Simulation analysis method of rotational speed compensation system for centrifugal regulator

A technology of compensation system and simulation analysis, applied in design optimization/simulation, instruments, special data processing applications, etc., can solve problems such as many factors in the normal operation of the system, performance deviation of the speed compensation system, unfavorable repairs, etc., to facilitate troubleshooting And find the point of failure, improve economic benefits, and verify the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

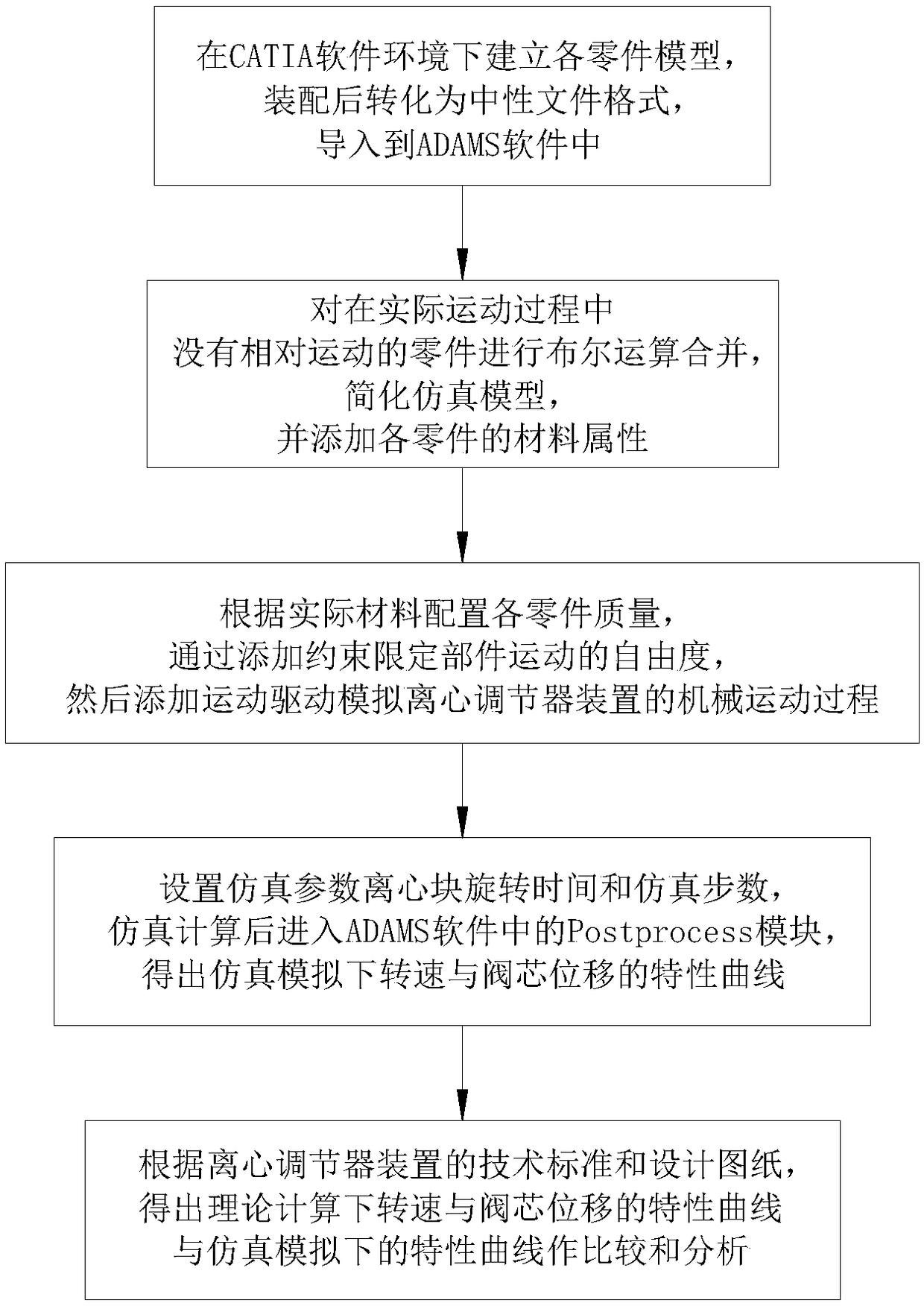

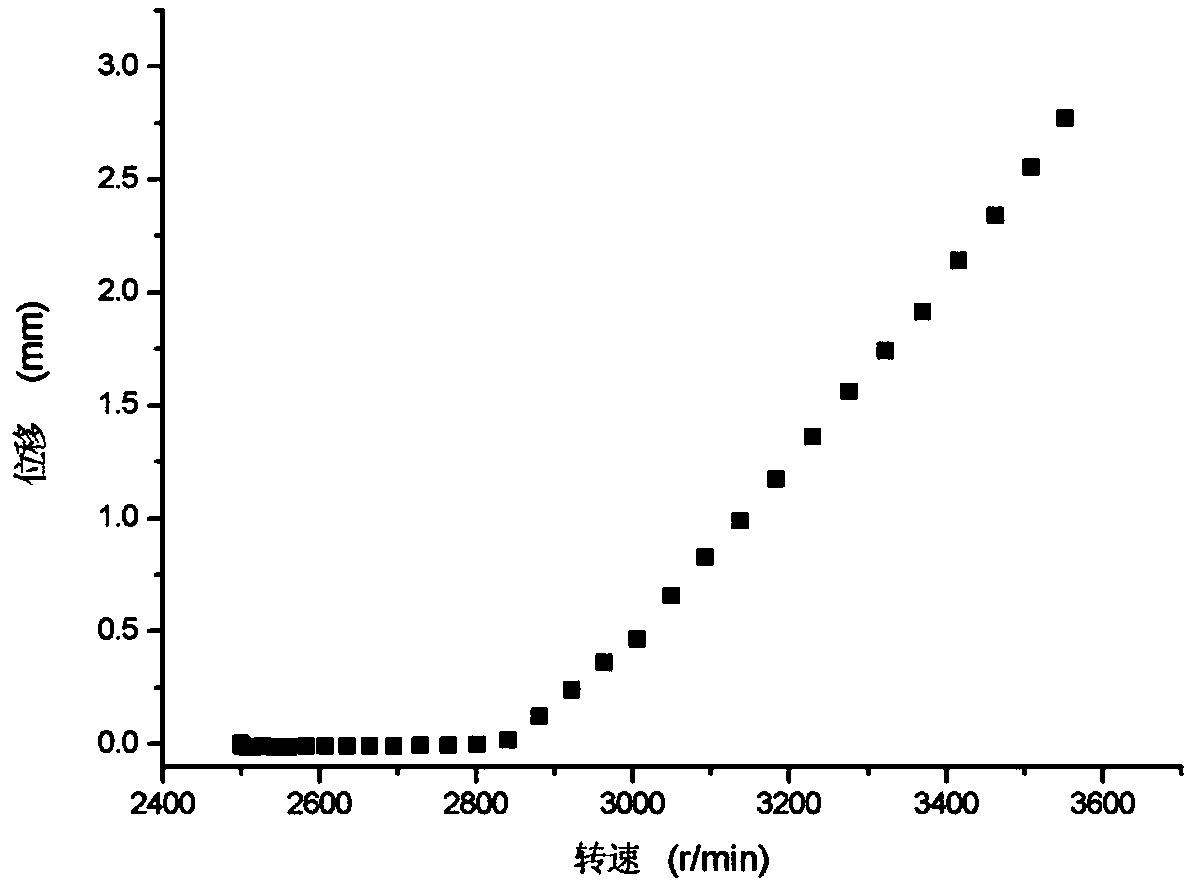

[0025] Such as Figure 1 to Figure 4 As shown, the simulation analysis method of the rotational speed compensation system of the centrifugal regulator device includes the following steps:

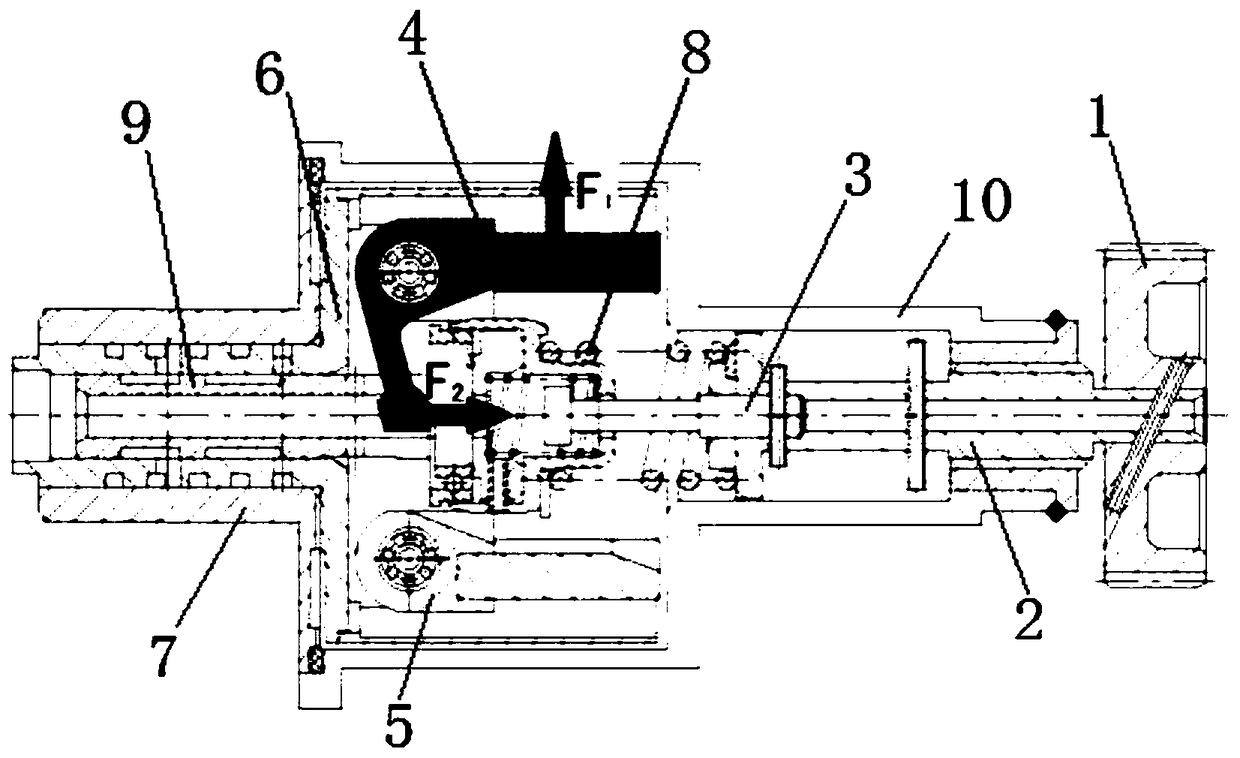

[0026] Step 1: First, use CATIA software to establish a three-dimensional model of each part of the centrifugal regulator device based on the two-dimensional drawings. The model of its main components includes turbine 1, regulating block 2, regulating rod 3, speed regulating spring 8, centrifugal block 4, centrifugal Block seat 5, rotary valve sleeve 6, valve core 9, valve sleeve 7, after creating the correct 3D model, it needs to be saved as a neutral file in "x_t" format, and then imported into the ADAMS software;

[0027] Step 2: After completing the import of ADAMS software, rename each part, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com