bagged materials being stacked, inconvenient for operators to carry and store, and bagged materials are not stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

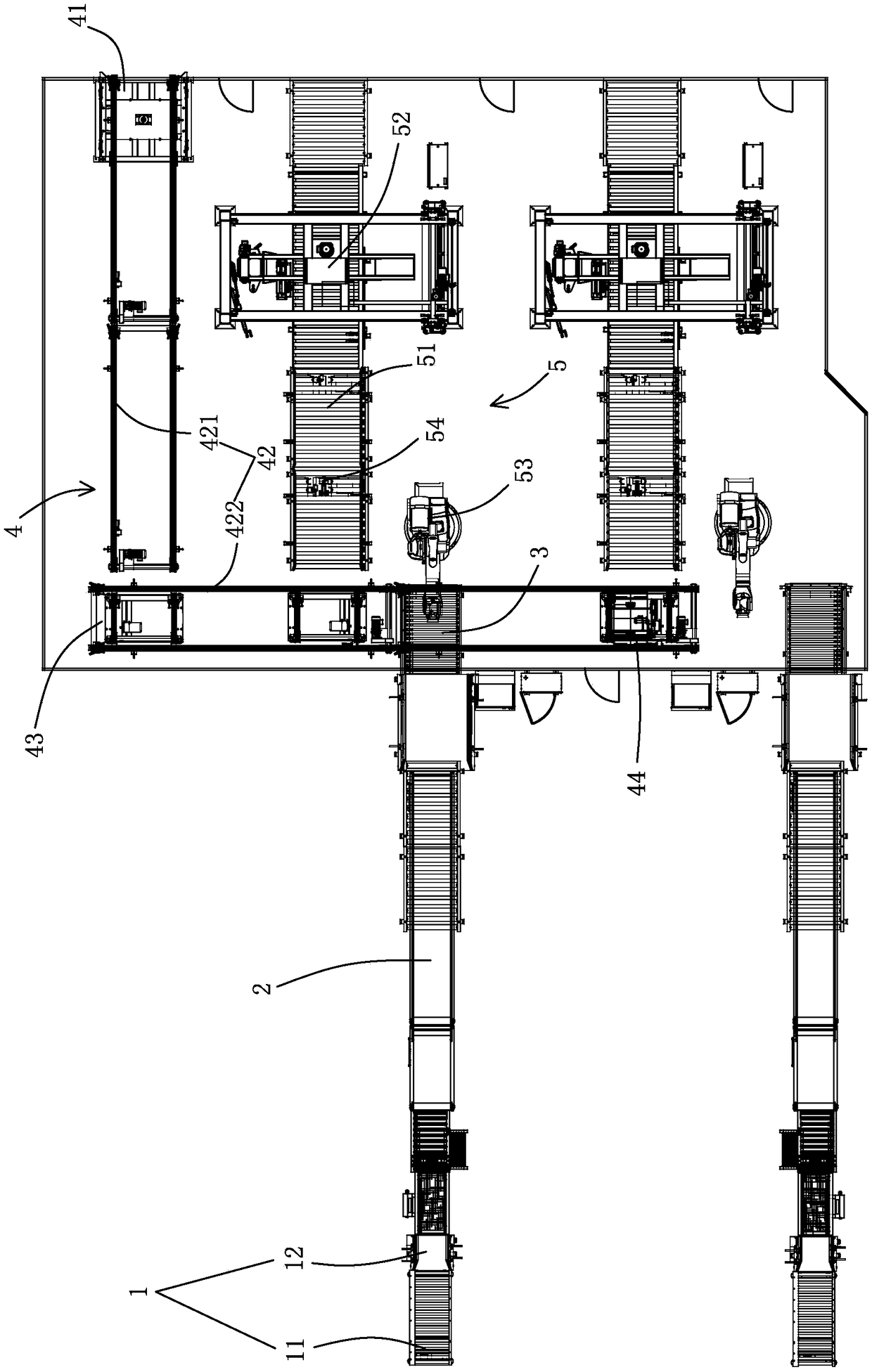

[0025] Such as Figure 1 to Figure 4 The palletizing line for bagged materials shown includes leveling conveying station 1, diverting conveying station 2, platform 3 to be coded, pallet conveying station 4 and stacking station 5.

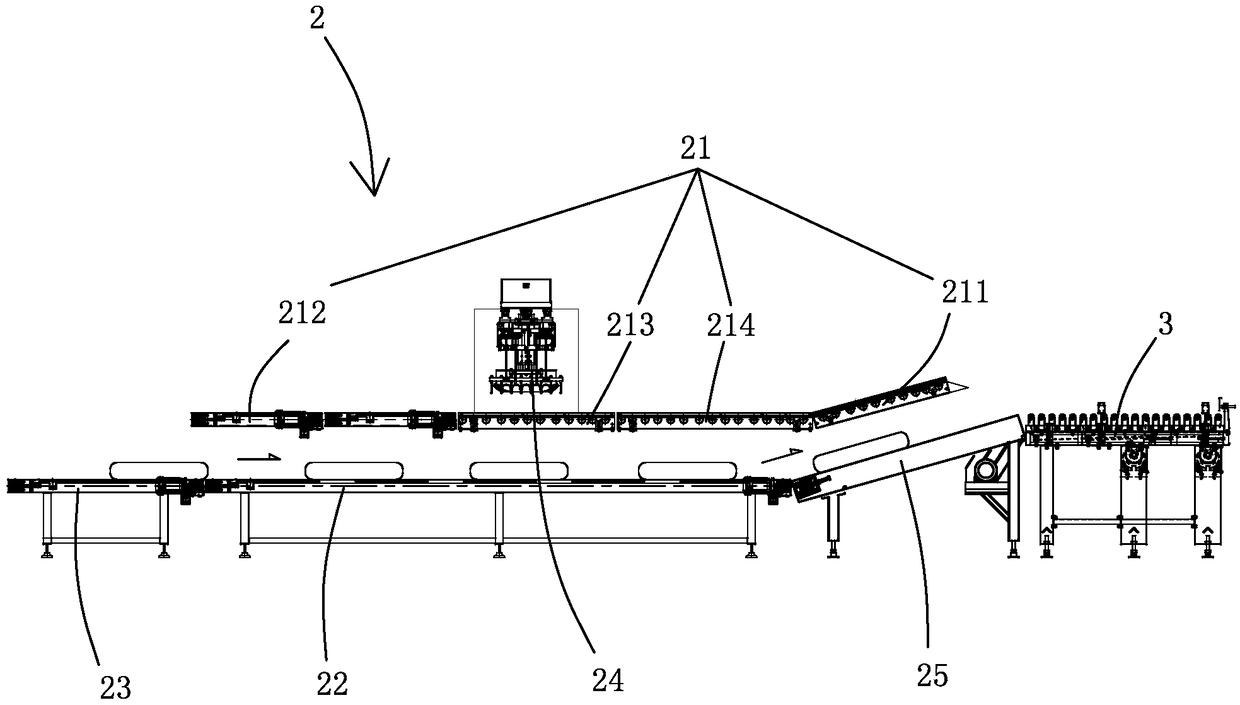

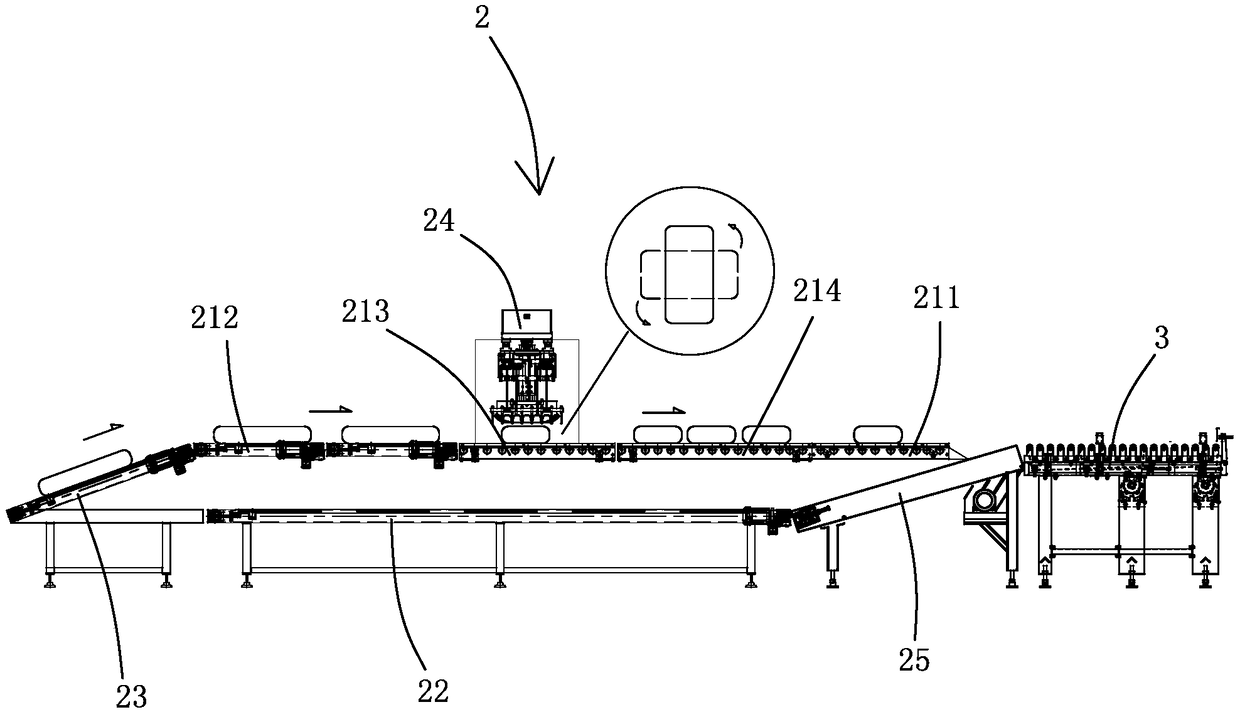

[0026] The leveling conveying station 1 includes a first conveying line 11 and a pressing and shaping conveyor 12 located at the output end of the first conveying line 11. After the first conveying line 11 transports the bagged materials to the pressing and shaping conveyor 12, the pressing The bag shaping conveyor 12 squeezes the bagged material flat and outputs it. The bagged material palletizing line is equipped with a leveling conveying station to squeeze the bagged materials flat before palletizing, so that it is convenient for the palletizing station to stack the bagged materials smoothly during palletizing, effectively preventing stacking The bagged materials after stacking are dumped, which is convenient for the staff to carry and store in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com