Loading device and loading method

A technology of loading equipment and extending direction, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve problems such as inconvenience in loading and loading, and achieve the effect of simple structure, improved versatility and applicability, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

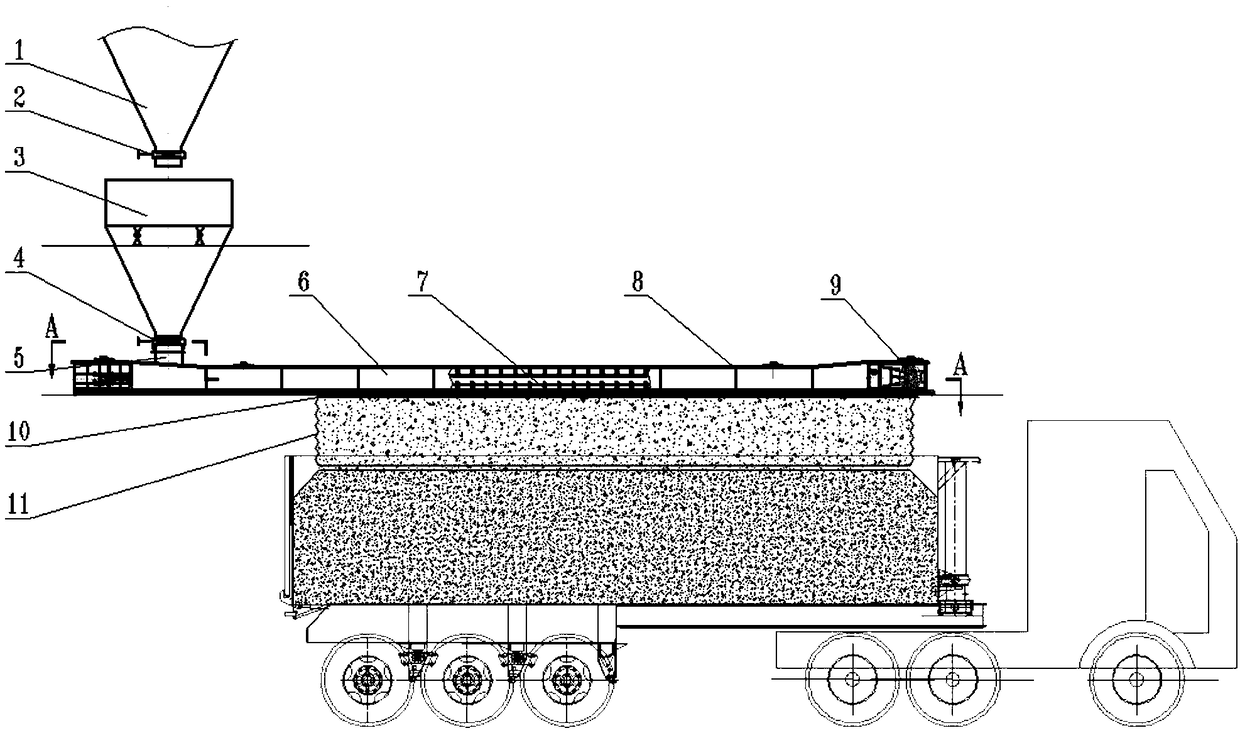

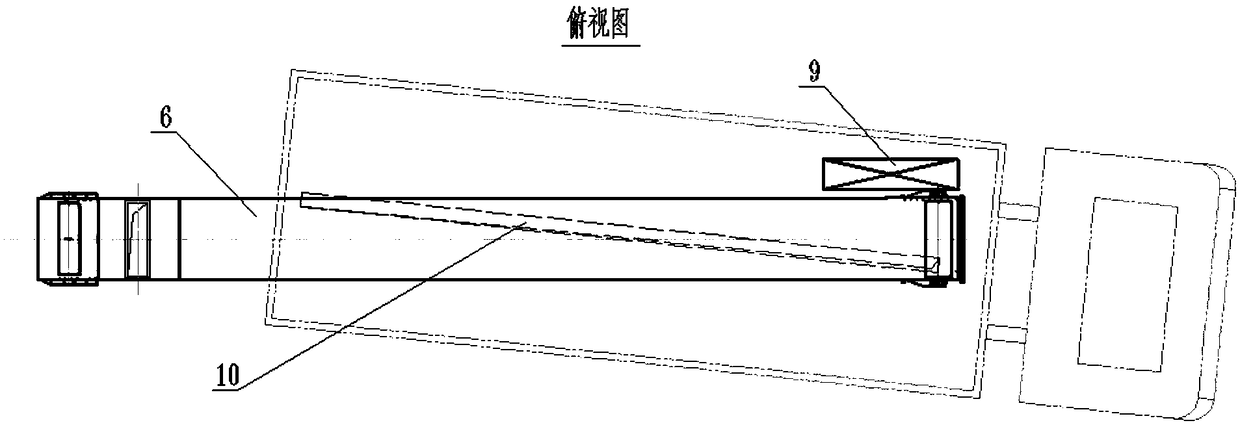

[0039] see figure 1 , image 3 and Figure 5 , provide a loading equipment and method, the loading equipment includes a buffer hopper 1, a first gate 2, a weighing bucket 3, a second gate 4, a distributor 5, a distributor 6, a scraper 7, a dust cover 11, the The scraper 7 has a distributing port 10. In actual application, the scraper 7 and the distributing port 10 can be designed separately. For example, the distributing port 10 is located below the scraper body. 6 or under the action of the driving device 9, movement, vibration or yaw movement occurs. The distribution port 10 has a distribution curve, and the extension direction of the distribution curve intersects with the extension direction of the scraper 7. Generally, relative to the material on the scraper 7. For the direction of movement, the material distribution curve is set obliquely, so the material will be unloaded into the loading vehicle in a dispersed manner, so as to achieve the purpose of uniform unloading a...

Embodiment 2

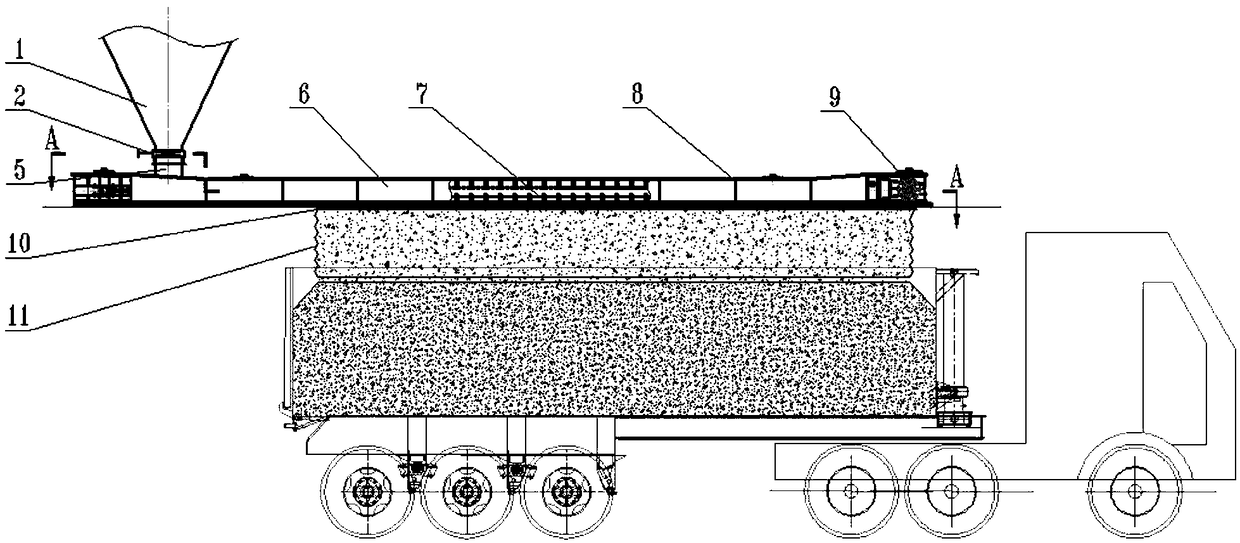

[0050] see figure 2 and Figure 5 , this embodiment provides a loading device and method, and the difference from Embodiment 1 is that this embodiment does not have a metering function. The loading equipment includes a buffer hopper 1 , a first gate 2 , a distributor 5 , a distributor 6 , and a dust cover 11 .

[0051] Further, the loading device also includes a distributor 5, which can spread the material along the width direction of the distributor 6, and the distributor 6 is composed of a scraper 7, a housing 8, a driving device 9 and a distribution port 10; further, the distribution The opening 10 is an elongated distribution opening (rectangular opening). Specifically, the extension direction of the elongated distribution opening and the extension direction of the scraper 7 form an included angle, and the included angle is an acute angle. The length of the discharge side of the distribution opening 10 is It matches the length of the compartment of the loading cloth openi...

Embodiment 3

[0058] see Figure 4 , the present embodiment is based on Embodiment 1 and Embodiment 2, and two distributing machines 6 are arranged side by side. This embodiment solves the defect that the loading of a wider compartment cannot be completely filled with materials in the width direction of the compartment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com