Deep drill hole drilling technology under high-pressure-bearing underground water condition

A groundwater, high pressure-bearing technology, applied in earthwork drilling, wellbore/well parts, sealing/isolation, etc., can solve problems such as abandonment, scrapped drilling, flooded drilling, etc., and achieve fast construction speed and high effect Good and efficient production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Overview of the test project

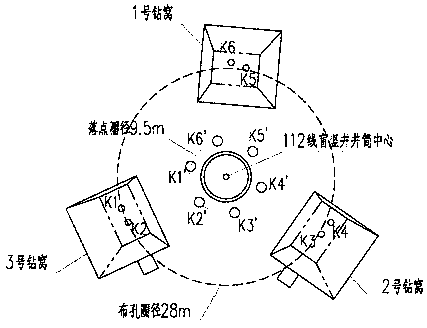

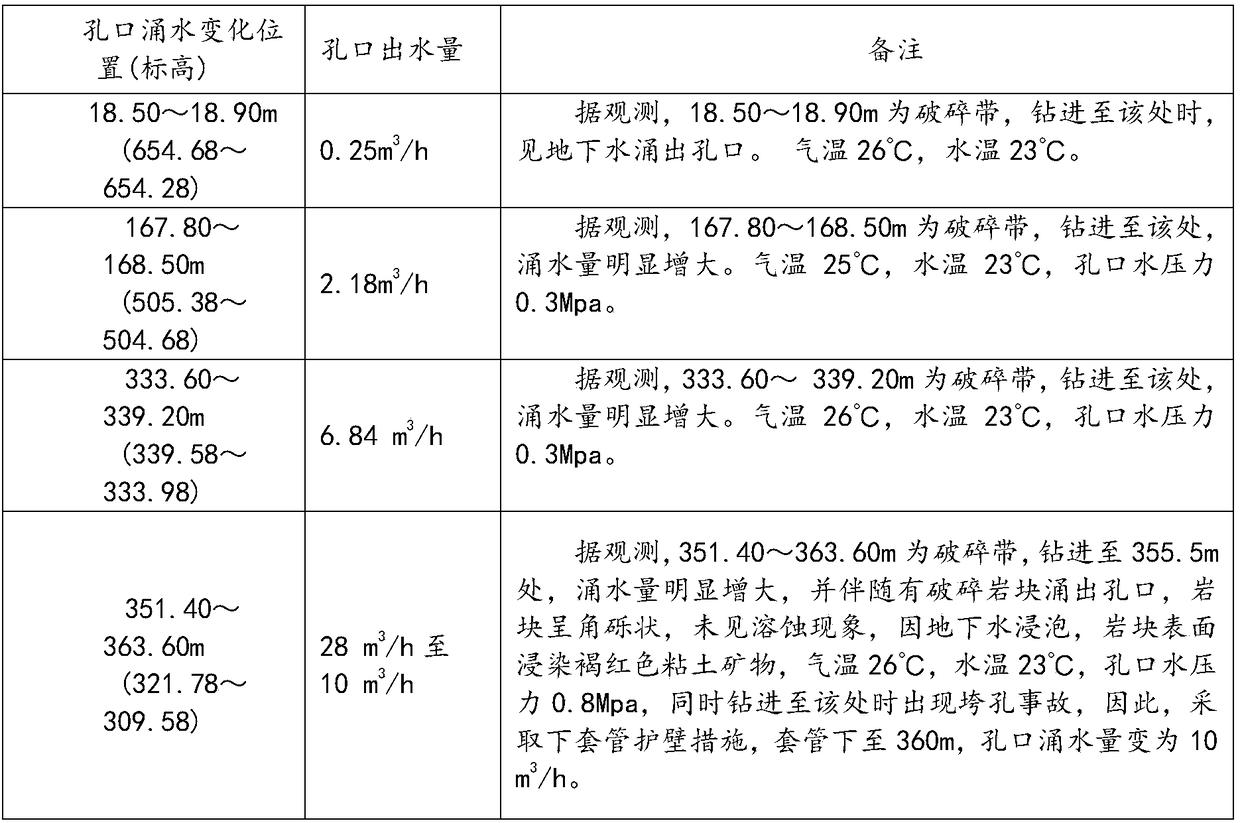

[0033] Yiliang Chihong Mining Co., Ltd. Maoping Lead-Zinc Mining Co., Ltd. has the lowest elevation of underground mineral mining in the middle section of 610 meters. It has been proven that there are still abundant mineral deposits below the middle section of 610 meters. It is a continuous replacement project for deep resources aimed at developing deep mineral deposits. It is the focus of the company's strategic development plan, and the 112-line blind shaft shaft of the supporting construction of the deep resource replacement project is the top priority of the project. The groundwater in this mining area is extremely rich, and the hydrogeological conditions are very complicated. During the drilling survey process, multiple boreholes exposed highly confined water, and water gushing accidents occurred in the boreholes.

[0034] Yiliang Chihong Mining Co., Ltd. Lead-zinc Mine Line 112 blind shaft has a net diameter of 5.7m and a barren diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com