A multifunctional manual factory workshop forklift

A multi-functional, factory technology, applied in the direction of lifting devices, coatings, special surfaces, etc., can solve the problem of not being able to change the distance of the fork, etc., and achieve the effect of easy operation and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

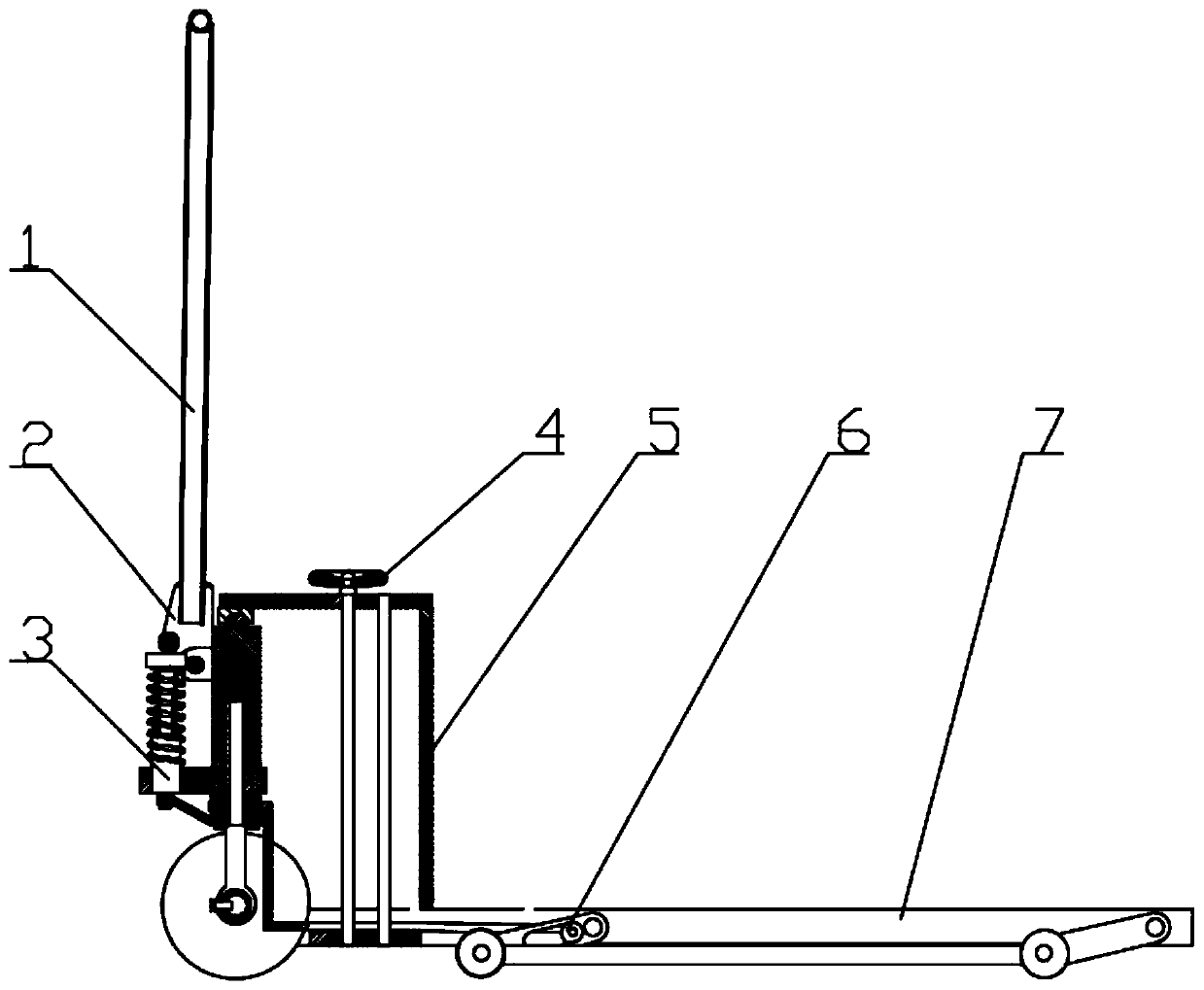

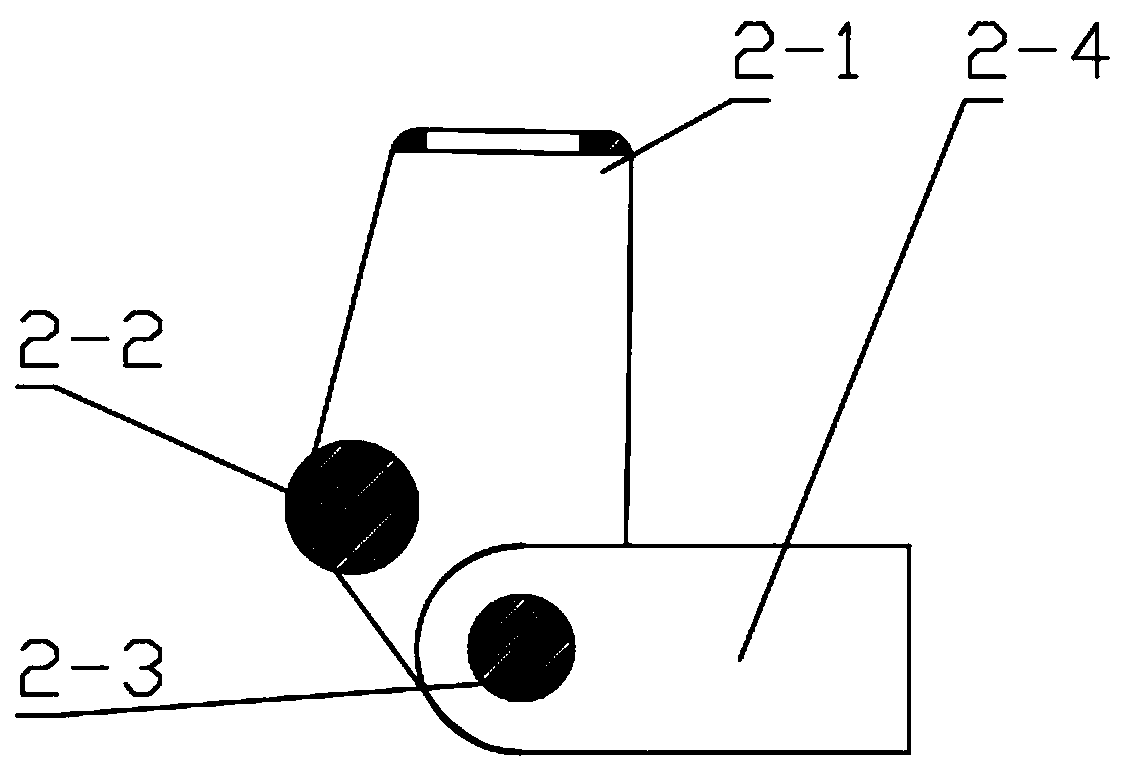

[0035] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11To illustrate this embodiment, the present invention relates to a forklift, more specifically a multifunctional manual factory workshop forklift, including a pull rod 1, a pressure frame 2, a front wheel assembly 3, a width adjustment assembly 4, a support carriage 5, Rear wheel combination 6, loading rod 7, through the simple operation of the pull rod and the hand wheel, the lifting of the forklift and the elongation and shortening of the distance between the forks can be realized. It is easy to operate, and the lifting is balanced, the rotation is flexible, and the high-strength steel structure is safe and reliable. , strong and durable, surface painting treatment, anti-corrosion.

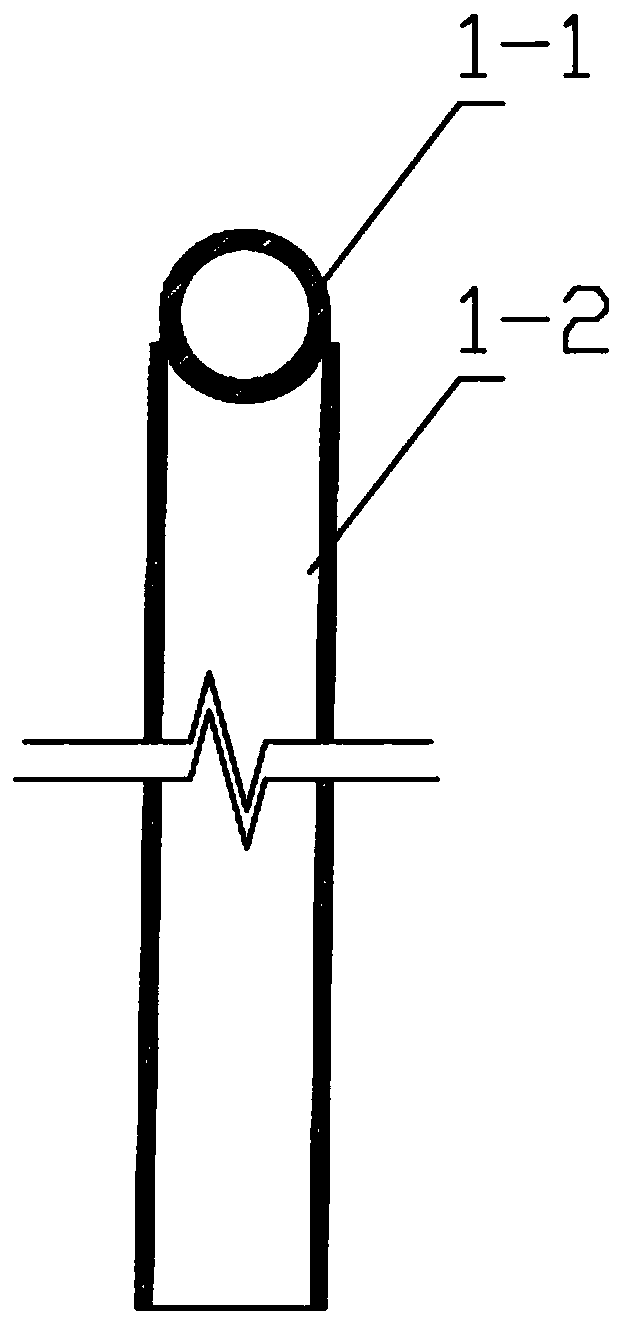

[0036] The pull rod 1 is composed of a handle 1-1 and a square tube 1-2, the handle 1-1 is installed on the upper part of the square tube ...

specific Embodiment approach 2

[0048] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 This embodiment will be described, and this embodiment will further describe the first embodiment, the surface of the pull rod 1 is painted.

specific Embodiment approach 3

[0050] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 This embodiment will be described. This embodiment will further describe Embodiment 1, and the number of the front wheels 3-6 is two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com