Punch and stamping device

A stamping device and punch technology, which is applied in the field of stamping, can solve the problems of products and punches getting hot, unable to guarantee the yield and benefit of output products, and slow speed, etc., to achieve increased stamping speed, simple structure, and reduced defect rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

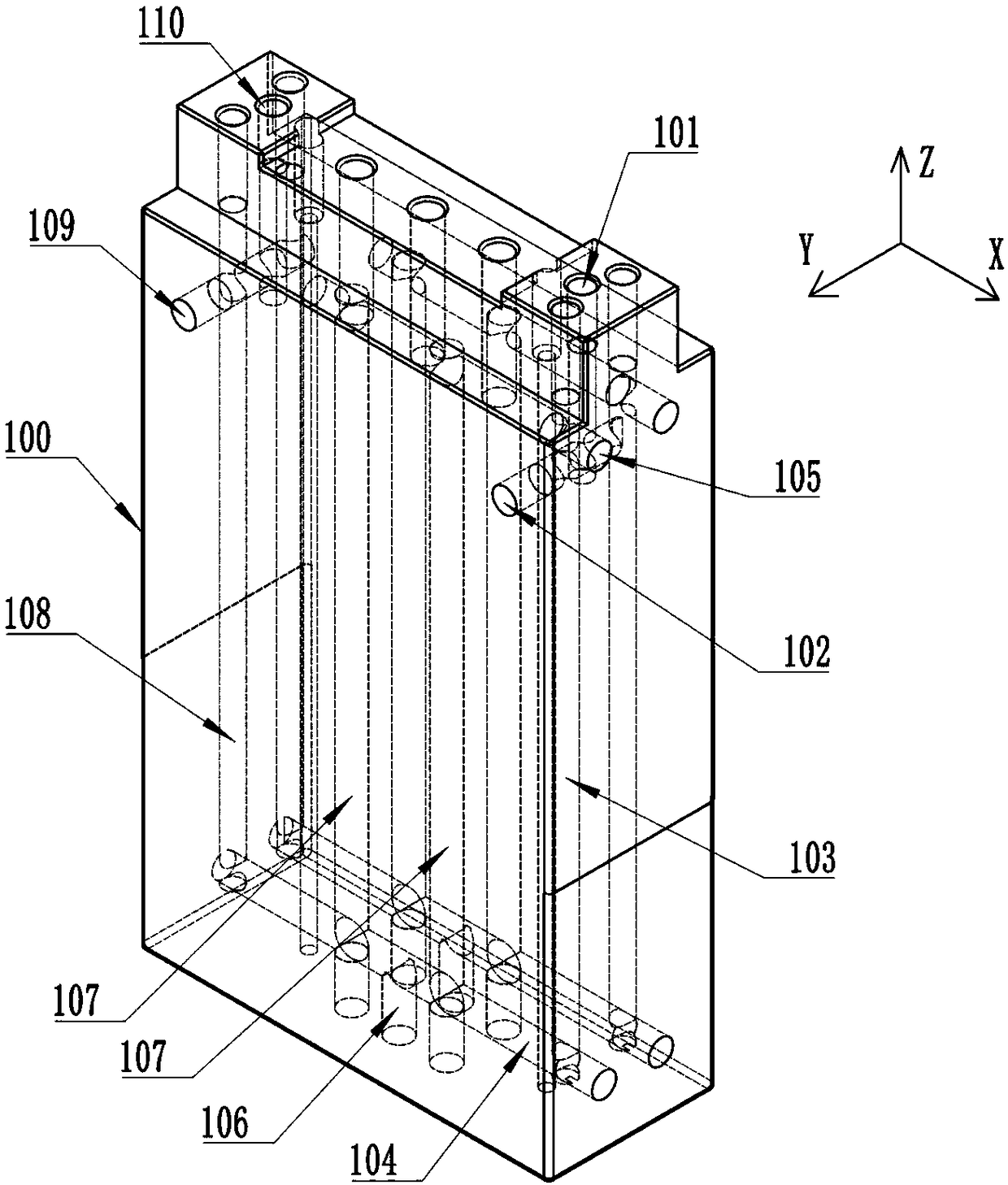

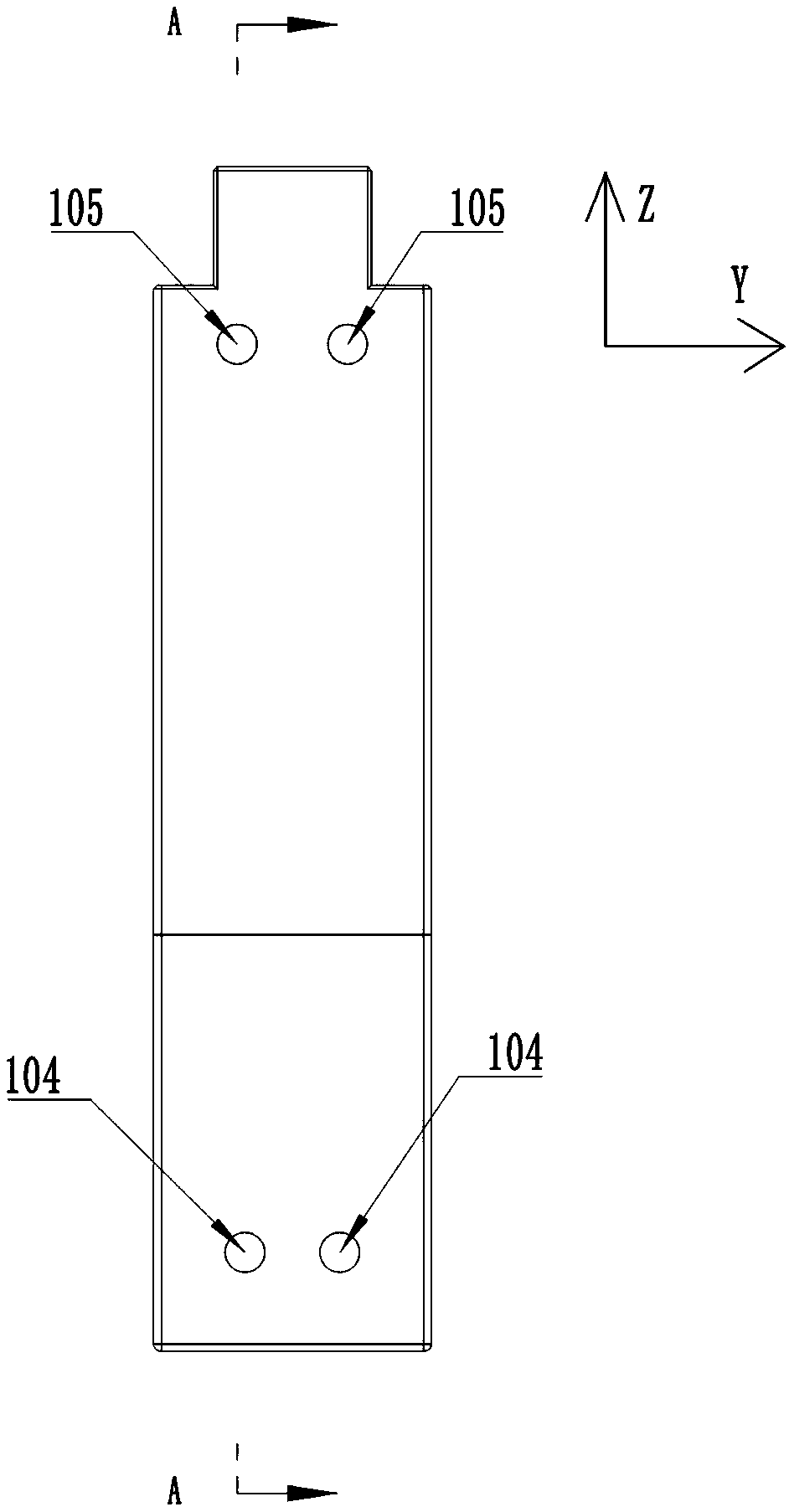

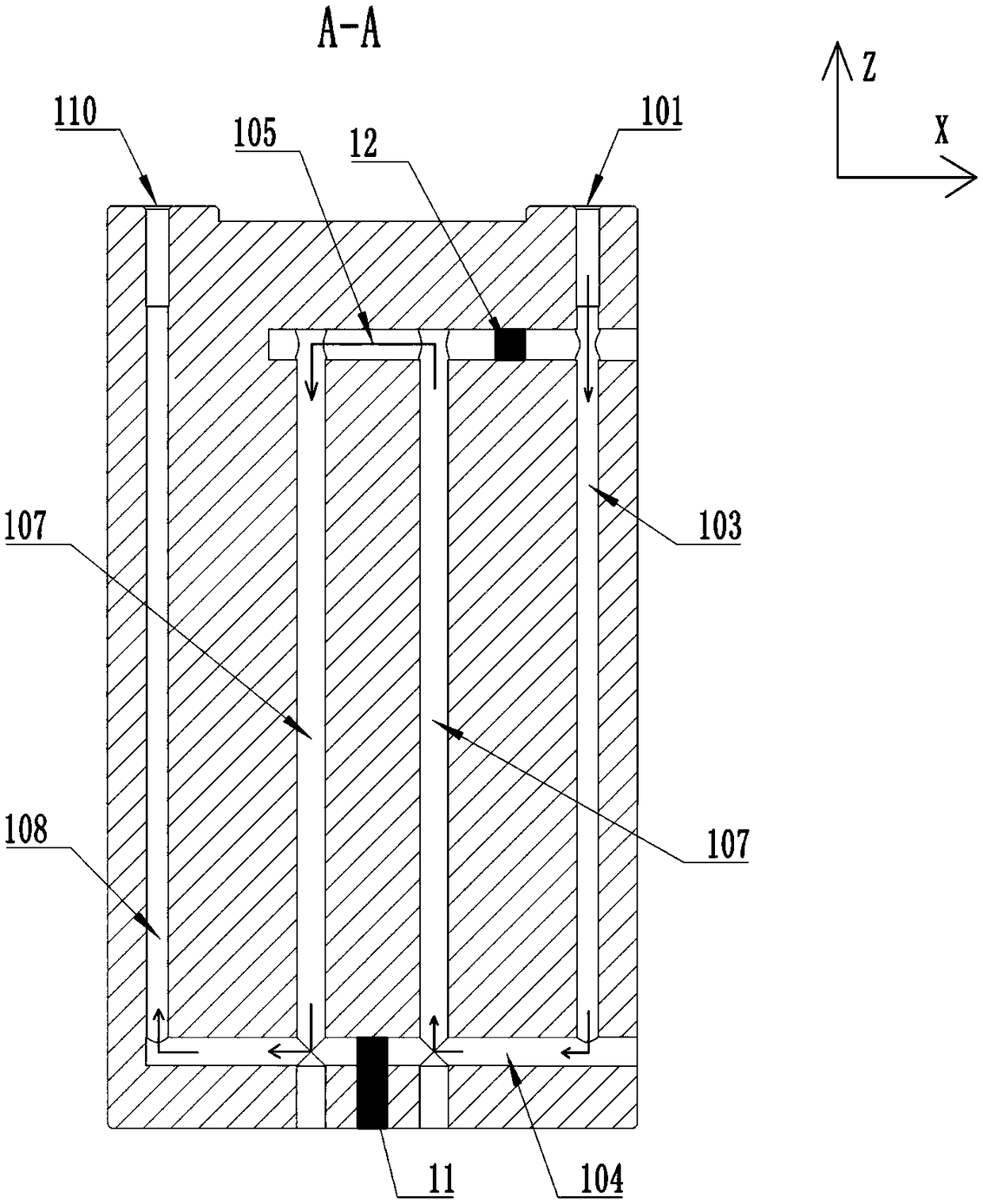

[0035] Please refer to Figure 1 to Figure 3 , a punch 10, including a punch body 100, a water inlet 101 and a water outlet 110 are respectively provided on opposite sides of the top surface of the punch body 100; The hole 102 and the water inlet 101 extend toward the inside of the punch body 100 along the Z-axis and communicate with the water inlet communication hole 102 .

[0036] In the punch body 100, along the water inlet communication hole 102, there are several water inlet holes 103 extending in the Z-axis direction at intervals in the axial direction, and several water inlet holes 103 are connected to the water inlet communication hole 102; each water inlet hole 103 The bottom ends communicate with the first water communication holes 104 extending in the X-axis direction respectively.

[0037] The first water passing hole 104 is distributed with a plurality of water passing holes 107 extending toward the Z-axis direction at intervals along its axial direction; the pun...

Embodiment 2

[0045] Please refer to Figure 5 , a stamping device, including the punch 10 described in the first embodiment above, the top of the punch 10 is fixedly connected with a stamping die handle 20, the stamping die handle 20 drives the punch 10 to move up and down, and the top of the stamping die handle 20 is fixedly connected with a stamping die handle 20. Die handle fixed plate 30.

[0046] A stamping template 50 is arranged directly below the bottom of the punch 10, and the stamping template 50 can drive the punch 10 to descend; Elastic punching rods 60 are provided.

[0047] Specifically, the stamping pin 60 includes an initial state and an elastic state. When the stamping pin 60 is not under pressure, it is the initial state. The top end of the stamping pin 60 is located in the punching groove 51. It becomes an elastic state, and when the pressure leaves, the punching pin 60 resets, and changes from an elastic state to an initial state.

[0048] The bottom end of the stamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com