Vertical multi-ejection-tube type three-ring fire burner

A burner and ejector technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of low power, inconvenient power adjustment, and low energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

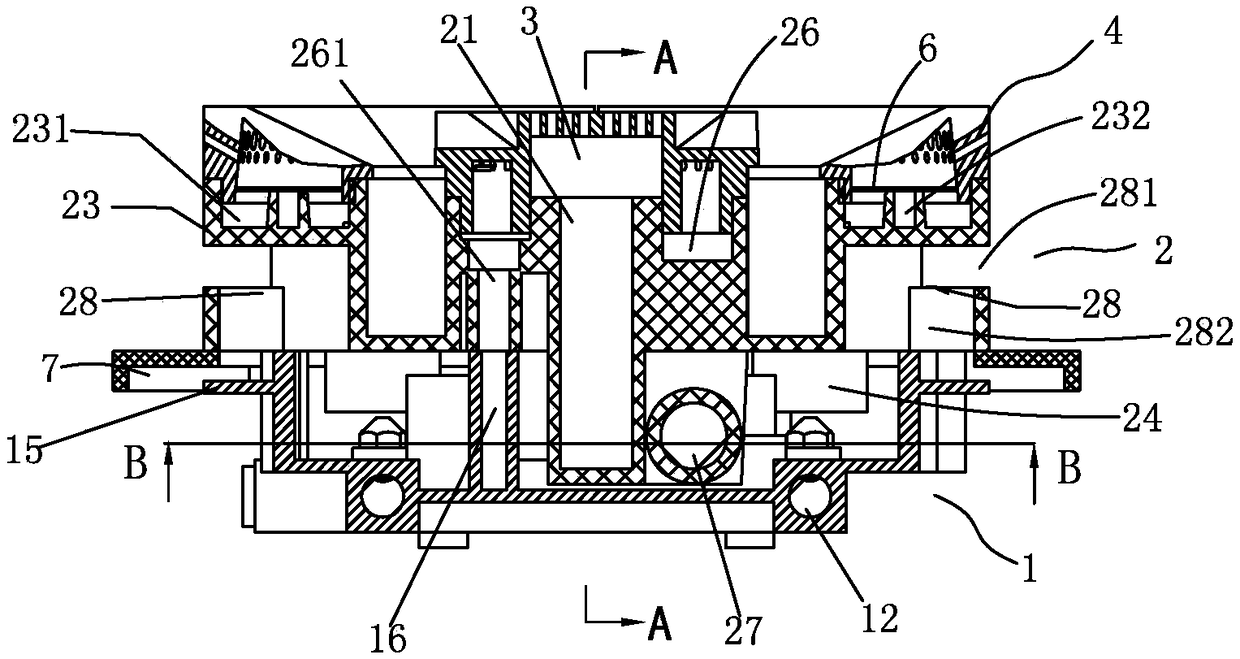

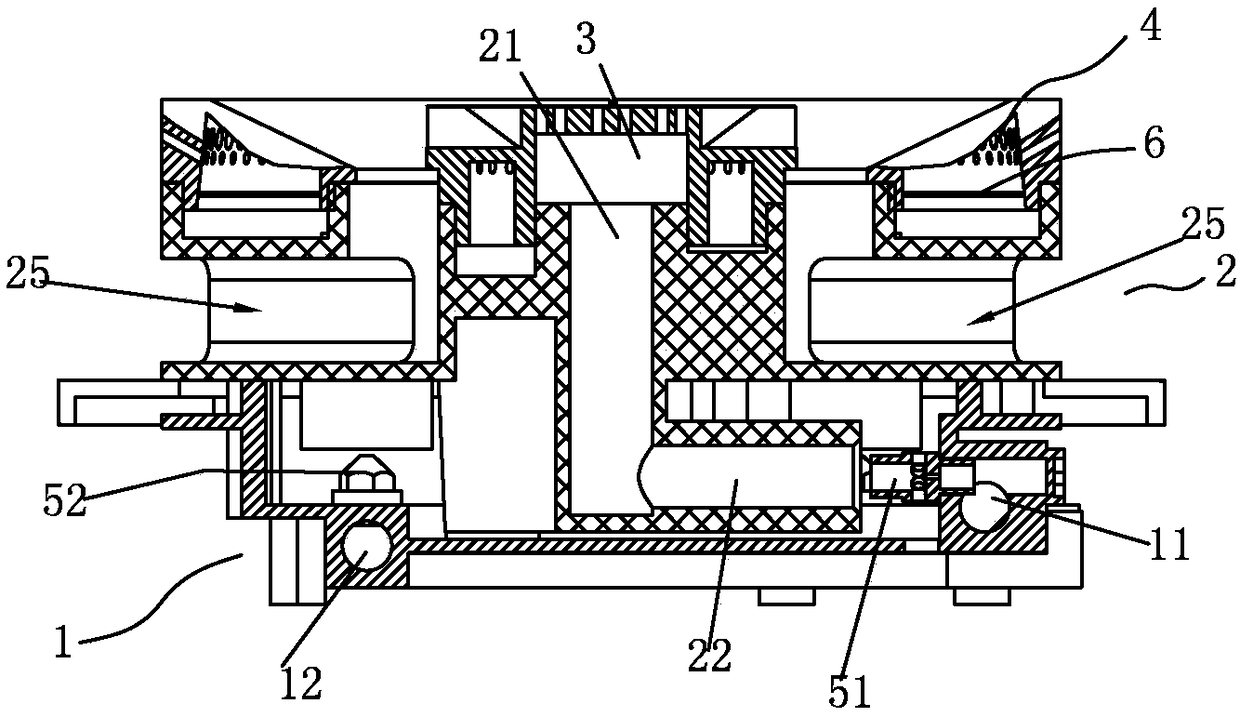

[0047] Such as figure 1 , figure 2 , image 3 As shown, a vertical multi-injection tube type three-ring fire burner includes a base 1 with an upper opening, a fire distributor seat 2, a central fire cover 3 and an outer ring fire cover 4, and the front wall of the base 1 is provided with Center air inlet 11, the outlet end of center air inlet 11 is provided with center nozzle 51, and the axis of center nozzle 51 is parallel with horizontal plane, and the base plate of base 1 is provided with the outer ring air inlet 12 of the frame of front opening, sets Some air outlet seats with the outer ring air inlet channel 12 in the base 1 are provided with an outer nozzle 52 on the air outlet seat; the fire distribution seat 2 includes a central fire cover seat 21, a center ejector pipe 22 communicated with the central fire cover seat, An annular seat 23 with an outer ring gas groove 231 , several axially outer injection pipes 24 and radial secondary air passages 25 communicated wit...

Embodiment 2

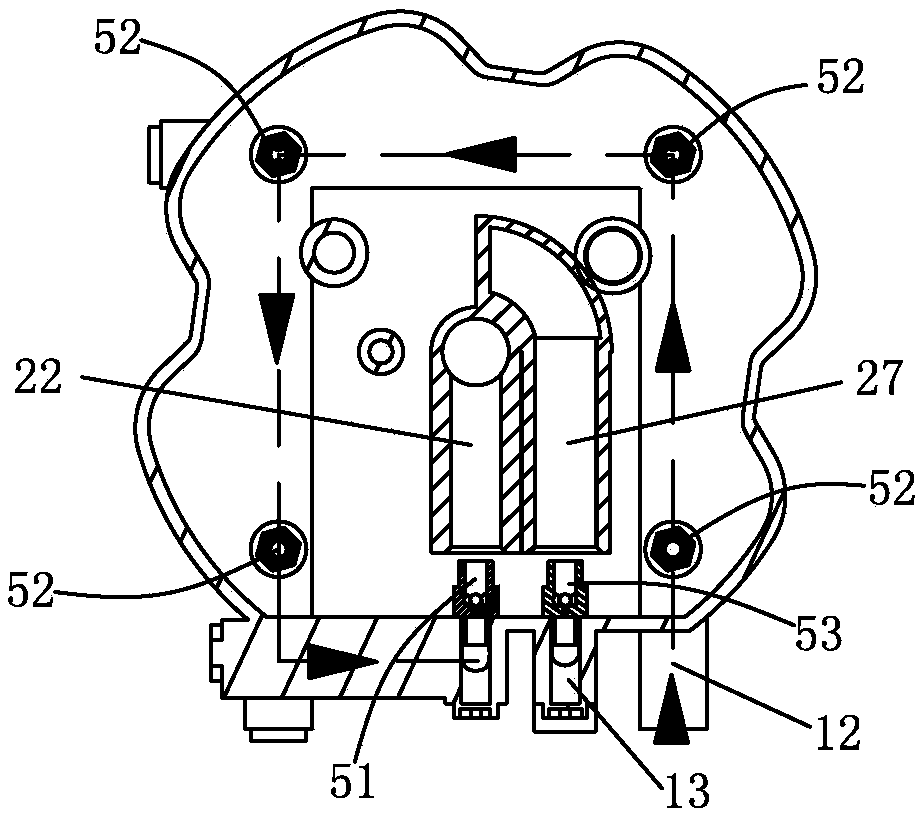

[0067] Such as Figure 8 , Figure 10 , Figure 12 , Figure 13 As shown, the axis of the inner injection pipe 27 is perpendicular to the horizontal plane;

[0068] The inner ring air inlet passage 13 extends into the base 1, and the inner nozzle 53 is arranged at the air outlet, and the axis of the inner nozzle 53 is perpendicular to the horizontal plane.

Embodiment 3

[0070] Such as Figure 14 , Figure 15 , Figure 16 As shown, the base 1 is wave-shaped, and the base 1 is provided with a wave-shaped interface 14 and a seat plate 15 surrounding the upper opening. The seat plate 15 at the trough 142 is provided with a connection hole for a liquid-receiving tray or a cooker panel connect;

[0071] The axis of the inner injection pipe 27 is parallel to the horizontal plane;

[0072] The air outlet end of the inner ring air inlet channel 13 is positioned on the inwall of the base 1, and the axis of the inner nozzle 53 at the air outlet end is parallel to the horizontal plane;

[0073] The lower end surface of the fire distributor seat 2 is provided with a counterbore 29;

[0074] The wave-shaped interface 14 is inserted into the counterbore 29; there is a gap between the lower end surface of the firearm seat 2 and the seat plate 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com