Radial horizontal well drilling device and method

A horizontal well and drilling technology, applied in directional drilling, drilling equipment and methods, drilling equipment, etc., can solve the problems of limited pressure bearing, long coiled tubing length, and high operating costs, and achieve convenient construction applications and reduce construction costs. The effect of limitation and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

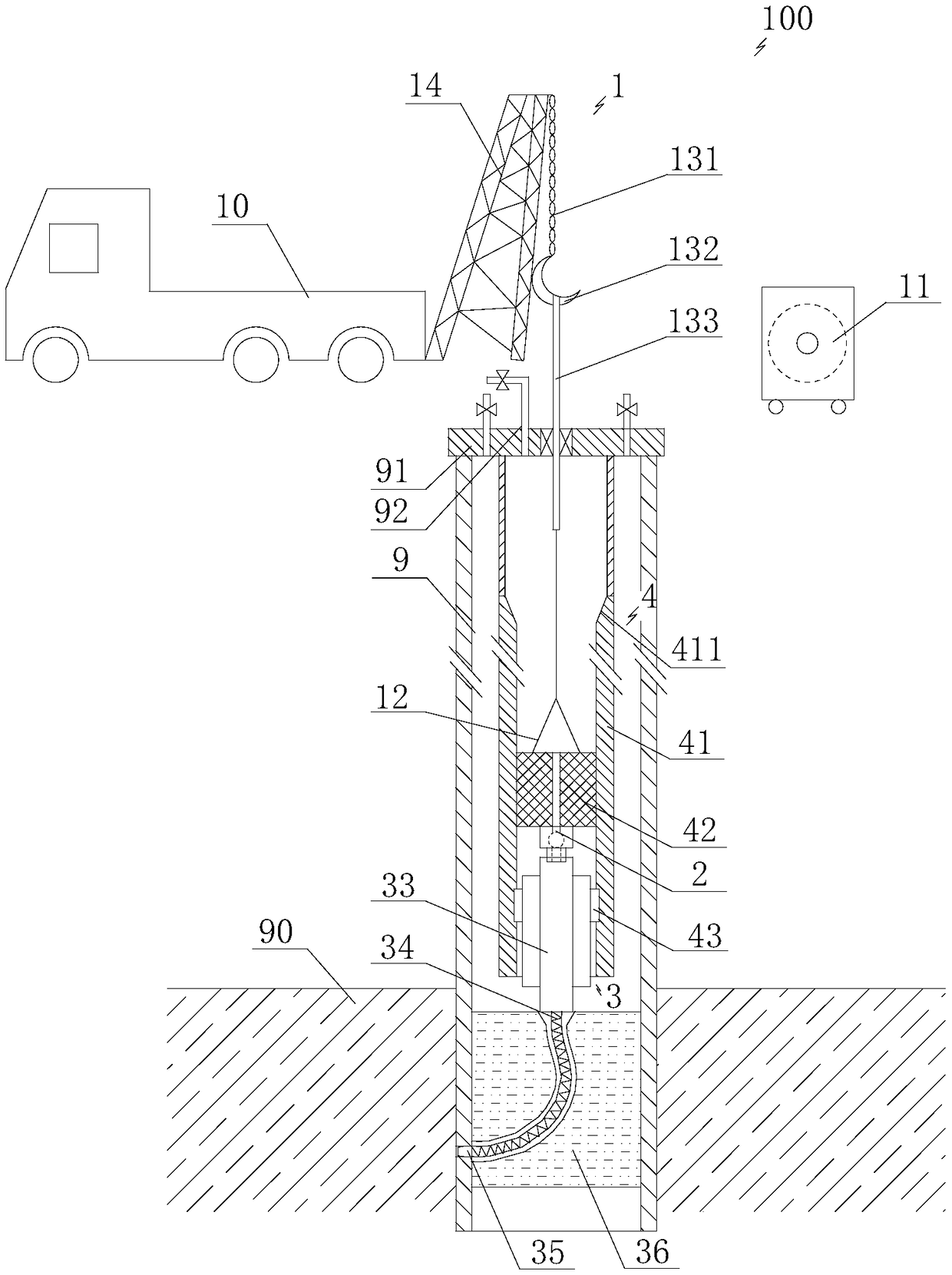

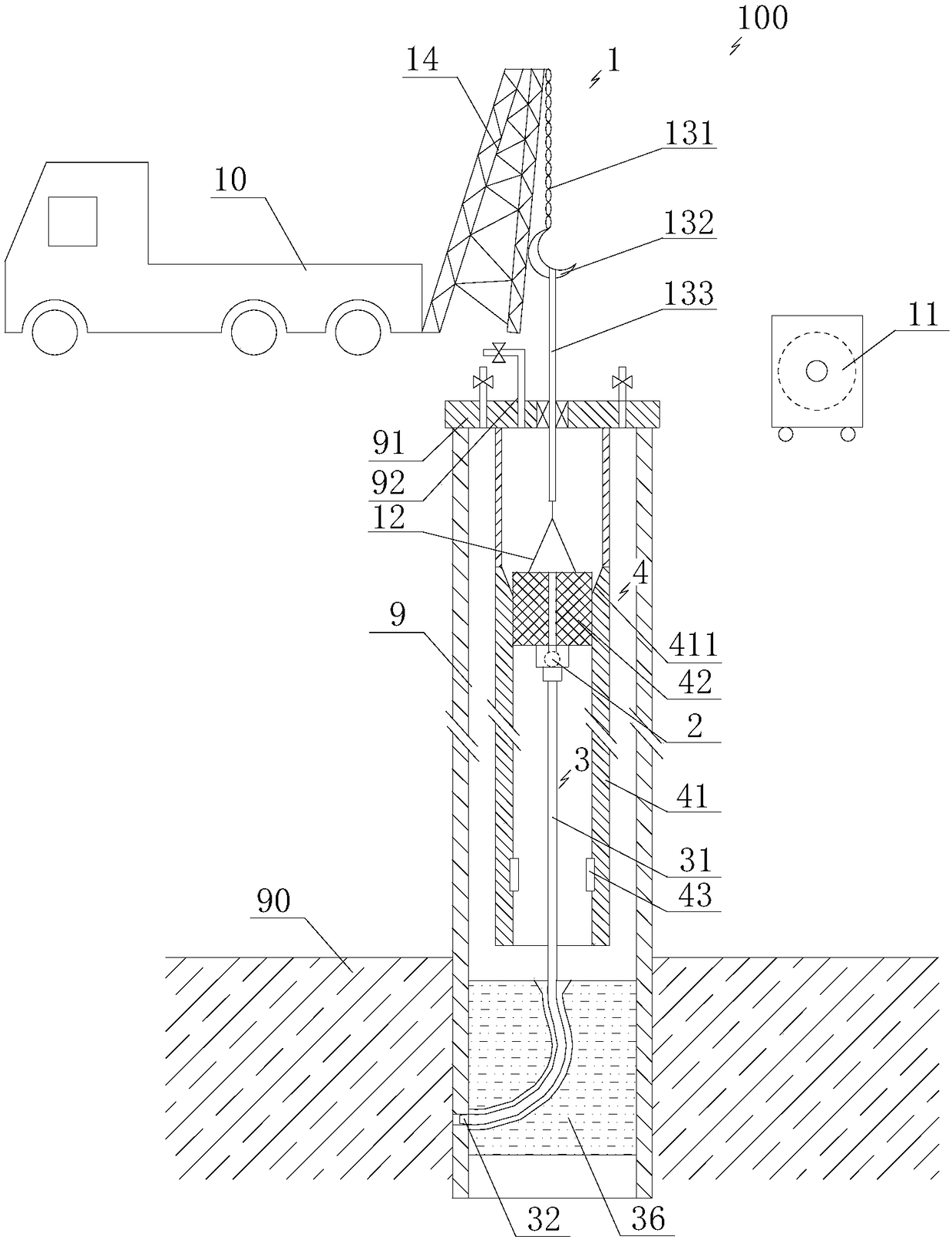

[0068] Taking the sidetracking of an old well with casing as a specific example, after many years of exploitation, the bottom hole pressure of the old well is insufficient, and problems such as overflow and well kick will not occur. After the thickened tubing 41 is run into and fixed in the well, the casing window is first opened, and the screw pump 33, the flexible shaft 34 and the drill bit 35 are connected to the bottom of the power booster part 2 on the ground and the tightness is tested to boost the power booster. Part 2 is sealed and connected to the rubber plug slider 42. The rubber plug slider 42 is hung on the steel wire rope 12. After the connection is completed, it is lowered into the well through the elevator 14. During the lowering process, pay attention to the tension of the steel wire rope 12 and monitor it at any time. The lowering situation of the device, if the lowering encounters resistance, it needs to be lowered again by the lifter 14 lifting device. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com