Large-diameter deep-hole boring device

A large-diameter, deep-hole technology, applied in the field of large-diameter deep-hole boring devices, can solve the problems of processing inner hole volume and visual field limitation, unreasonable processing and maintenance methods, etc., and achieve the effect of flexible action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

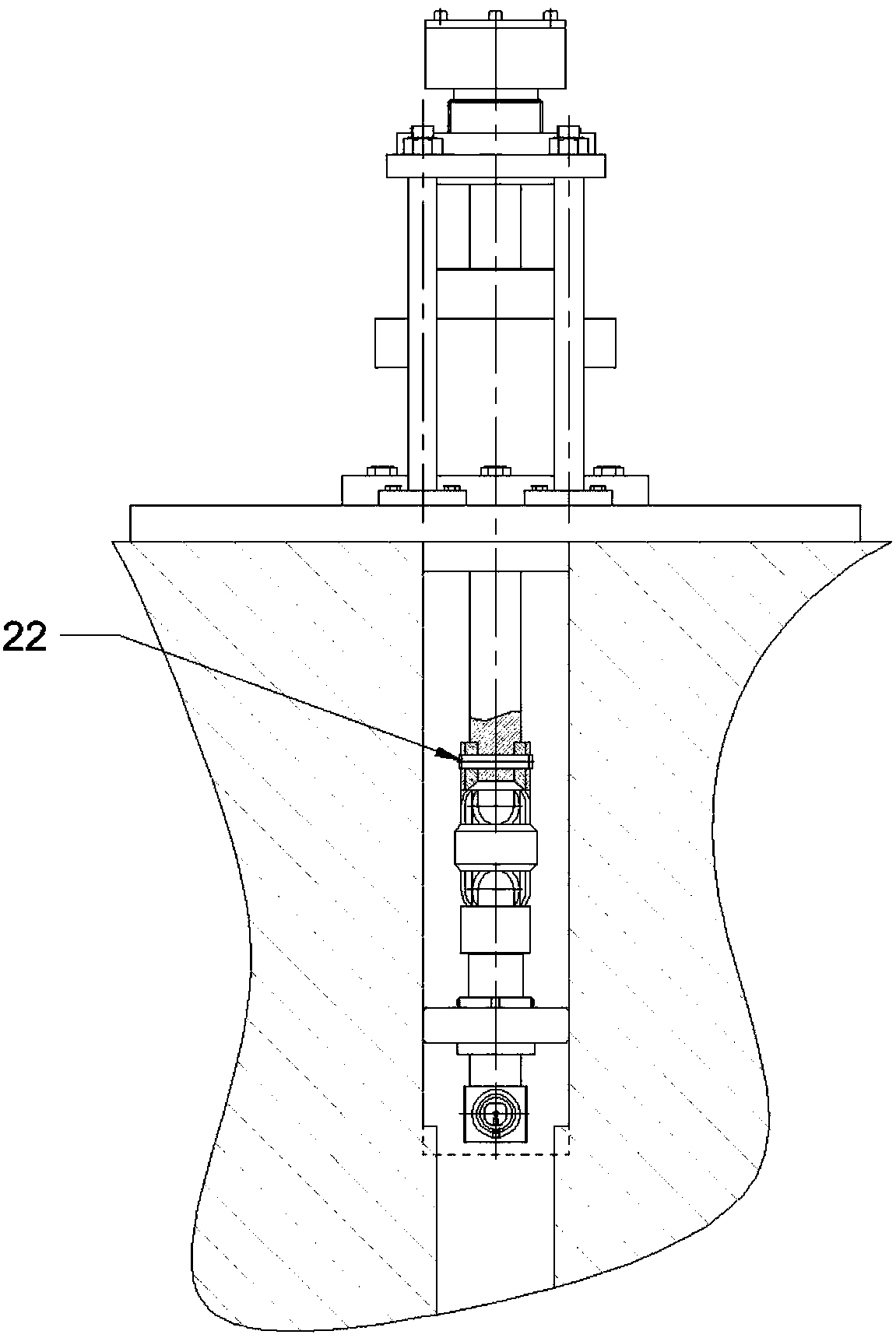

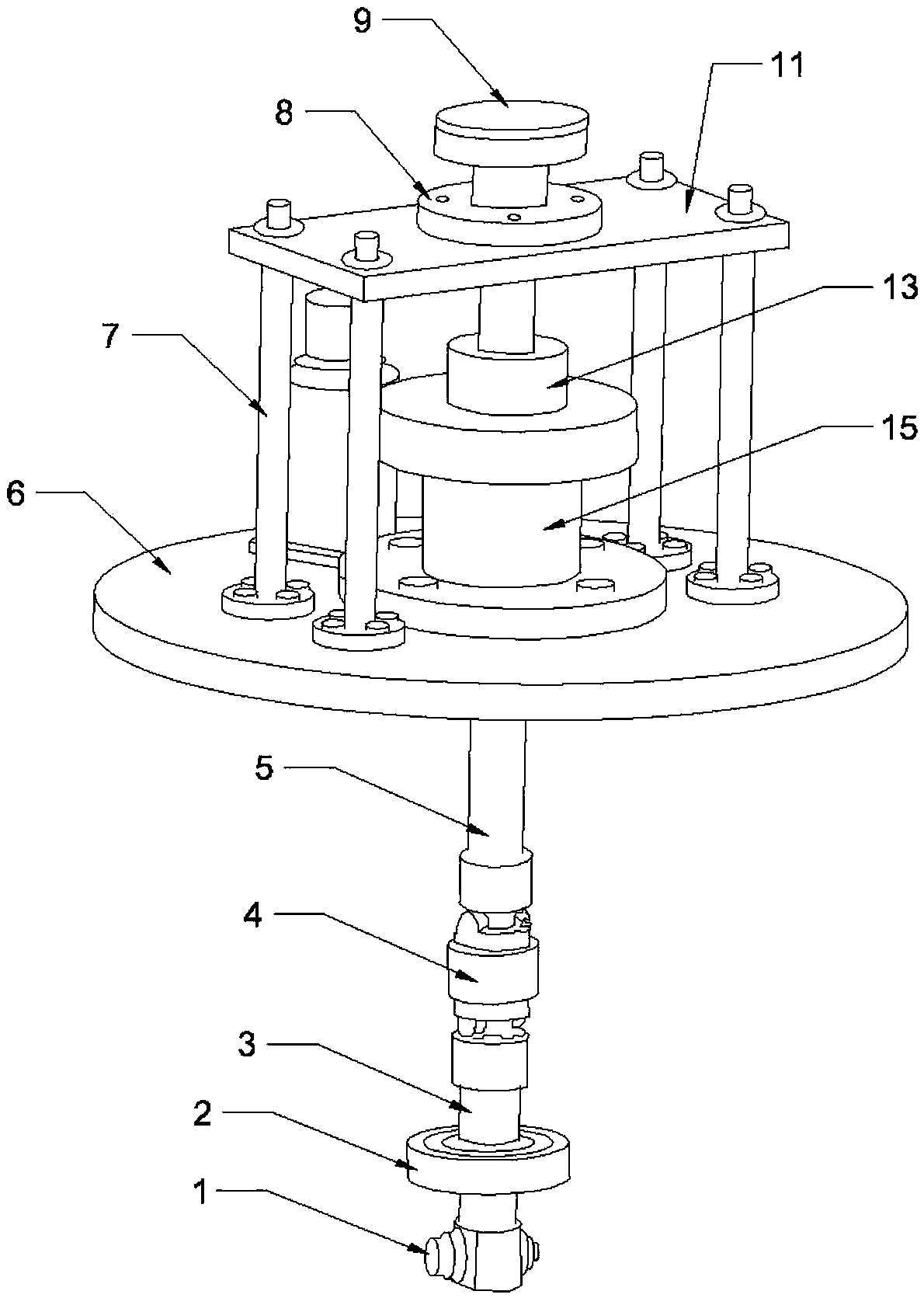

[0032] As shown in the figure, a large-diameter deep hole boring device includes a feed device, a deep groove ball bearing, a short transmission shaft, a ball-twisted universal coupling, a long transmission shaft, a base plate, a support rod, Depth feed nut, long shaft nut, thrust ball bearing, frame plate, flat key, belt wheel sleeve, deep groove ball bearing, belt wheel frame; the base plate is a plate-shaped disc structure, vertical on the upper end of the base plate There is a support rod, and the upper end of the support rod is provided with a frame plate, and a thrust ball bearing is arranged on the frame plate. There is a ball-twisted universal coupling between the short transmission shaft and a tool holder structure at the lower end of the short transmission shaft. The feeding device includes a knife sleeve, a tool holder sleeve, a tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com