Novel whipping device

A new type of mixing cup technology, which is applied in home appliances, applications, kitchen utensils, etc., can solve the problems of inability to stir, complicated structure of the whipping device, and increased energy consumption of the body, so as to achieve improved whipping effect, delicate food taste, and improved convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

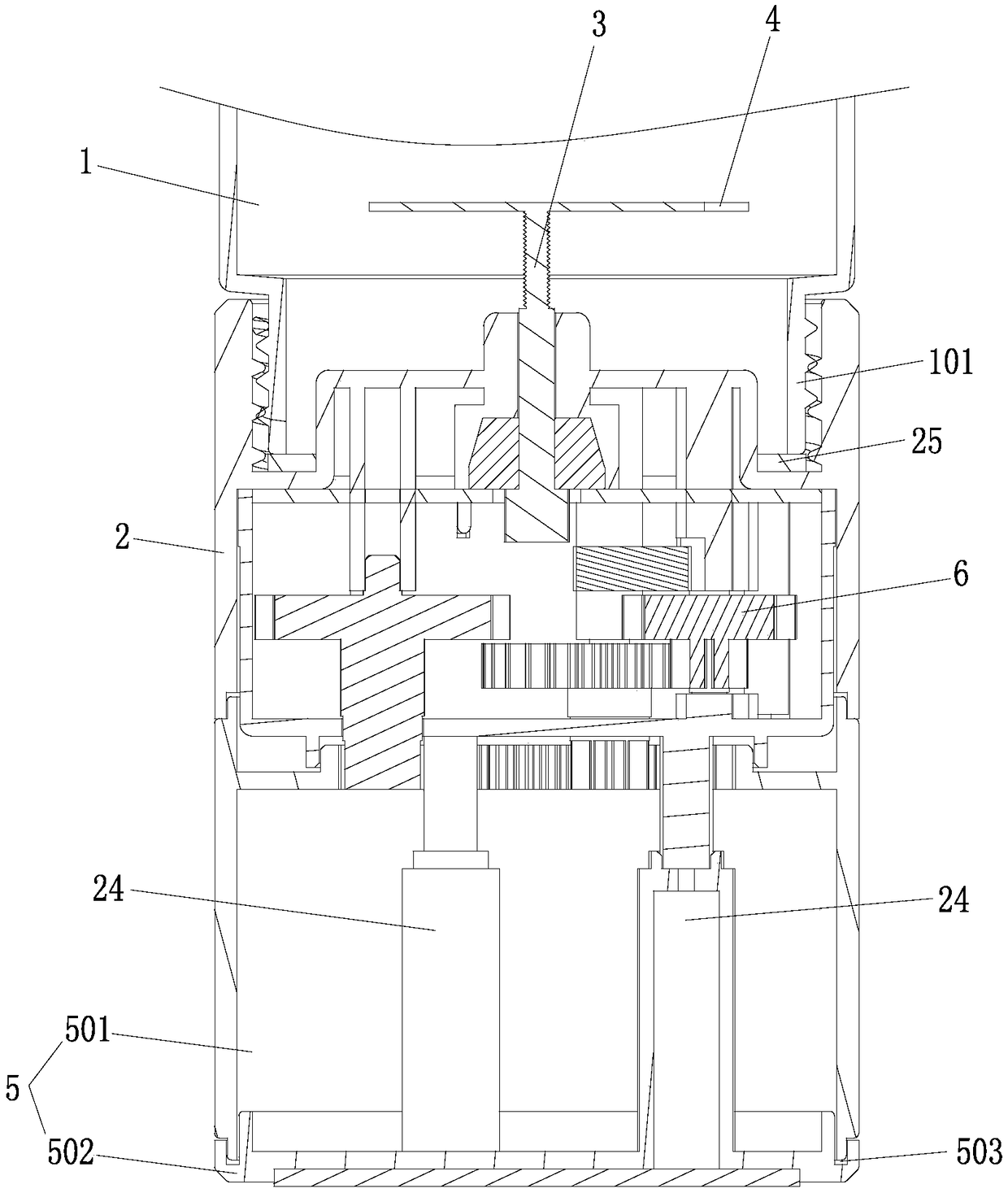

[0024] The first embodiment: as figure 1 As shown, a new type of whipping device includes a stirring cup 1, a knife seat 2 is detachably installed on the mouth 101 of the stirring cup 1, a knife shaft 3 is rotatably connected to the knife seat 2, and a stirring shaft 3 is installed on the knife shaft 3. Knife 4, the handle 5 is rotatably connected to the knife seat 2, and the gear assembly 6 connected with the knife shaft 3 is installed in the knife seat 2, and the gear assembly 6 drives the knife shaft 3 by turning the handle 5 clockwise or counterclockwise to realize one-way Rotate, the whipping device of this structure can enable the user to rotate the handle 5 repeatedly in the clockwise or counterclockwise direction, so that the mixing knife 4 can be quickly rotated in the direction of the blade for whipping, which can improve the convenience of whipping. The user only needs to use the forearm The central axis drives the hand holding the handle 5 to twist repeatedly at hi...

no. 2 approach

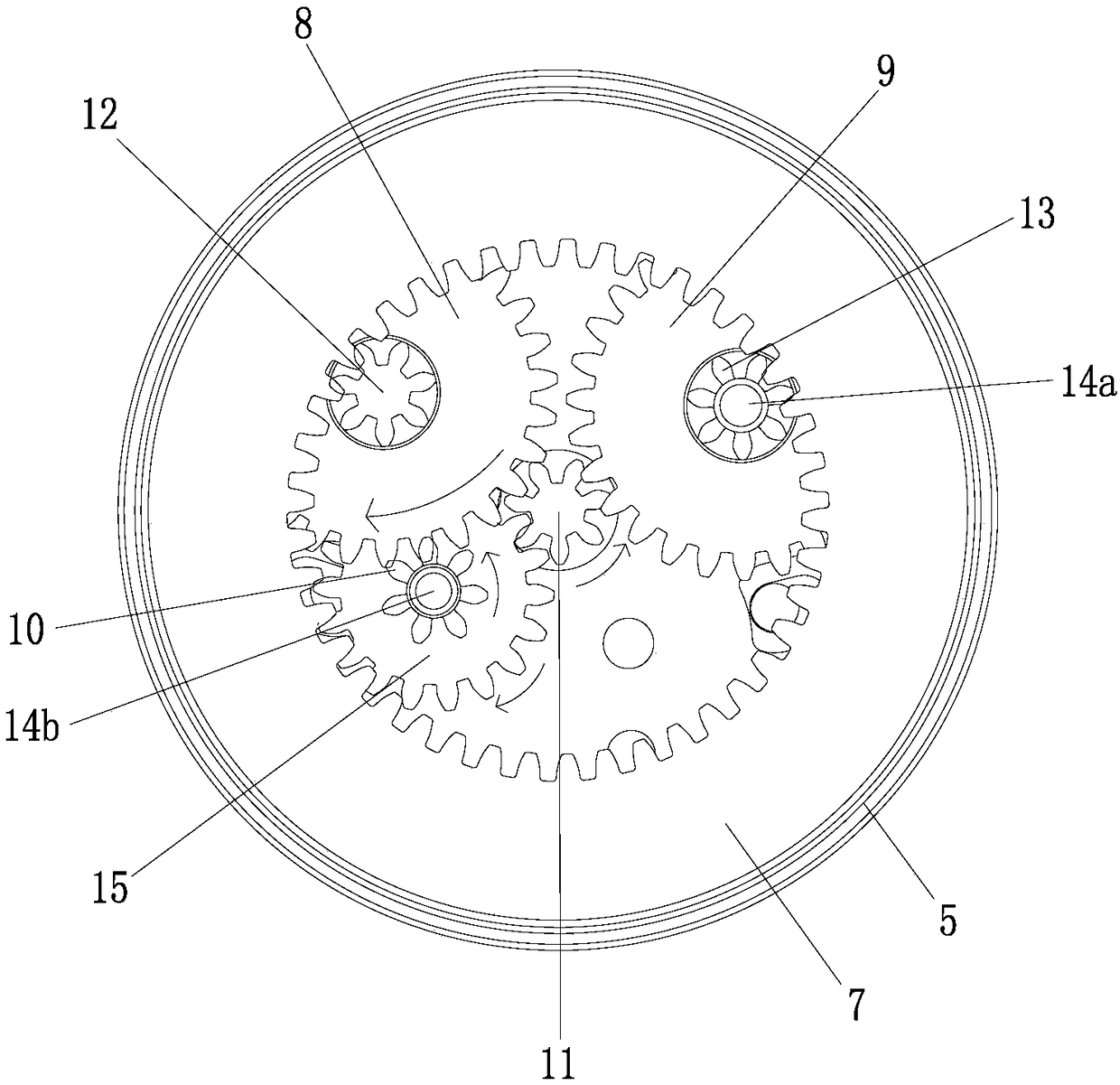

[0025] The second embodiment: as figure 2 As shown, the gear assembly 6 includes an annular internal gear 7, a forward gear 8, a reverse gear 9, a steering gear 10, and a sun gear 11. The annular internal gear 7 is fixedly installed in the handle 5, and the central axis of the forward gear 8 Connected with the first driving gear 12, the reverse gear 9 is connected with the second driving gear 13 through the rotation of the first one-way bearing 14a, the first driving gear 12 and the second driving gear 13 mesh with the annular internal gear 7 respectively, forward The gear 8 meshes with the steering gear 10, and the steering gear 10 is rotatably connected with the steering speed-up gear 15 through the second one-way bearing 14b. The steering speed-up gear 15 meshes with the central gear 11, and the central gear 11 is fixedly installed on the cutter shaft 3. The gear 9 meshes with the central gear 11. The gear assembly 6 of this embodiment simplifies the structure of the gear ...

no. 3 approach

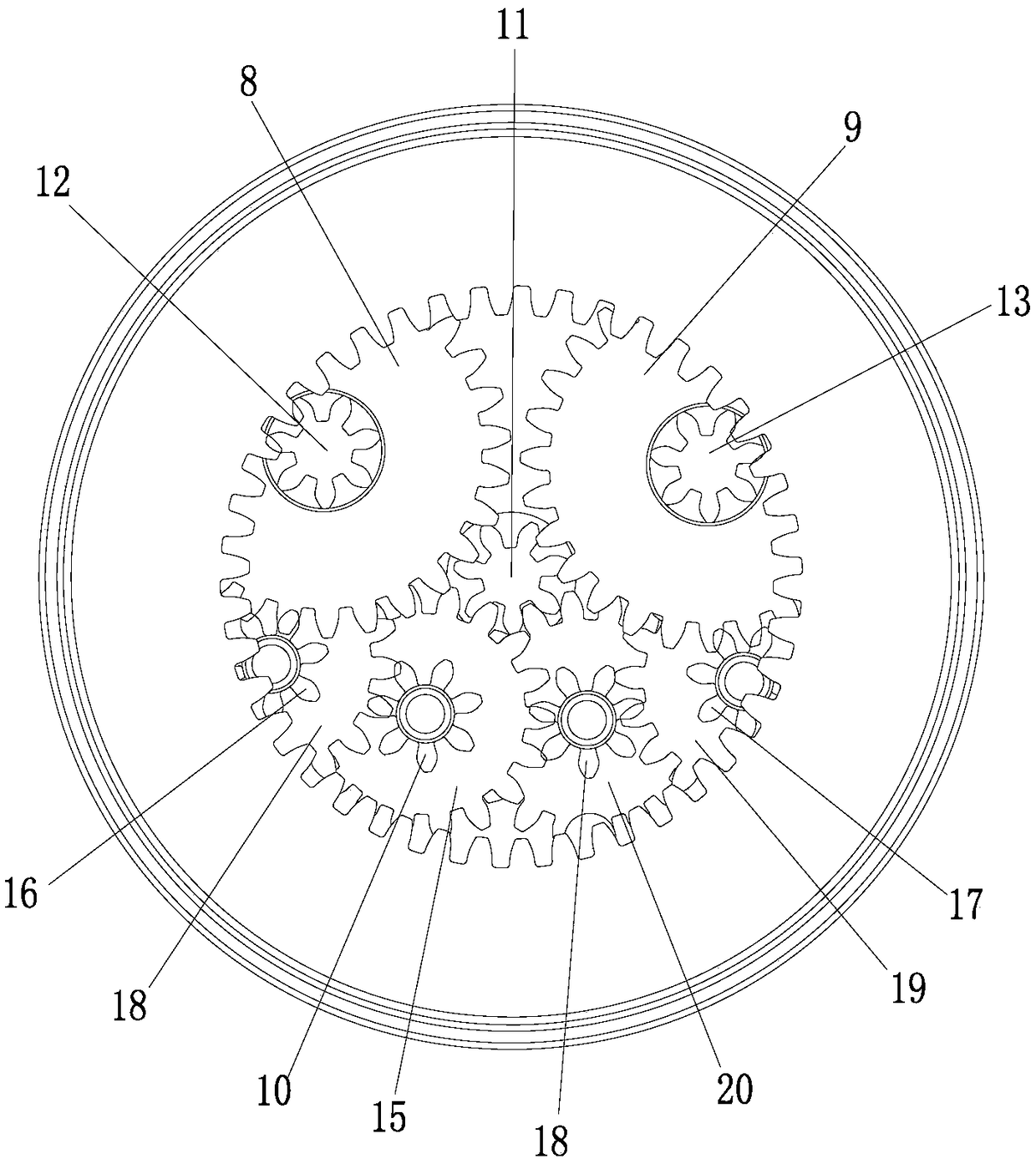

[0028] The third embodiment: as image 3As shown, the gear assembly includes an annular internal gear 7, a forward gear 8, a reverse gear 9, a steering gear 10, a first intermediate gear 16, a second intermediate gear 17, a transmission gear 18 and a sun gear 11, and the annular internal gear 7. It is fixedly installed in the handle 5. On the central axis of the forward gear 8 and the reverse gear 9, the first driving gear 12 and the second driving gear 13 are respectively connected, and the first driving gear 12 and the second driving gear 13 are connected with the annular The internal gear 7 meshes, and the first intermediate gear 16 and the second intermediate gear 17 are swingably installed in the tool holder 2. The first speed-up gear 18 and the second intermediate gear 18 are respectively connected on the central axis of the first intermediate gear 16 and the second intermediate gear 17. The speed-up gear 19, the first intermediate gear 16 and the second intermediate gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com