A heat-dissipating cable with high temperature resistance

A heat-dissipating, high-temperature-resistant technology, used in insulated cables, cables, circuits, etc., can solve the problems of complex and unpractical heat-dissipating cables, and achieve good high-temperature resistance, good heat dissipation, and stable and effective heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

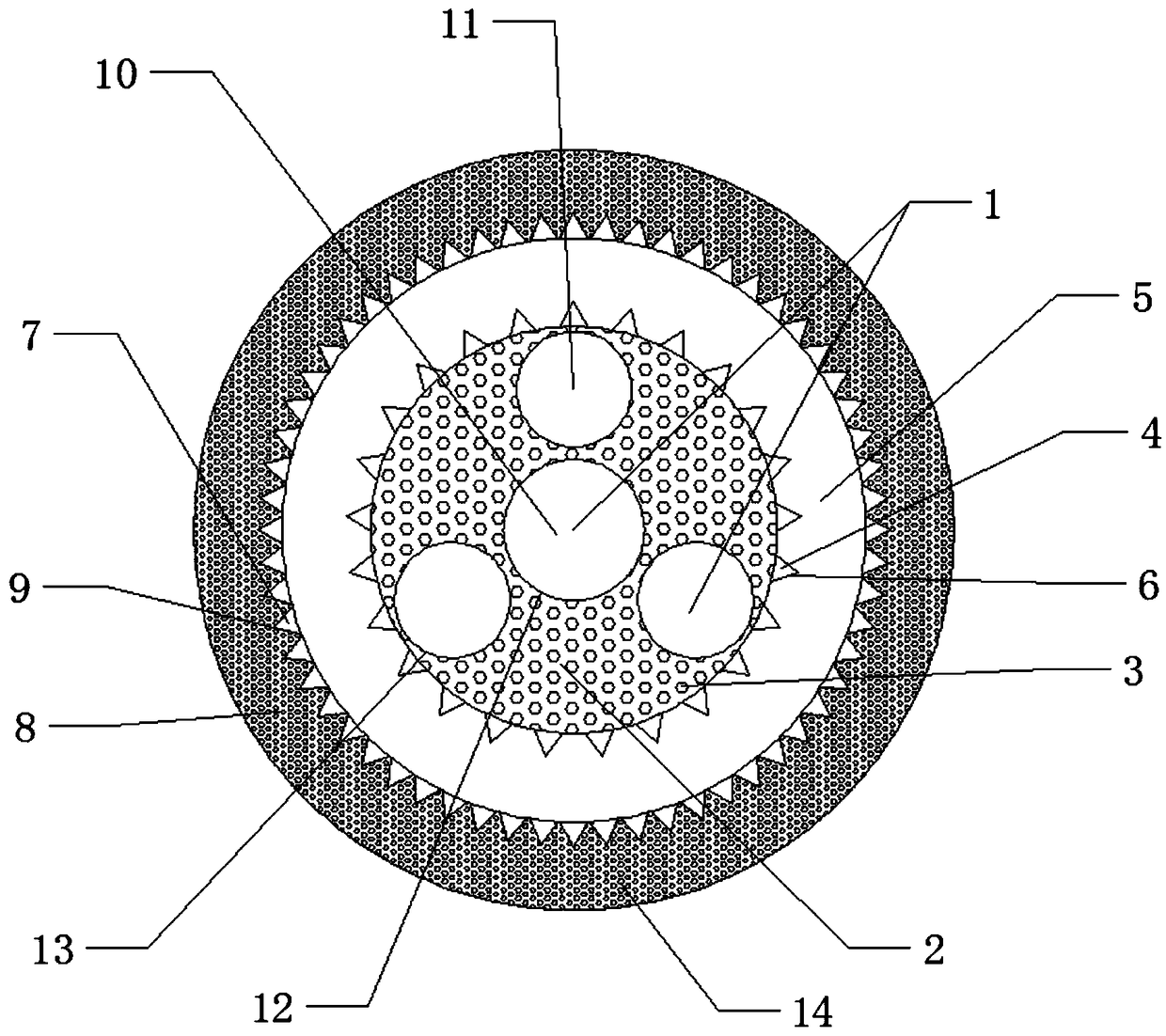

[0026] A heat-resistant heat-dissipating cable, comprising a central cable group 1 and a first heat dissipation layer 2 sheathed on the central cable group 1, the central cable group 1 is fixed inside the first heat dissipation layer 2, and the first The heat dissipation layer 2 is uniformly provided with ventilation holes 3; the outer wall of the first heat dissipation layer 2 is uniformly provided with anti-torque blocks 4, and the outer wall of the first heat dissipation layer 2 is provided with a torsion-resistant layer 5, and the torsion-resistant layer 5 Including the anti-torsion groove 6 arranged on the inner wall, the anti-torsion block 4 is placed in the anti-torsion groove 6, the anti-torsion groove 6 is uniformly arranged along the inner wall of the torsion-resistant layer 5, and the outer wall of the torsion-resistant layer 5 is arranged There is a second anti-torsion block 7, the second anti-torsion layer 8 is provided on the outer surface of the anti-torsion laye...

Embodiment 2

[0028] On the basis of Embodiment 1, the central cable group 1 includes a first cable 10, a second cable 11 uniformly distributed outside the first cable 10, and the first heat dissipation layer 2 is provided with a first cable Line card slot 12, the second cable card slot 13, the first cable 10 is placed in the first cable card slot 12, the second cable 11 is placed in the second cable card slot 13; by The first cable locking groove and the second cable locking groove matching the first cable and the second cable in the central cable group are arranged in the first heat dissipation layer, and the first cable and the second cable are respectively Placed in the first cable slot and the second cable slot, so that the central cable group is completely fixed in the first heat dissipation layer, and then through the heat dissipation of the first heat dissipation layer, the heat dissipation of the central cable group is stable and effective .

Embodiment 3

[0030] On the basis of Example 2, the second heat dissipation layer 8 is uniformly provided with second air holes 14, the diameter of the air holes 3 is larger than the diameter of the second air holes 14; the air holes are larger than the diameter of the second air holes , so that the heat dissipation effect of the cable is stronger in the middle, and gradually dissipates heat to the outside of the cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com