Prefabricated hollow beam slab construction method

A construction method and technology of hollow beams, which are applied to floors, building components, buildings, etc., can solve problems such as easy deformation of steel bars, mandrel floating phenomenon, and inability to guarantee the geometric dimensions of hollow beams and slabs, so as to improve construction progress and quality, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

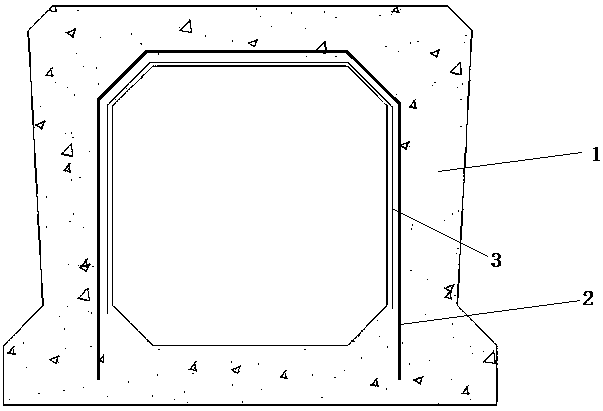

[0023] The prefabricated hollow beam slab construction method of the present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and embodiments.

[0024] A construction method of prefabricated hollow beams and slabs, which is applied to the construction of the second bid section of the Henan section of the Yellow River to Hebei Supplementary Lake Project. The prefabricated prestressed hollow beams and slabs consist of 990 pieces of prefabricated hollow beams and slabs, and all internal formwork uses inflatable cores The following is a detailed description of the steel bar installation and concrete pouring construction process. The concrete steps of this construction method are as follows:

[0025] Step 01) Formwork production: The outer formwork of the hollow beam slab is made of shaped steel formwork. Lay 6mm thick steel plate.

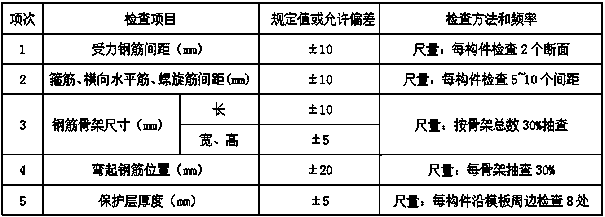

[0026] Step 02) Steel bar processing and installation:

[0027] (1) Feed material: The inco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com