Line removing vehicle

A body and wheel technology, applied in the field of road construction equipment, can solve the problems of personnel nuisance, easily damaged grinding head, and vibration of the wire remover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

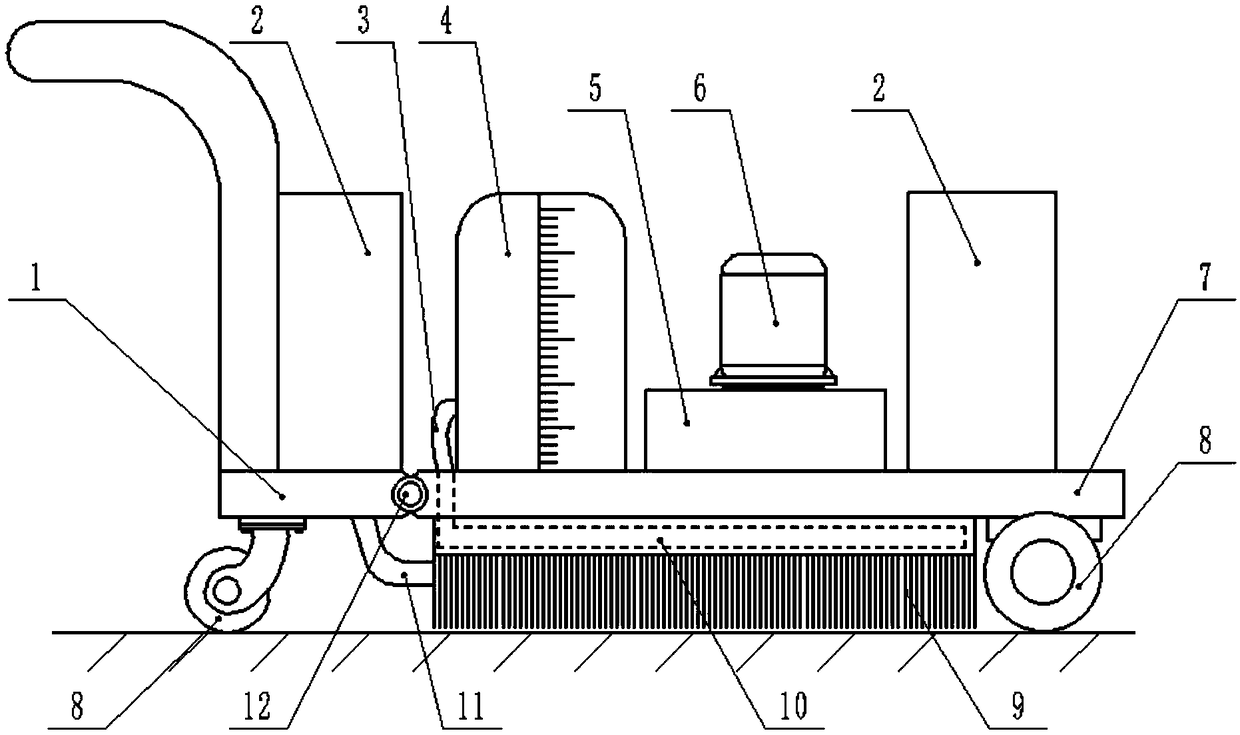

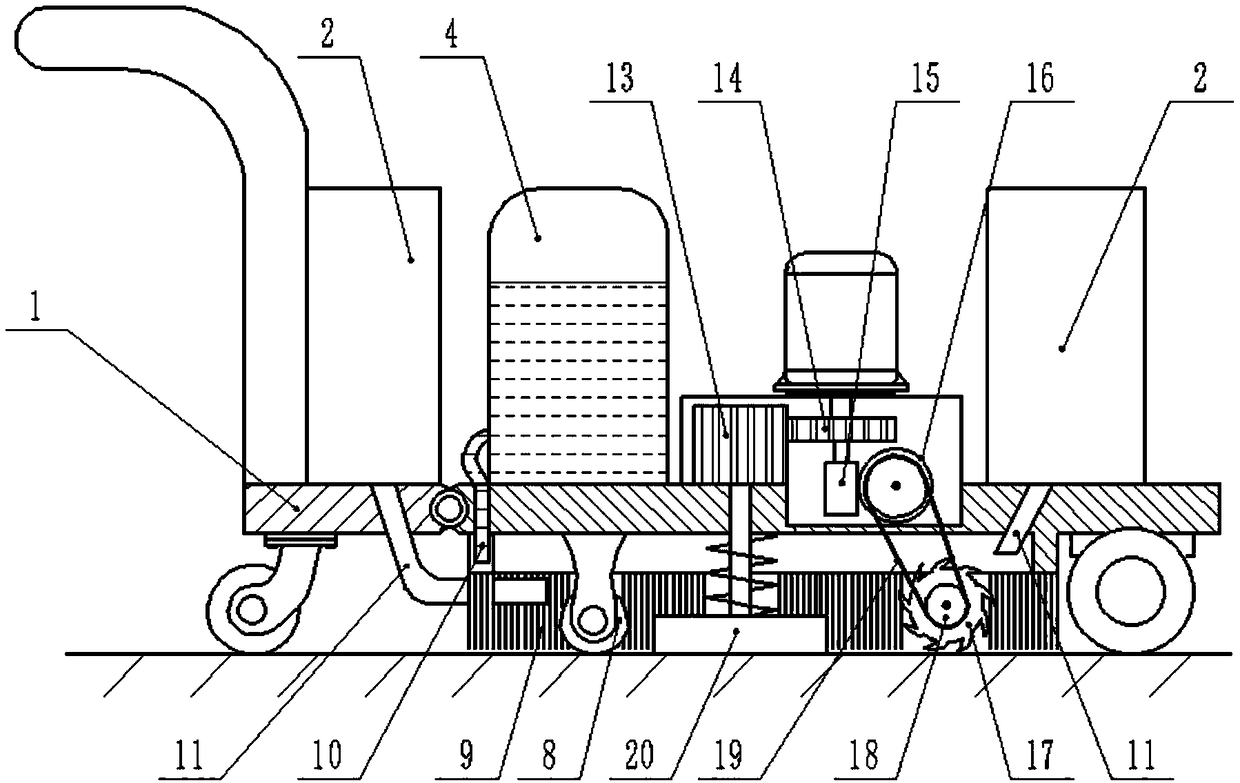

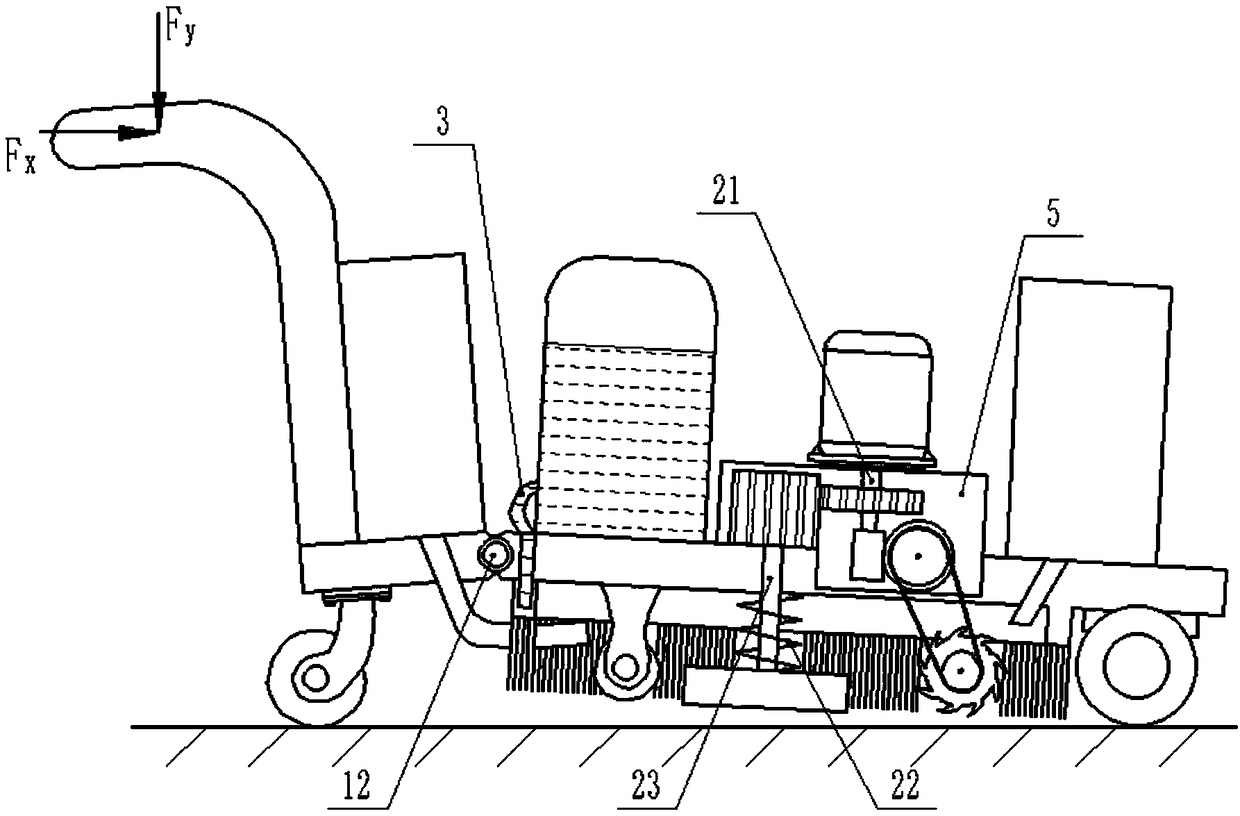

[0030] according to the above Figure 1 to Figure 6 As shown in Fig. 1, a thread removing car is produced. When the operator is using the thread removing car, when the thread removing car is not working, the operator can use force to make the body of the device arch at the hinge 12, so that the grinding device can be separated from the The ground is conducive to the promotion of the thread removal car; when the thread removal car is working, the water in the water tank 4 flows into the water tank 10 through the water outlet 3, and the water in the water tank 10 makes the dust removal top wet through the small hole 24, and the motor 6 drives the deceleration The box 5 is loaded so that the ratchet 17 and the grinding disc 20 work. The ratchet 17 ratchets backwards, and can give the wire removal car a forward force during work. The grinding disc 20 can clean up the marking lines that were not cleaned by the ratchet 17 again. Improve the efficiency of marking lines being cleaned....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com