An anti-seismic installation method for roof prefabricated parts

An installation method and technology for prefabricated parts, which are applied in earthquake protection, building components, and building materials processing, etc., can solve problems such as failure to meet the requirements of earthquake prevention, waste of resources from construction waste, and complicated processes, and achieve high construction efficiency and guarantee. Good installation and anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

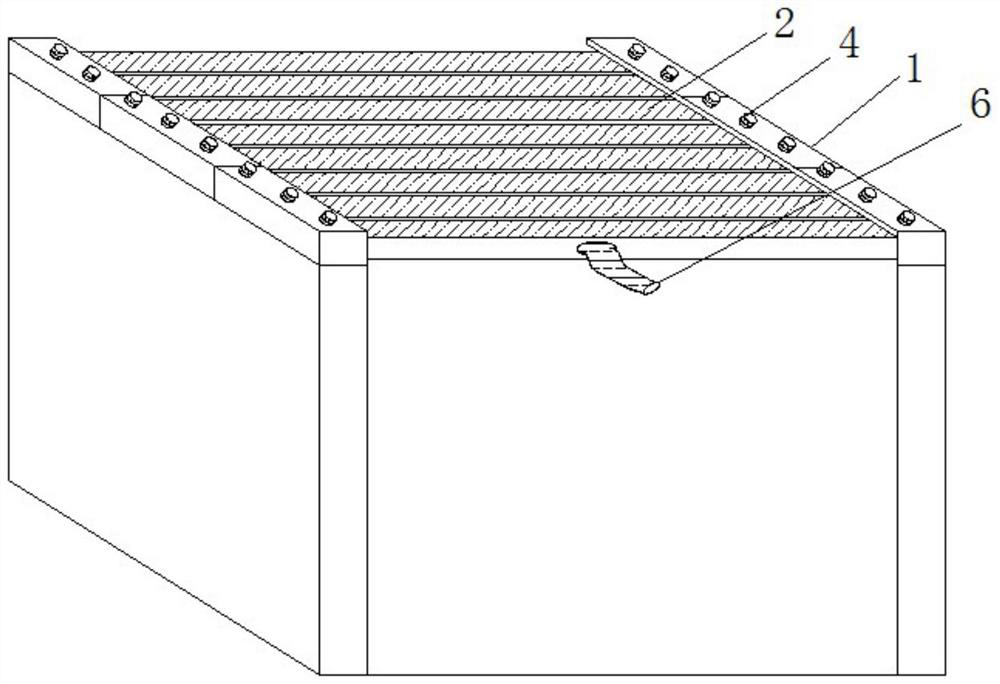

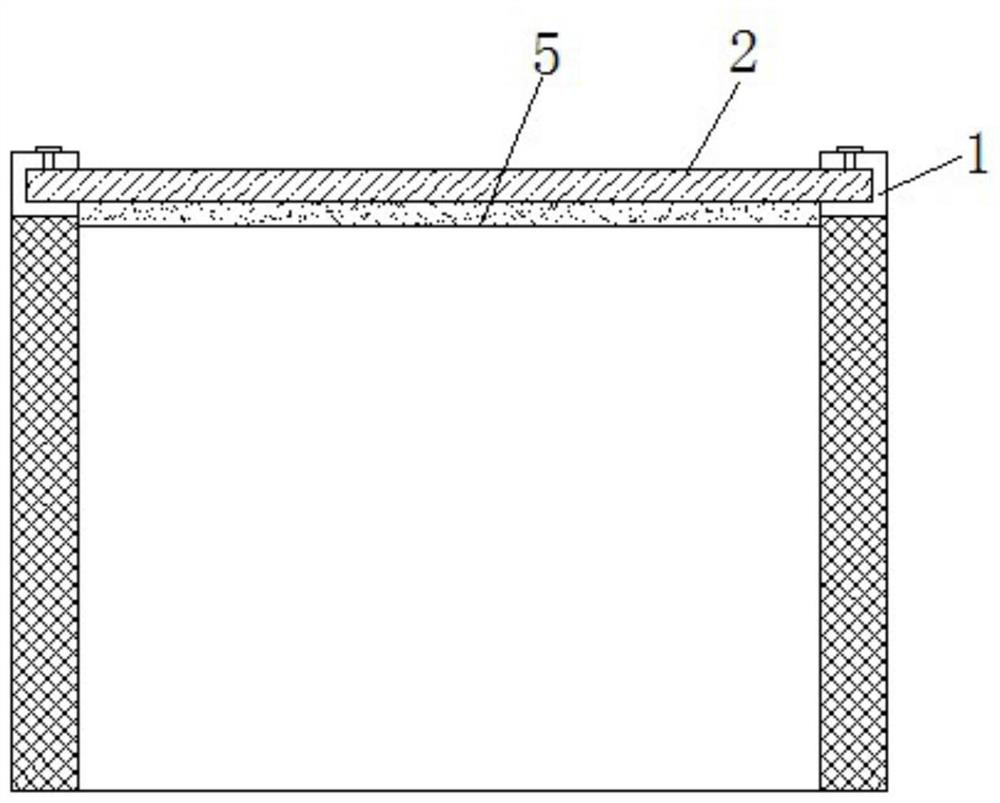

[0035] An anti-seismic installation method for roof prefabricated parts

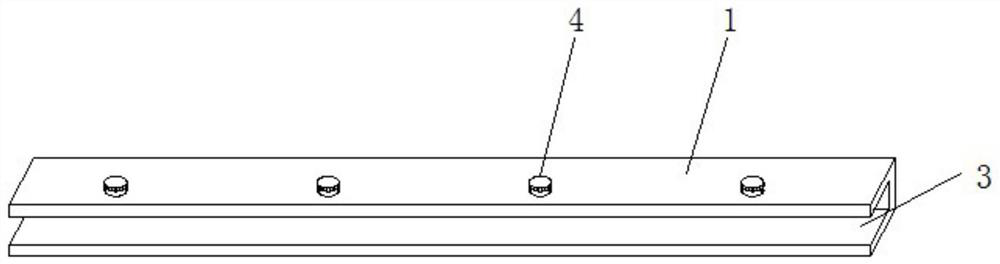

[0036] Step 1: Fasteners

[0037] The ground is pretreated by one or several methods of leveling the ground, digging pits, pre-embedded connectors, and solidified ground, and is connected by screws, expansion bolts, tenon and tenon joints, angle iron connections, snap connections, and hooks , adhesive connection, cement mortar connection or a combination of several methods to build the wall, and then place multiple sets of fixing parts 1 on the top of the wall;

[0038] Step 2: Roof Panel 2

[0039] First pop up the geometric centerline on the upper chord top surface of the roof truss according to the structural layout diagram, pop up the skylight frame and roof panel 2 installation alignment from the mid-span to both ends, then pop up the installation centerline at the end, and pop up the supports on both sides of the upper and lower chords The installation position line of the connector, and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com