A high temperature superconducting resistance current limiter, skeleton and superconducting tape winding method

A superconducting tape, high-temperature superconducting technology, applied in the usage of superconducting elements, superconducting magnets/coils, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve the problem of prolonged quench rewarming time , material waste, reduce the electrical insulation of the system, etc., to achieve the effect of reducing the welding process, simplifying the overall structure, and optimizing the bubble retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Further description will be made below in conjunction with the accompanying drawings.

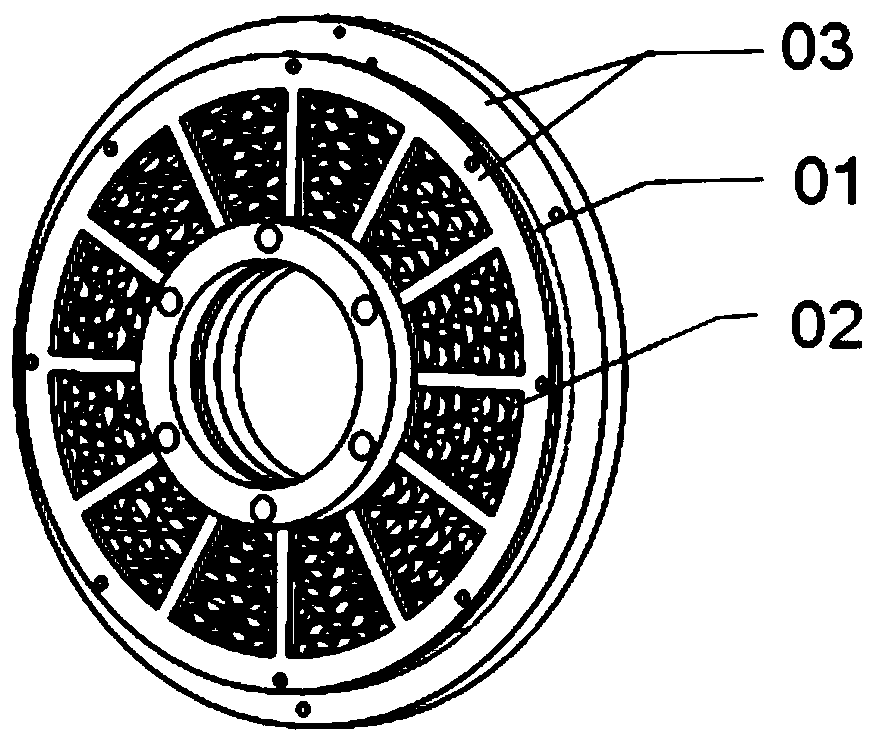

[0053] Such as Figure 5-12 As shown, the model of the high temperature superconducting tape in this embodiment is double-sided encapsulated YBCO superconducting tape, the width of the tape is 12 mm, and the thickness of the tape is 0.35 mm.

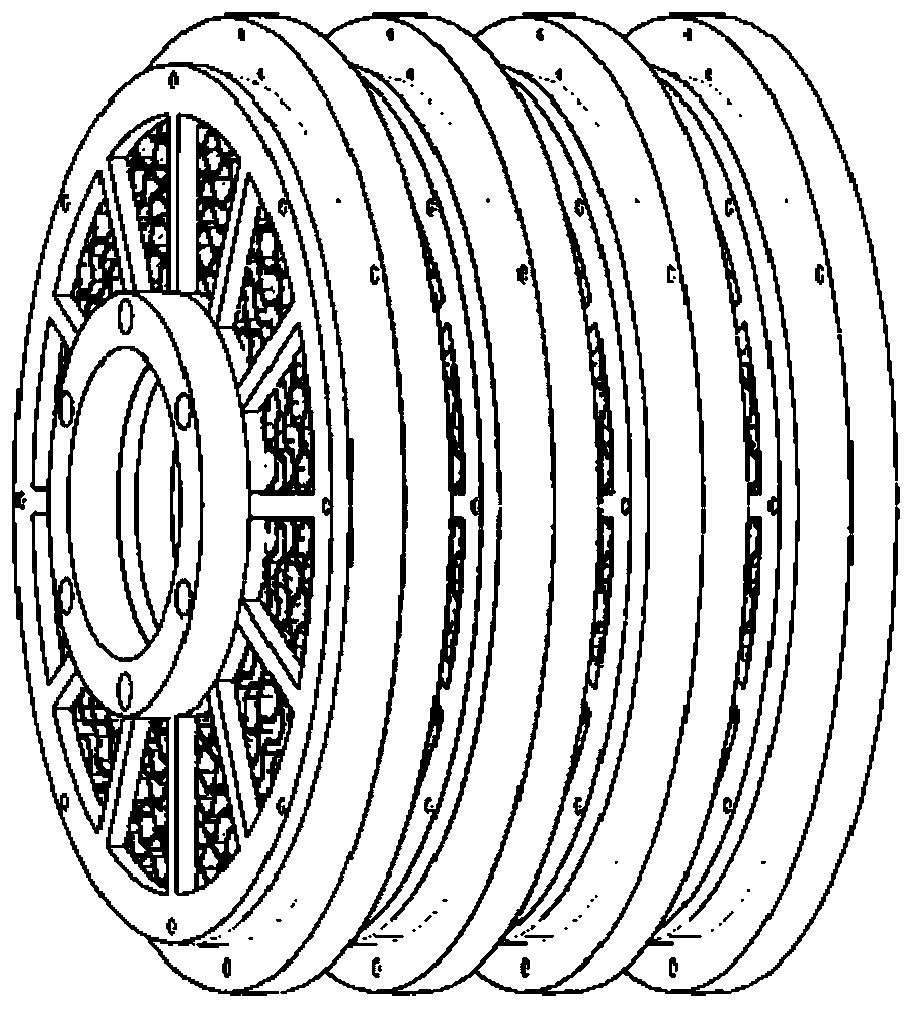

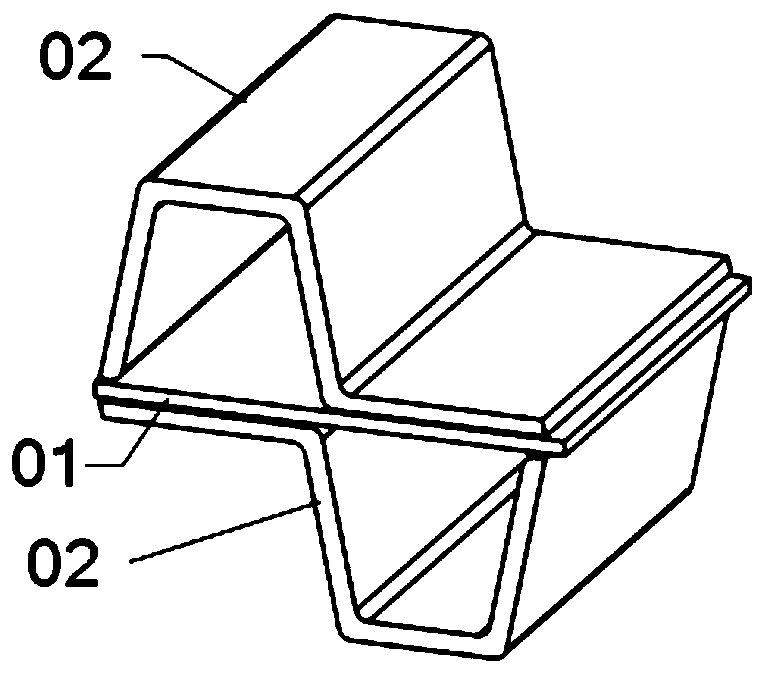

[0054] This embodiment includes a plurality of supporting insulating columns 1 and lead insulating columns 1' that can be arranged according to winding requirements. The supporting insulation column body 1 is provided with a partition card slot 2 for fixing the position of the superconducting strip 11, and the lead wire insulation column body 1' is provided with a lead terminal 2' composed of a copper connecting piece 5 and multiple sets of bolts 6; for Connect and fix the left chassis 8 and the right chassis 7 of multiple insulating columns; the slot structure 10 and the slot structure 9 in the holes of the left chassis 8 and the right chassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com