Hydraulic engineering cast-in-place pile based on air-lift reverse circulation hole cleaning

A technology of gas lift reverse circulation and water conservancy engineering, applied in the field of cast-in-place piles in water conservancy projects, can solve the problems of inconvenient measurement of pile hole depth and sand grains, easy pollution of the working environment, easy blocking of conveying air pipes, etc., to prevent excessive air pressure Larger, increased blowing sand, increased air discharge pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

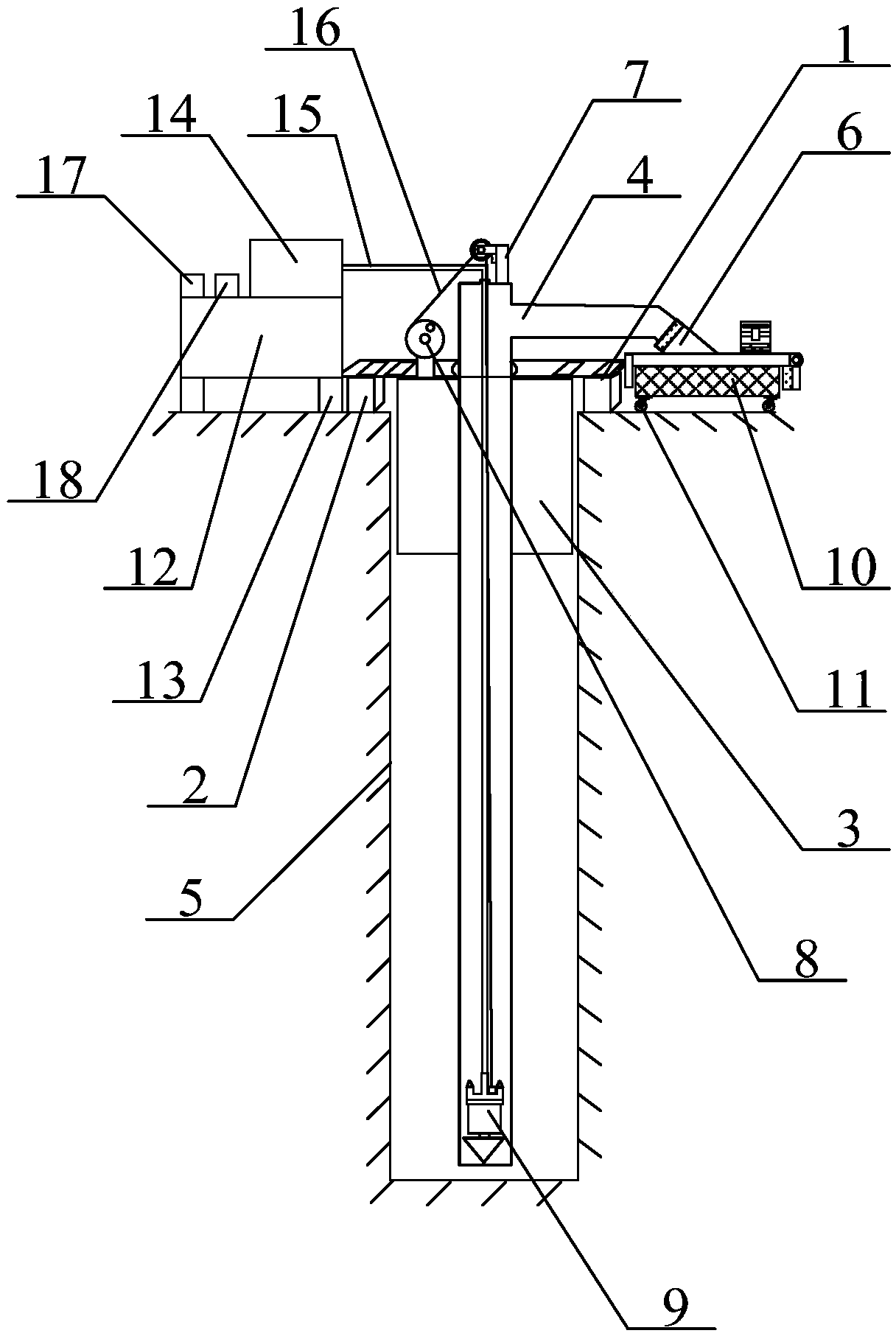

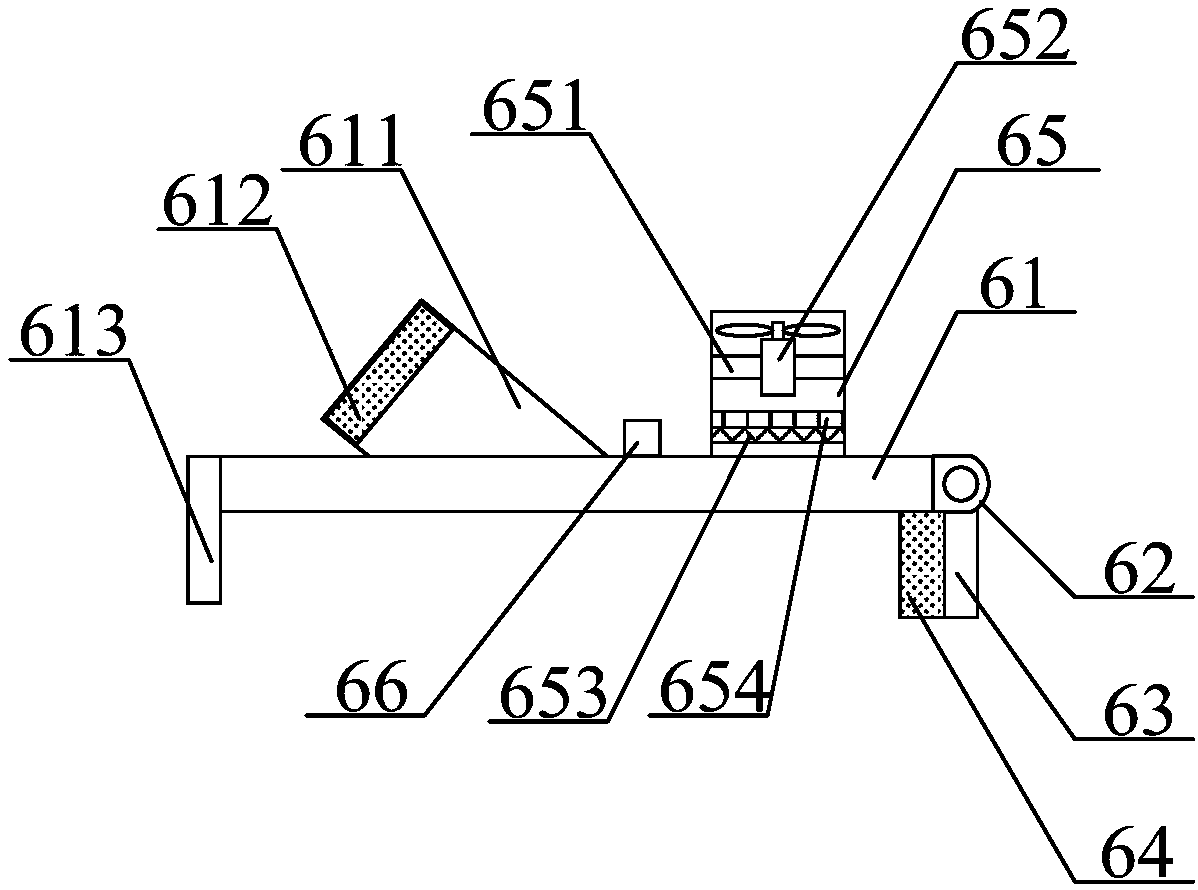

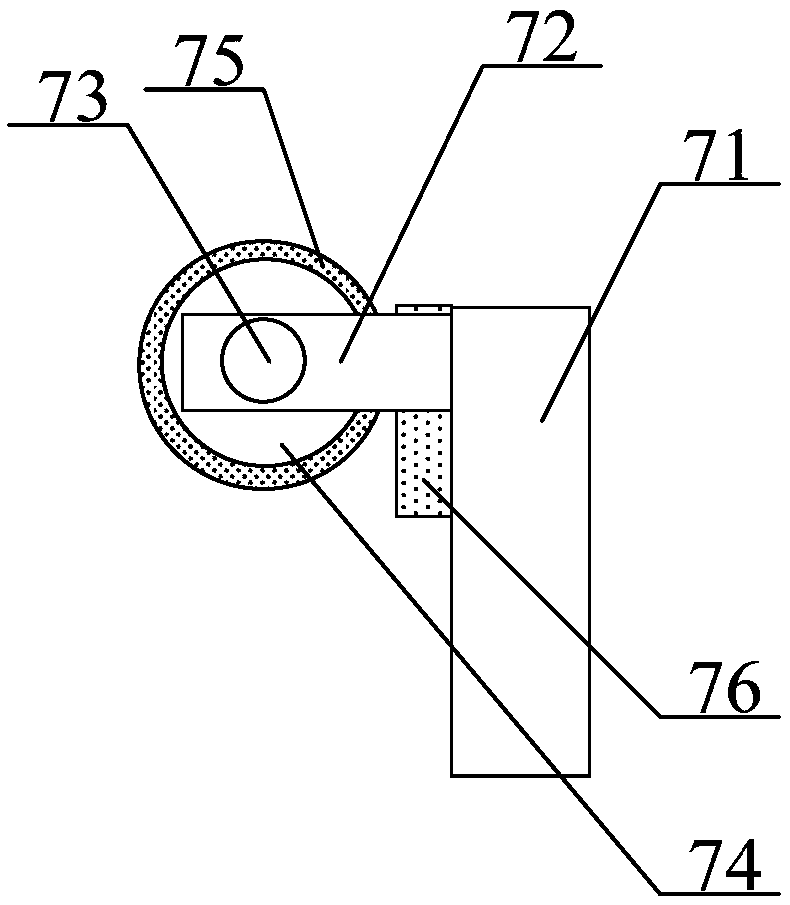

[0042] as attached figure 1 to attach Figure 5 shown

[0043] The invention provides a water conservancy project grouting pile based on gas-lift reverse circulation hole cleaning, which includes a workbench 1, a support platform 2, a steel casing 3, a conduit 4, a pile hole inner wall 5, a sand discharge and dust reduction cover structure 6, and a guide wheel protection Cover structure 7, measuring ruler winding wheel structure 8, spiral sand blowing pipe structure 9, slag receiving basket 10, moving wheel 11, fixed platform 12, outrigger 13, air compressor 14, air duct 15, software measuring ruler 16, The submersible switch 17 and the wind switch 18, the support platform 2 are respectively bolted to the left and right sides of the lower end of the workbench 1; the steel casing 3 is welded at the middle position of the lower end of the workbench 1; Respectively run through the through holes opened at the middle position inside the workbench 1; the conduit 4 also runs throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com