Method and device for reinforcing damaged reinforced concrete column by adopting prefabricated component with sleeves

A reinforced concrete column and reinforced concrete technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of limited increase in stiffness and strength of damaged columns, low reinforcement efficiency, and large workload, and achieve good reinforcement effects. , the effect of repairing lateral stiffness and load-bearing capacity, reliable fire resistance and durability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

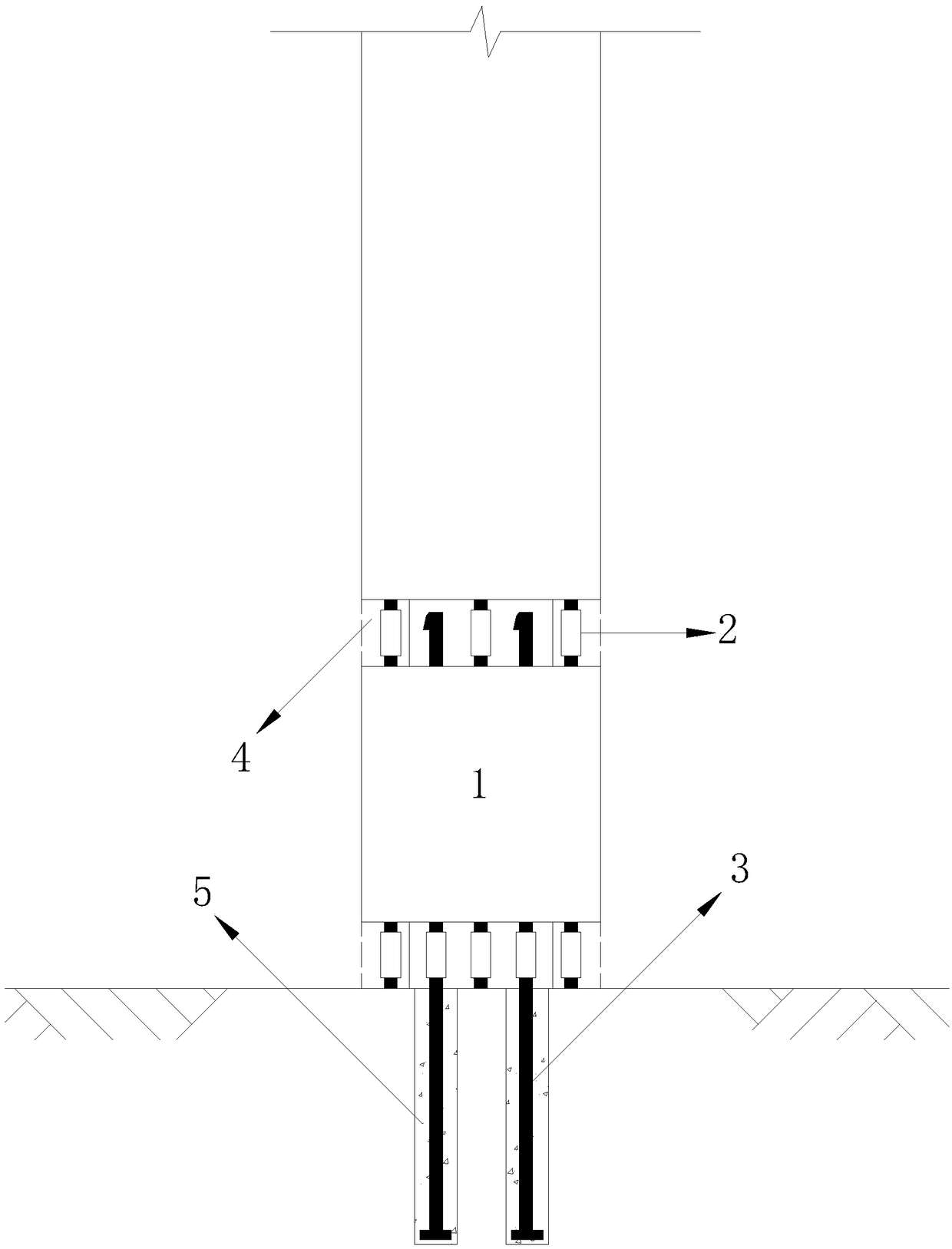

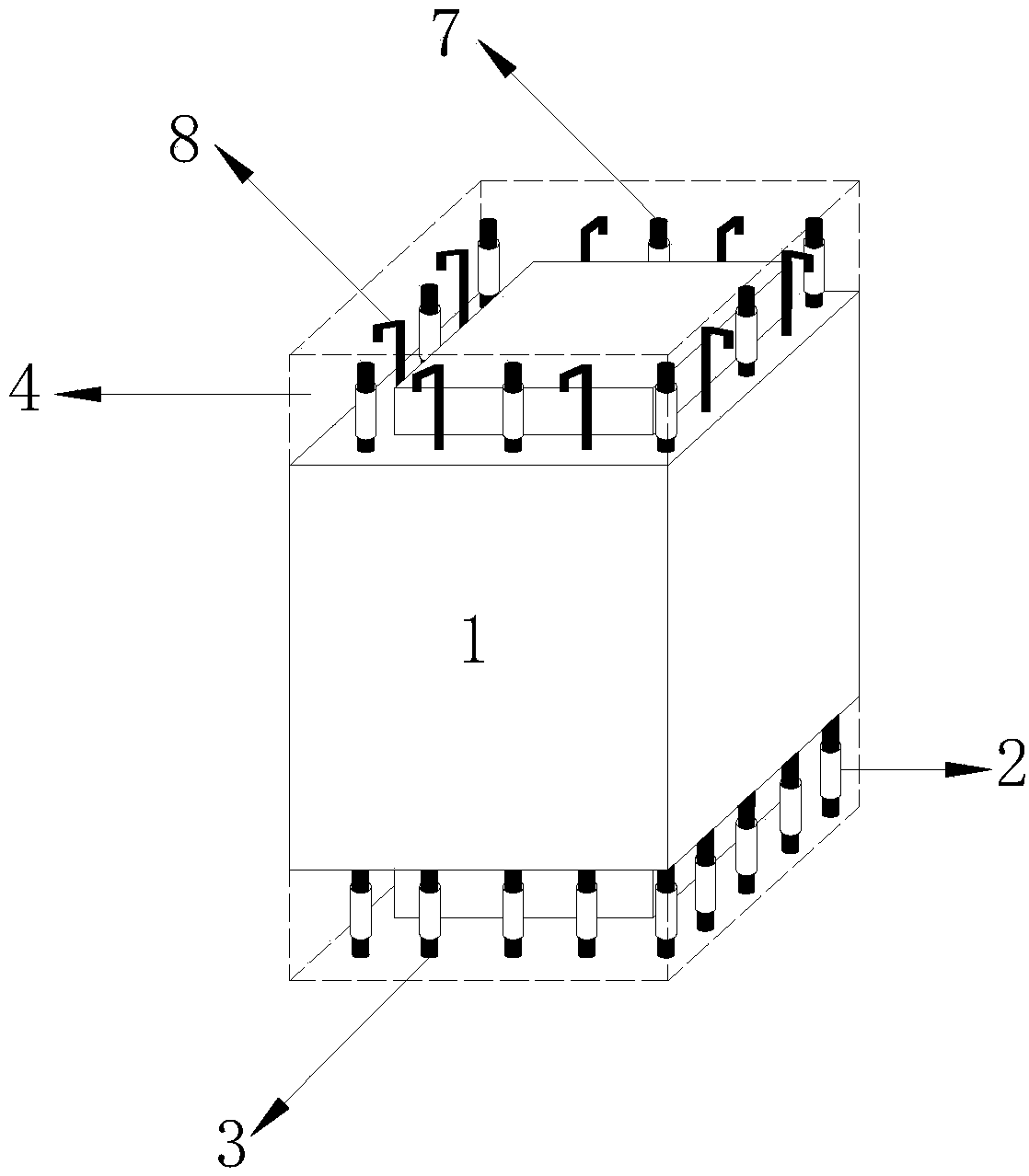

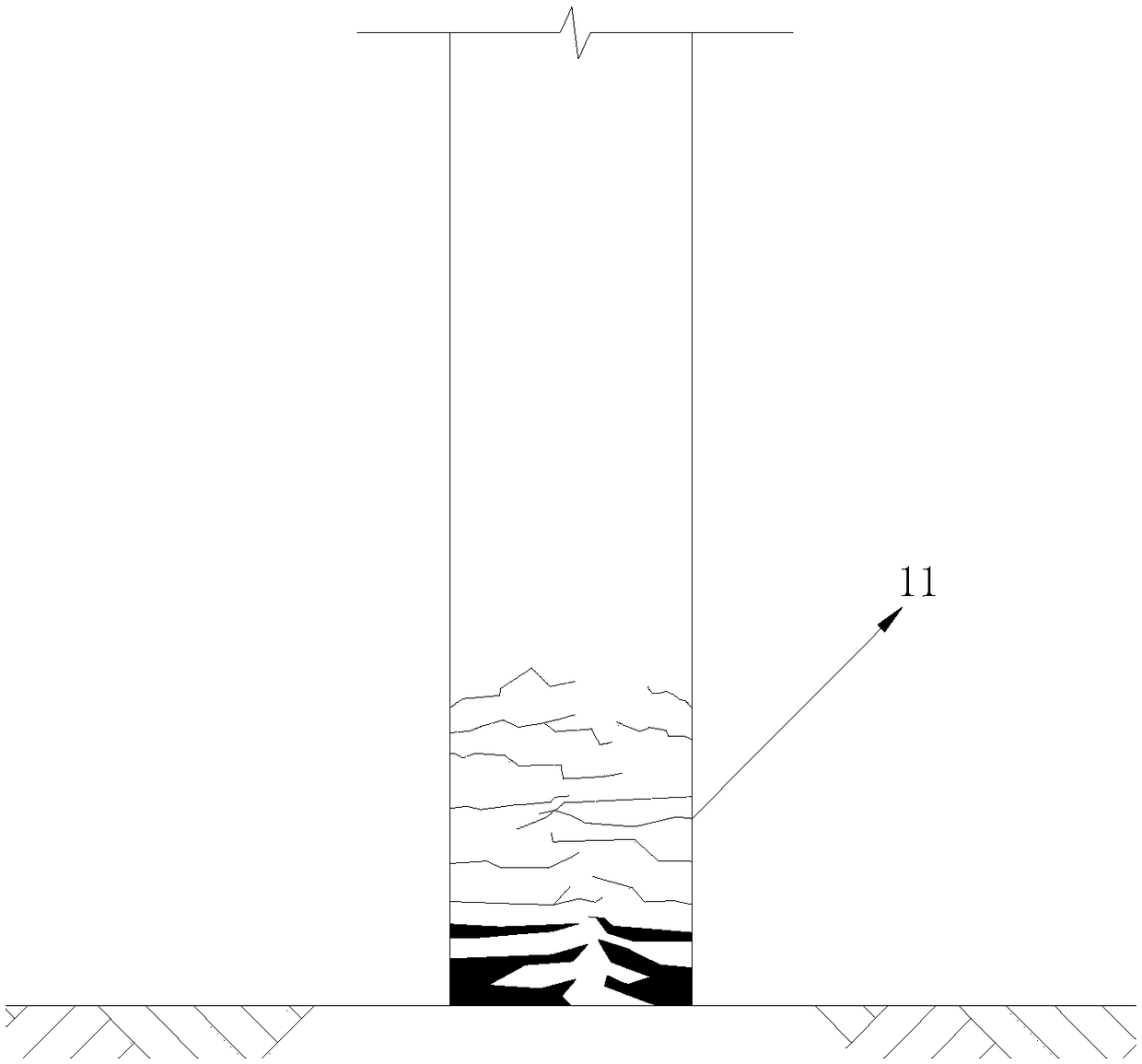

[0023] The embodiment of the strengthening method of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] The present invention proposes a method and device for quickly reinforcing the damaged column. The reinforcing device used in the method - the prefabricated parts can be prefabricated in advance in the factory, and only need to splice the prefabricated parts to the dismantled part of the damaged column end during on-site construction , so as to achieve rapid reinforcement and replacement of the damaged zone at the end of the damaged column, and effectively restore the lateral stiffness and bearing capacity of the reinforced column. The specific implementation steps are as follows:

[0025] 1) The following will introduce the prefabrication and installation construction steps of prefabricated components in detail;

[0026] 2) Except that the process of connecting the prefabricated parts with the original column requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com