Industrial process fault diagnosis method based on high order correlation

An industrial process and fault diagnosis technology, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve problems such as unbalanced fault data categories, complex industrial process systems, etc., achieve effective fault detection and identification, and is conducive to The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

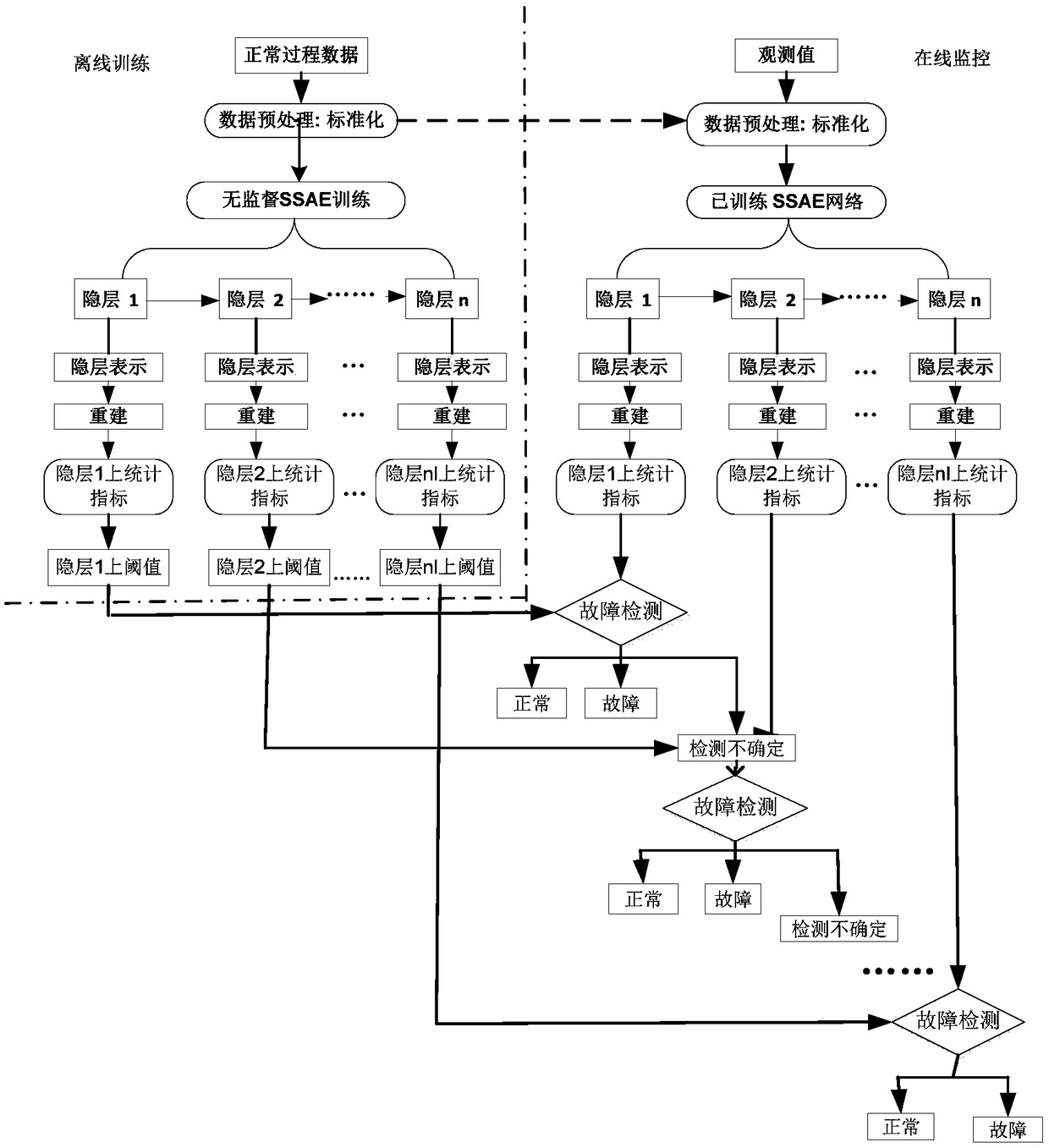

[0040] The method proposed by the present invention includes two parts of off-line modeling and on-line monitoring, and its flow chart is as follows image 3 shown.

[0041] The offline part of the method is as follows:

[0042] Step 1: Use the collection of all monitoring quantities collected under normal operating conditions in industrial processes (such as pressure values, concentration values, feed ratios, etc. in chemical processes) as the training set X train , after standardized preprocessing based on its mean and variance, we get

[0043] Step 2: Set the initialization structure parameters of the stacked sparse autoencoder network, and initialize its connection parameters randomly at the same time;

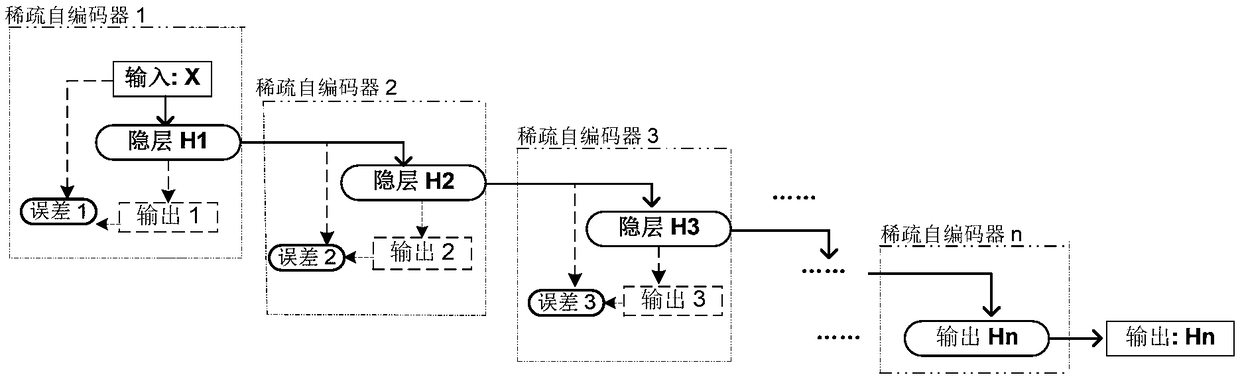

[0044] Step 3: Use layer-by-layer greedy method to train network parameters, including network structural parameters and weights, and end training until the cost function is minimized;

[0045] Step 4: The final output of the stacked autoencoder network is the high-or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com