A control method of a power battery thermal management system

A thermal management system and power battery technology, applied in battery temperature control, secondary batteries, circuits, etc., can solve problems such as energy waste, affecting battery operating efficiency and life, thermal management system operation lags behind power battery temperature changes, etc., to achieve ensure high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

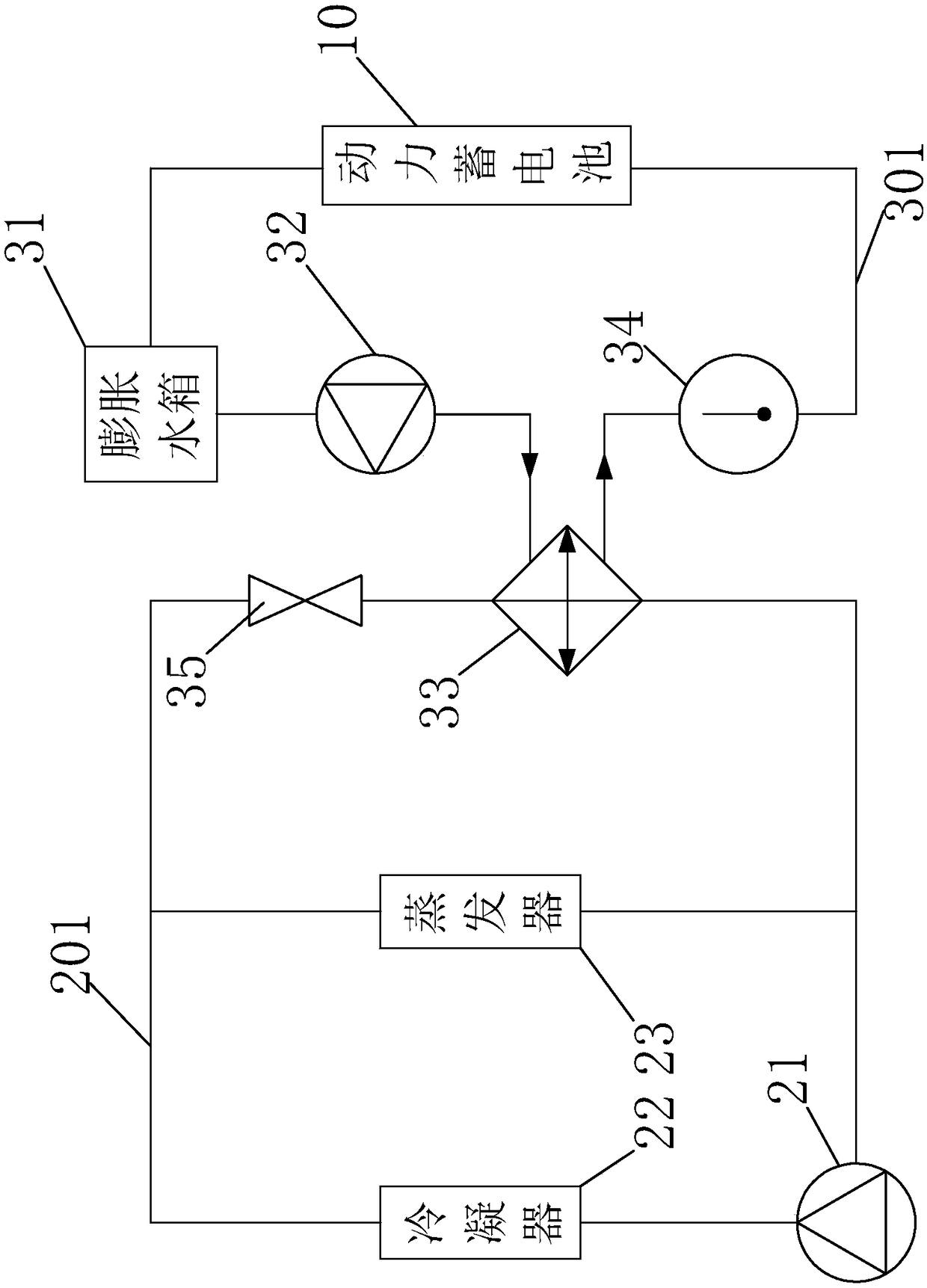

[0039] refer to figure 1 , a power battery thermal management system, including a heat exchanger 33, a water pump 32, an expansion tank 31, a power battery 10, a heater 34, a solenoid valve 35, a compressor 21, a condenser 22 and an evaporator 23, the heat exchange The device 33 includes a first passage and a second passage. The compressor 21, the condenser 22, the evaporator 23, the solenoid valve 35 and the first passage are connected through a refrigerant pipeline 201 to form a refrigerant circulation loop. The expansion tank 31, the water pump 32 , the second channel, the heater 34 and the traction battery 10 are connected through the coolant pipeline 301 to form a coolant circulation loop.

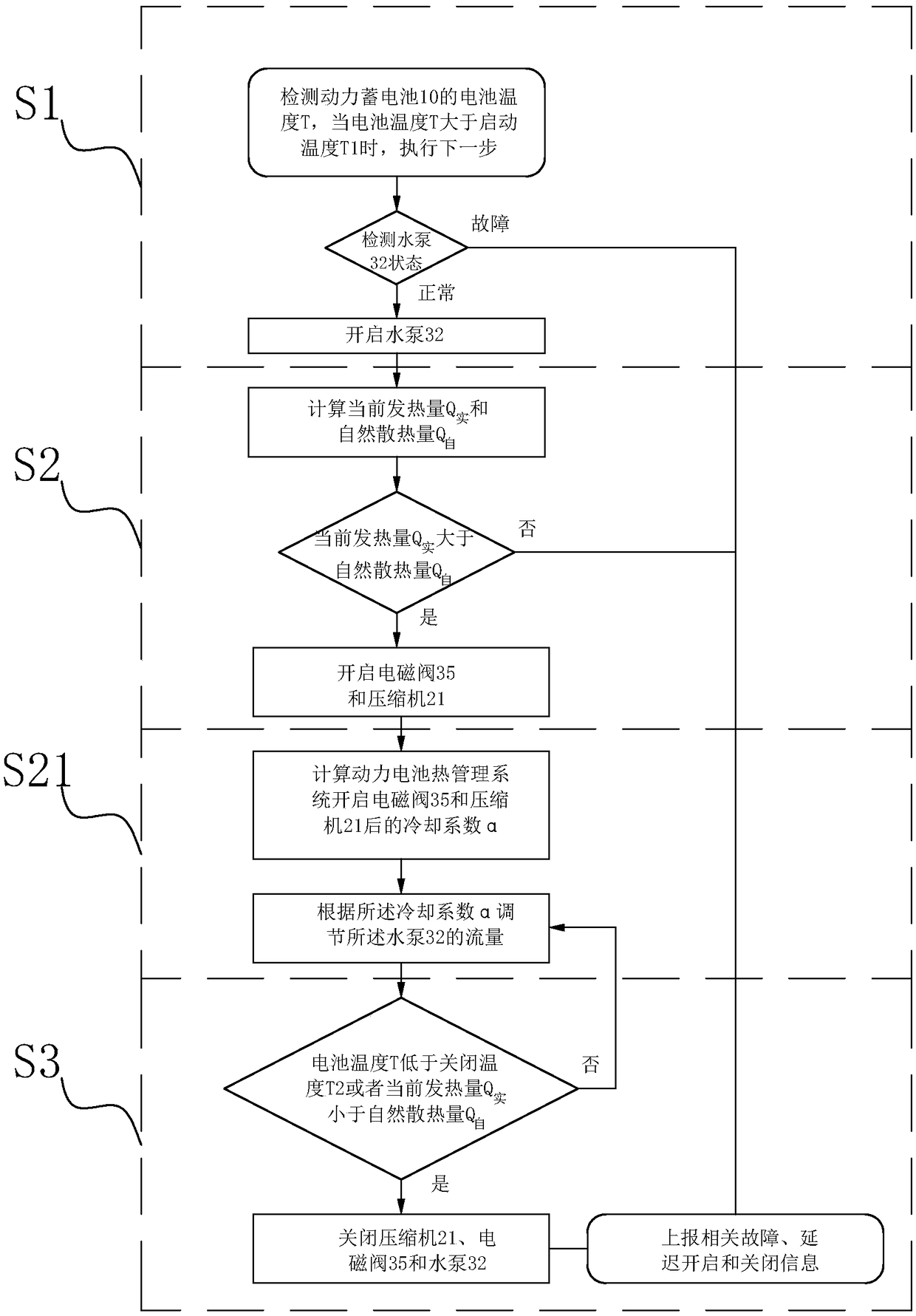

[0040] refer to figure 2 , a control method of a power battery thermal management system of the present invention, comprising the following steps:

[0041] Step S1: Detect the battery temperature T of the power storage battery 10, when the battery temperature T is greater than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com