Efficient energy-saving and environmentally friendly oil dirt cleaning device and process

A high-efficiency, energy-saving, cleaning device technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient operation, large amount of cleaning agent used, and low cleaning efficiency, so as to save cleaning time , save cleaning agent, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

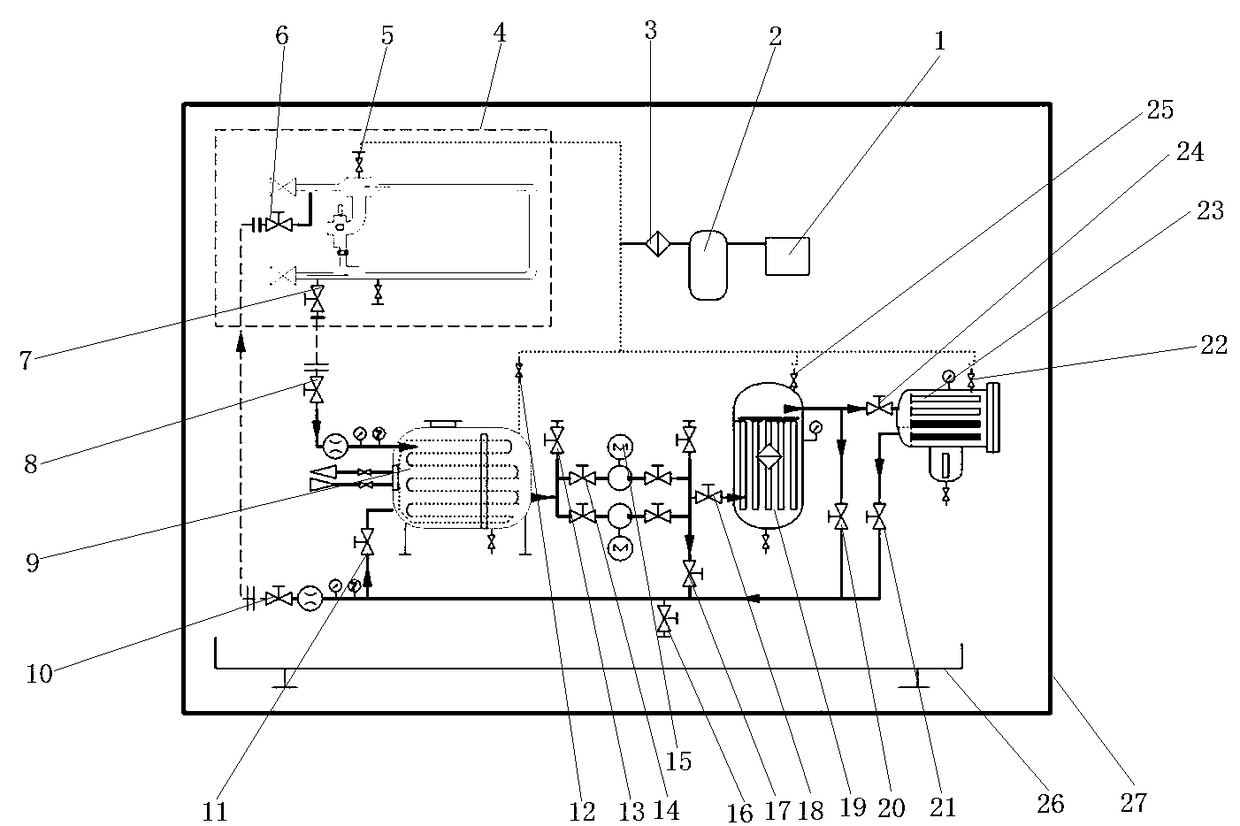

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] A high-efficiency, energy-saving and environment-friendly grease cleaning device, comprising a skid-mounted chassis 26, a frame 27, a compressed air system and a cleaning system, the skid-mounted chassis 26 is welded with a frame 27 on four sides, and four corners of the top of the frame 27 are provided with hoisting holes, The top of the skid-mounted chassis 26 is fixedly installed with a cleaning system and a compressed air system; the compressed air system includes an air compressor 1, an air storage tank 2 and a gas filter 3, and the air compressor 1 is connected to the air compressor through a pipeline. The gas storage tank 2 is connected, and the gas storage tank 2 is connected with a gas filter 3 through a pipeline, and the gas filter 3 is connected to the top of the industrial equipment 4 through a gas pipeline and a valve A5. Valve G12, valve M25 and va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com