Milling cutter disc for milling cutter

A technology for milling cutter discs and milling cutters, which is applied to milling cutters, milling machine equipment, clamping, etc., can solve the problems of inconvenient installation and disassembly of milling cutters, low stability performance, and influence on machining accuracy, so as to achieve convenient and fast installation and disassembly, Good stability and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

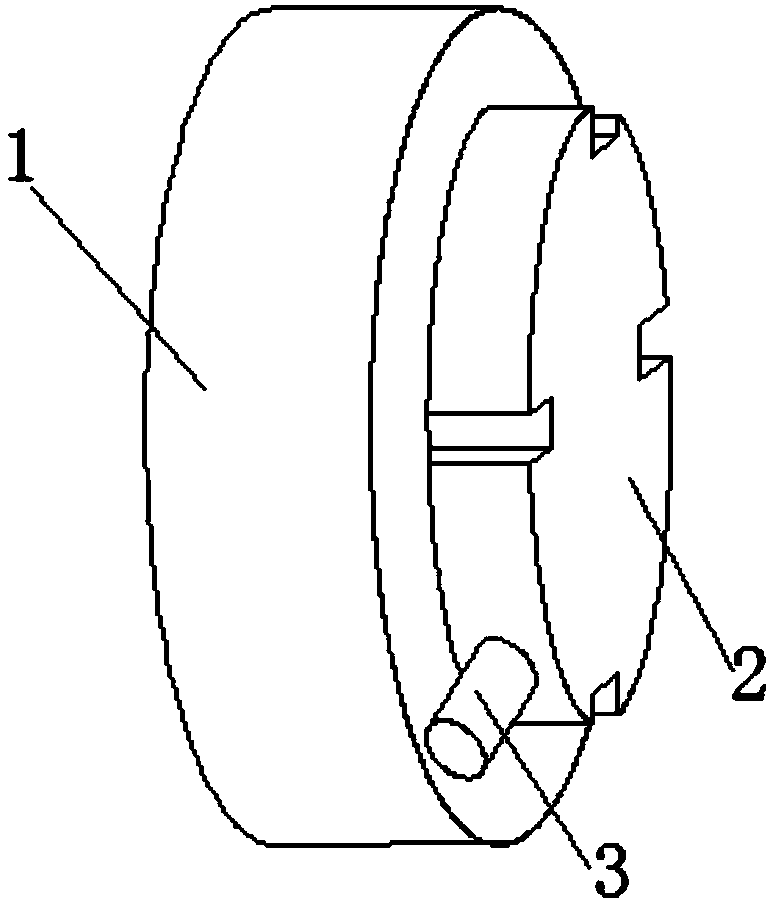

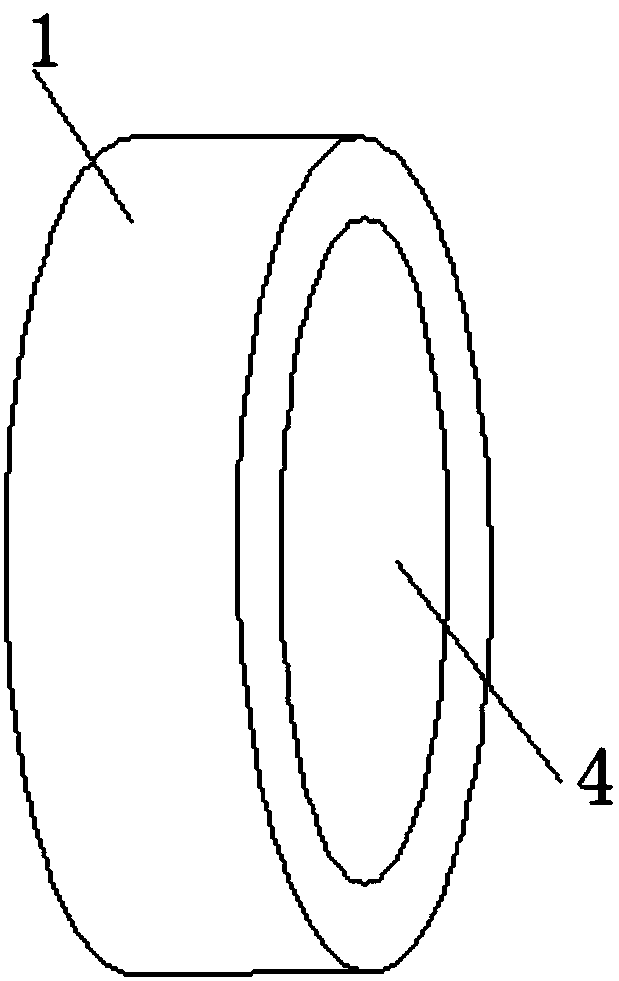

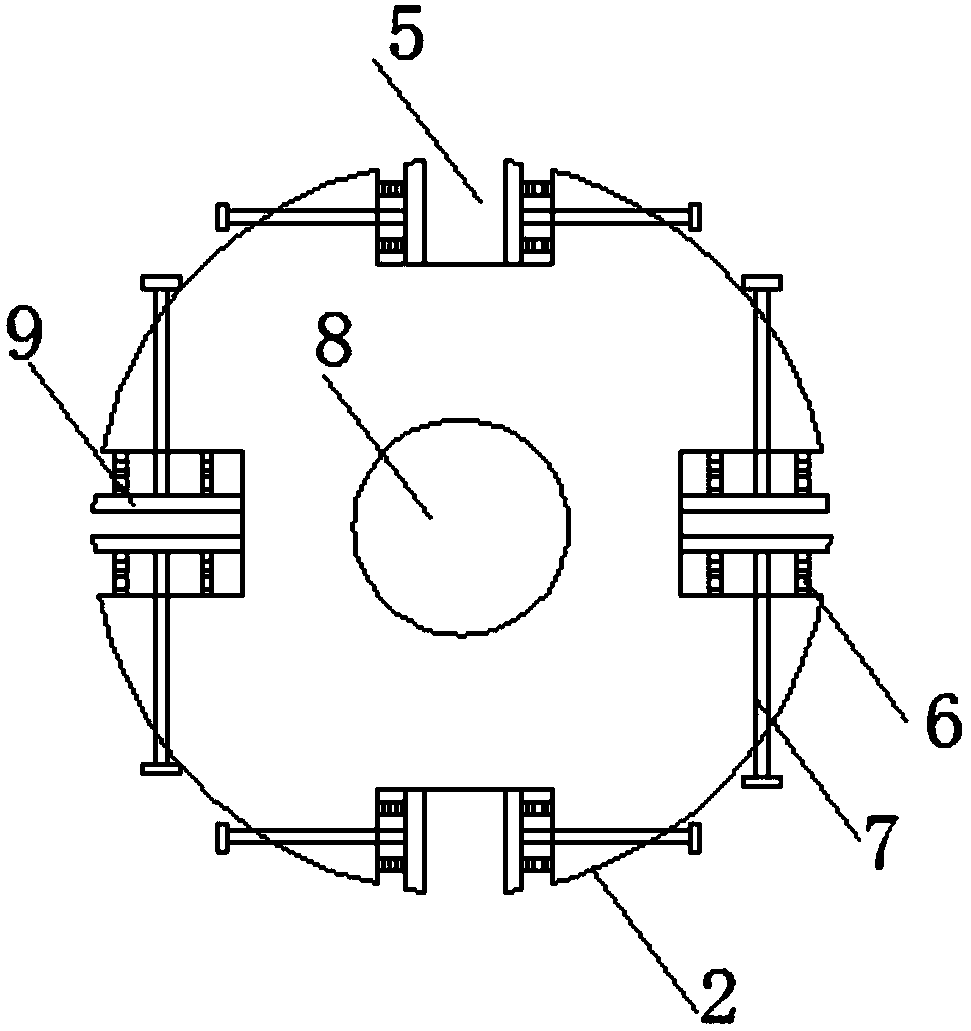

[0021] see Figure 1-4 As shown, a milling cutter disc for a milling cutter includes a fixing plate 1, a mounting plate 2 and a slot 5, one end of the fixing plate 1 is connected with a mounting plate 2, and the mounting plate 2 is connected to the fixing plate 1 through a screw rod 8, and the mounting plate is in operation 2 is installed on one end of the fixed plate 1 through the screw 8 and the screw hole 4, so that the installed plate 2 can be freely disassembled from the side of the fixed plate 1. 2 There are four groups of card slots 5 evenly arranged inside, and push plates 9 are connected to both sides of the card slots 5, and several damping springs 6 are evenly installed on one side of the push plate 9 and the inner side of the card slots 5, to be used during work The milling cutter is clamped inside the draw-in groove 5, and the shock-absorbing spring 6 promotes the tight connection between the push plate 9 and the outer two sides of the milling cutter. The milling ...

Embodiment 2

[0023] Additionally, according to Figure 1-4 As shown, the difference between it and the above-mentioned embodiment is that: one side of the mounting plate 2 is connected with a connecting pipe 3, and the connecting pipe 3 is connected to several perforations 10 through an internal pipe. The liquid flows out from the perforation 10 to reduce the temperature of the milling cutter inside the slot 5 and remove debris outside the milling cutter, which is beneficial to improving the working efficiency of the milling cutter. The middle end of the fixing plate 1 is provided with a screw hole 4, and the mounting plate 2 is movably connected with the fixing plate 1 through the screw rod 8 and the screw hole 4. Maintenance is simple. Both sides of the slot 5 are connected with fastening bolts 7, and one end of the fastening bolts 7 runs through the fixed plate 1 to connect to the push plate 9, the milling cutter is clamped inside the slot 5, and the fastening bolt 7 can be turned to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com