A Recurrent Neural Network (RNN)-Based Approach to Predictive Maintenance of Power Production Equipment

A recursive neural network and power production technology, applied in the field of information, to achieve the effect of short time, less labor cost, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

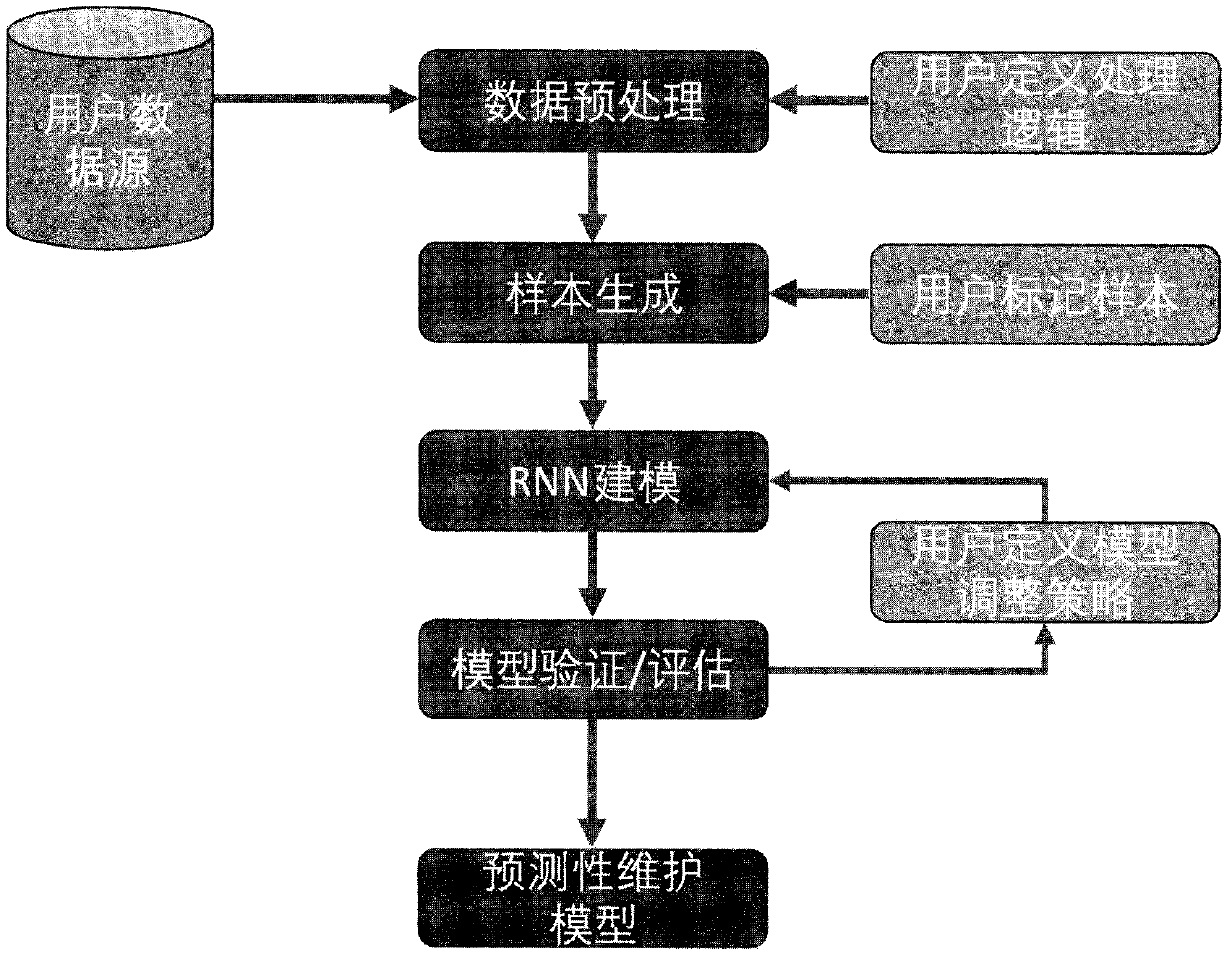

[0043] Such as figure 1 Shown, the present invention is concretely realized as follows:

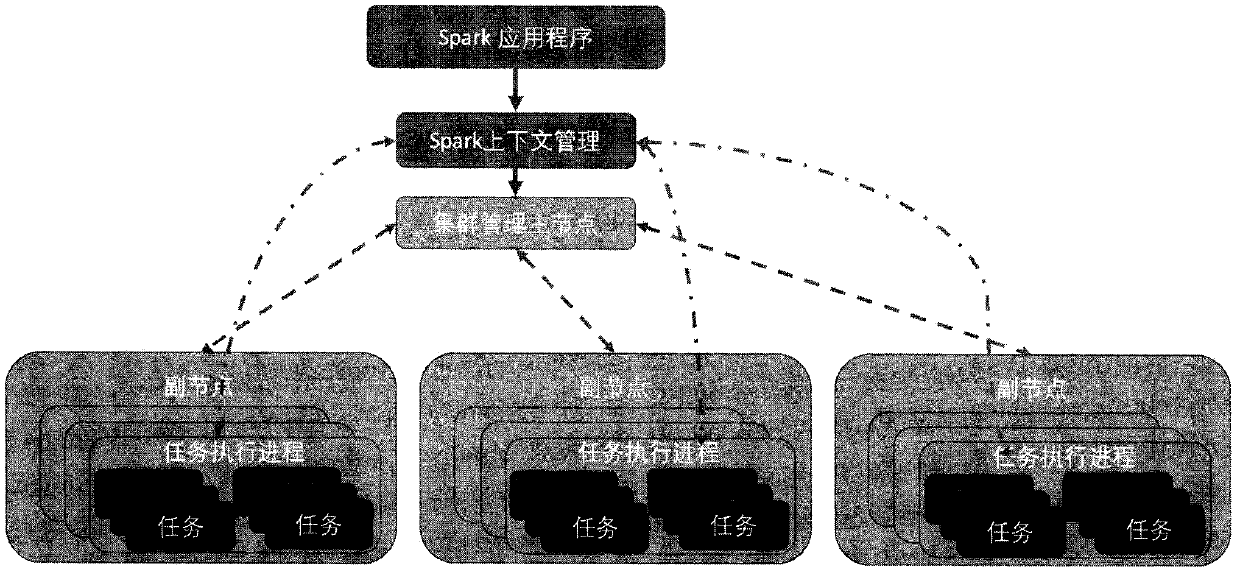

[0044] 1. The whole modeling process of the present invention, including data import, preprocessing, modeling and iterative optimization, is all carried out in the same computing framework, i.e. Apache Spark (see figure 2 ). Spark provides a distributed parallel computing engine. The user application defines the data structure and processing process to be processed by extending the Spark RDD. Spark can transparently convert the user-defined process into a parallel task, and the data can be distributed accordingly. Use parallel tasks to process on different computing nodes;

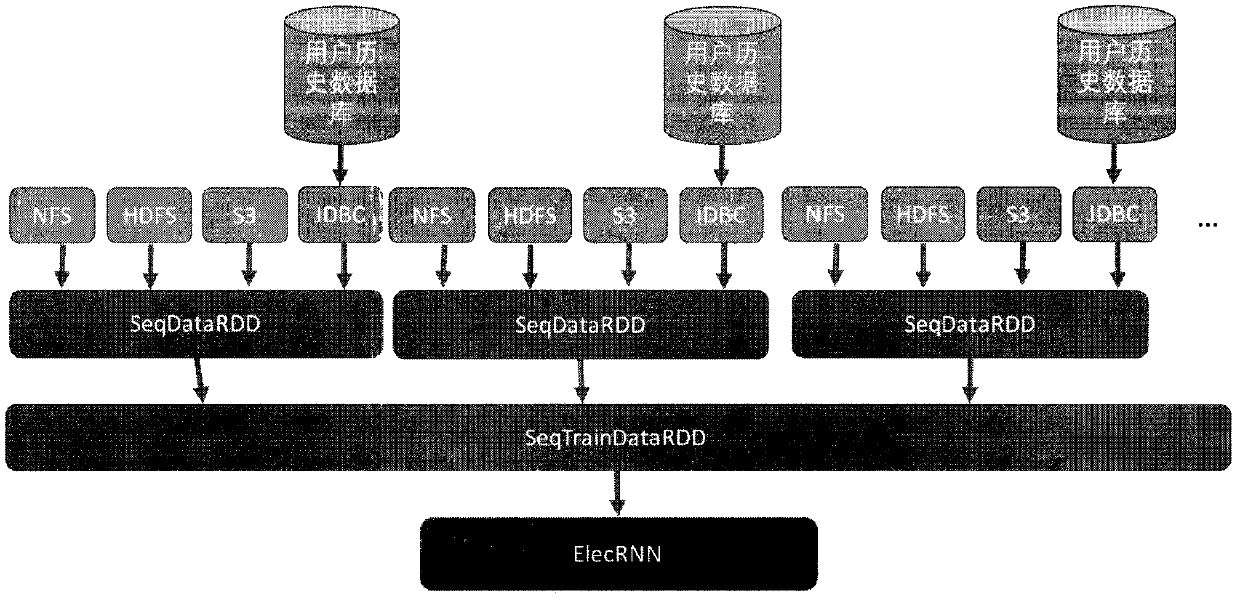

[0045] 2. Import the monitoring historical data of each device in the power production environment through the user data source, select the records of the past 2 years, and generate a serialized data sample set at an interval of 1 hour. The 2-year data samples of a single sensor are 24X 365X 2 = 17520. For possib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com