Device and method for online corrosion measurement during chemical cleaning of boiler tube

A measuring device, chemical cleaning technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve the problems of corroding boiler tubes, affecting the thermal efficiency of boilers, and being unable to accurately judge fouling and cleaning, and achieve reduction effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

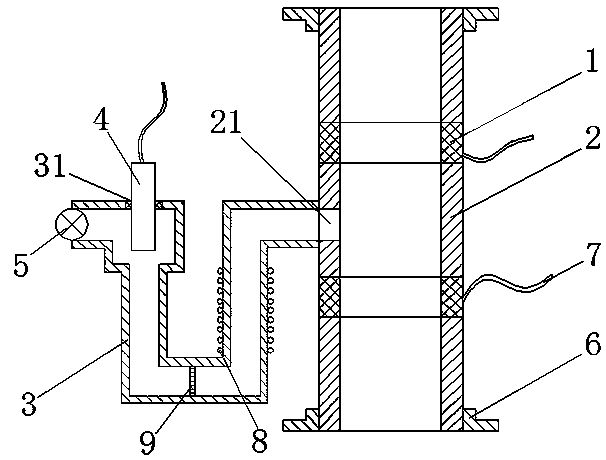

[0021] Such as figure 1 As shown, an on-line corrosion measuring device for a boiler tube chemical cleaning process of the present invention includes several insulating rings 2, at least one annular electrode 1 and a U-shaped metal tube 3. In this embodiment, the insulating ring 2 There are three, and there are two ring electrodes 1. The insulating ring 2 is made of corrosion-resistant polytetrafluoroethylene. The ring electrode is made by cutting the boiler tube to be measured. The inner diameter and outer diameter of the insulating ring 2 are the same 1, the insulating ring 2 and the ring-shaped electrode 1 are arranged at intervals, and the connection is fixed and bonded by anti-corrosion glue, and kept sealed, so that it forms a connected tubular measuring device. The inner and outer walls of the tubular measuring device are smoothly connected, and the tubular The two ends of the measuring device are fixedly provided with flanges 6, and are connected to the cut-off boiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com