Lithium iron phosphate power battery and manufacturing method thereof

A lithium iron phosphate, power battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of normal temperature discharge, low specific energy, and high environmental temperature requirements, and achieve good internal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A lithium iron phosphate power battery, including a positive electrode, a negative electrode, a 25um diaphragm, a polymer gel electrolyte, and a battery case, including:

[0045] The positive electrode is composed of positive active material, binder, conductive agent and positive current collector.

[0046] The ratio is: 90wt% lithium iron phosphate is used as the positive electrode active material, 2.5wt% polyvinylidene fluoride is used as the binder; 1wt% conductive carbon black is used as the conductive agent; 16um aluminum foil is used as the positive electrode current collector;

[0047] The negative electrode is composed of negative electrode material, conductive agent, thickener, binder and negative electrode collector.

[0048] The ratio is: the negative electrode material uses 91wt% graphene; the conductive agent uses 0.2wt% conductive carbon black; the thickener uses 0.5wt% sodium carboxymethyl cellulose; the binder uses 2wt% styrene-butadiene rubber; The neg...

Embodiment 2 to 5

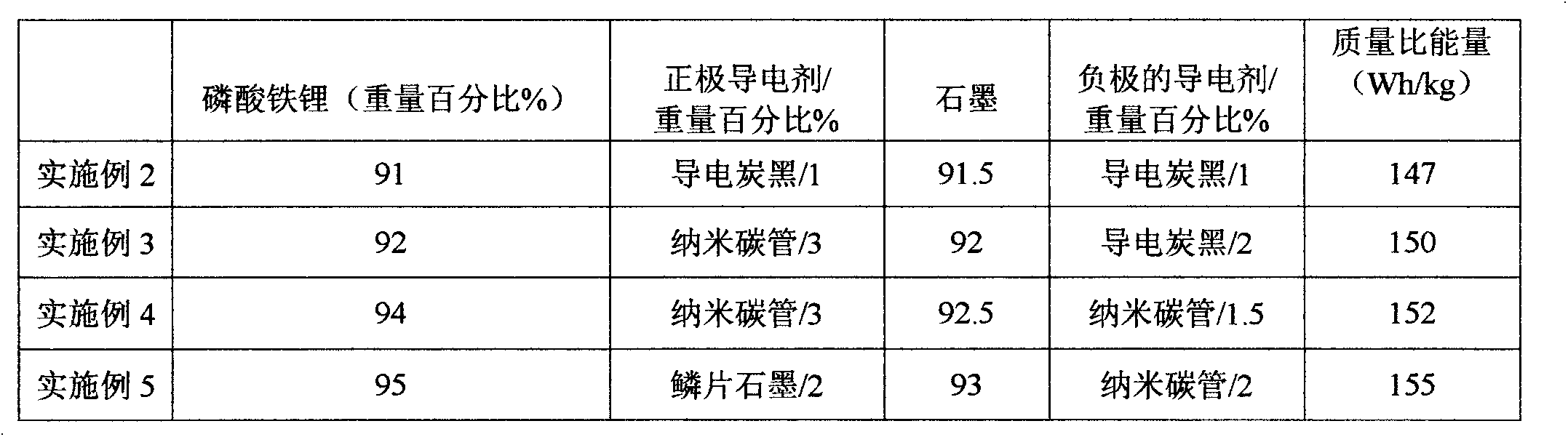

[0064] Most of the manufacturing process is the same as in Example 1, the difference is that the content of lithium manganate, lithium nickel cobalt manganese oxide, the selection and content of positive electrode conductive agent, the selection and content of graphite and the selection and content of negative electrode conductive agent The characteristics of the obtained lithium iron phosphate power battery are shown in Table 1 below.

[0065] Table I

[0066]

[0067] The positive electrode material is mainly lithium iron phosphate, and one or more substances such as conductive graphite, flake graphite, and carbon nanotubes are added, and the negative electrode active material is one or more of artificial graphite, natural graphite, mesocarbon microspheres, or hard carbon materials. Various, the conductive agent adopts one or more of conductive carbon black and carbon nanotubes; to improve the specific energy and structural stability of the soft-packed winding lithium iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com