Tension holding structure of prefabricated track plate prestressed tendon

A technology of prestressed bars and track slabs, applied in the field of rail transit, can solve the problems of prestressed loss of prestressed steel bars, substandard track slabs, affecting track slab performance, etc., and achieves the effect of ensuring qualified tension and overcoming prestress loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

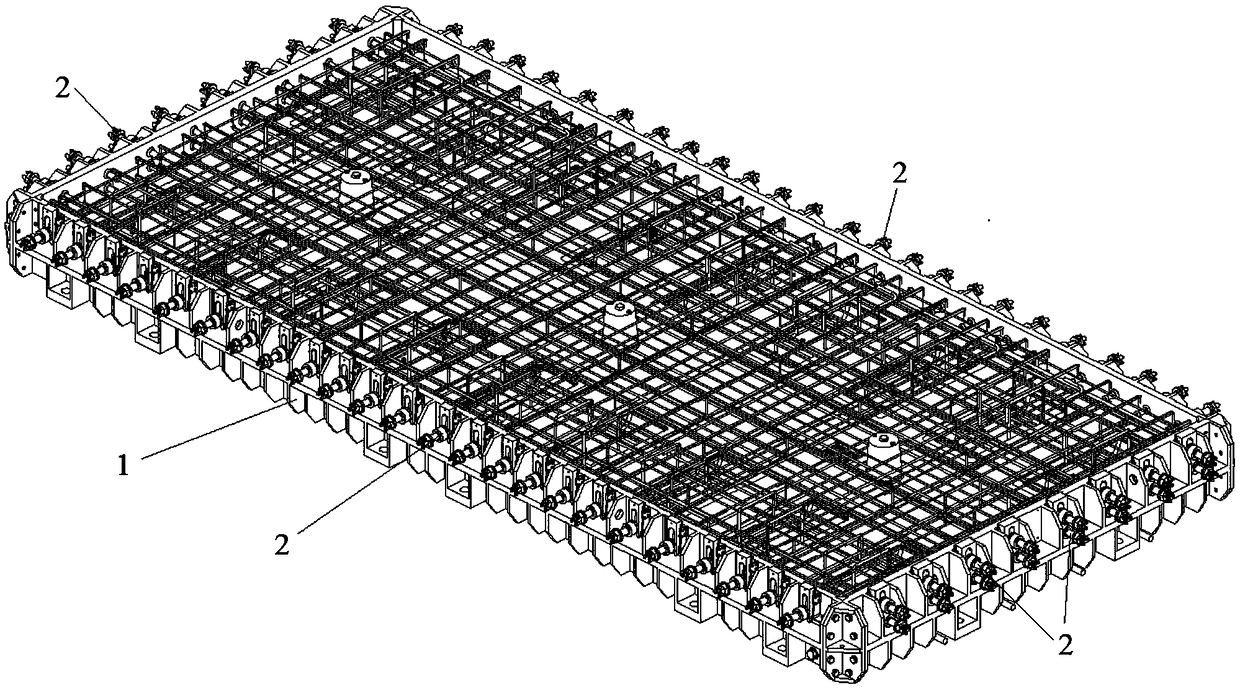

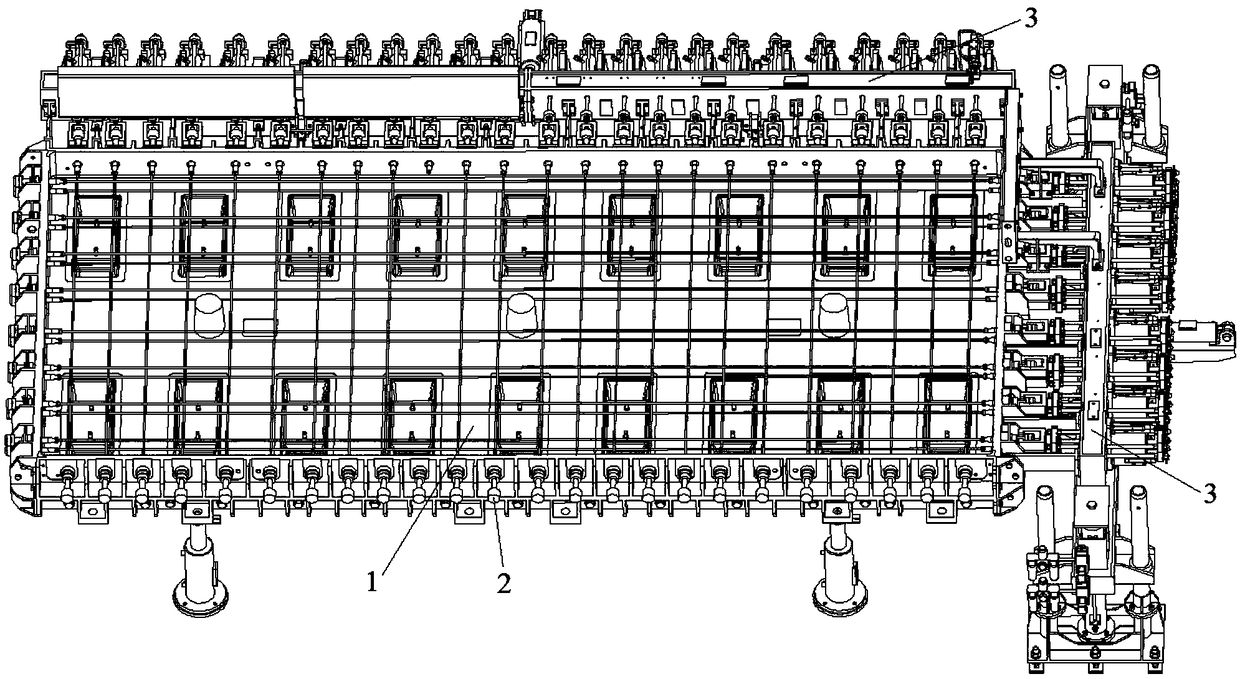

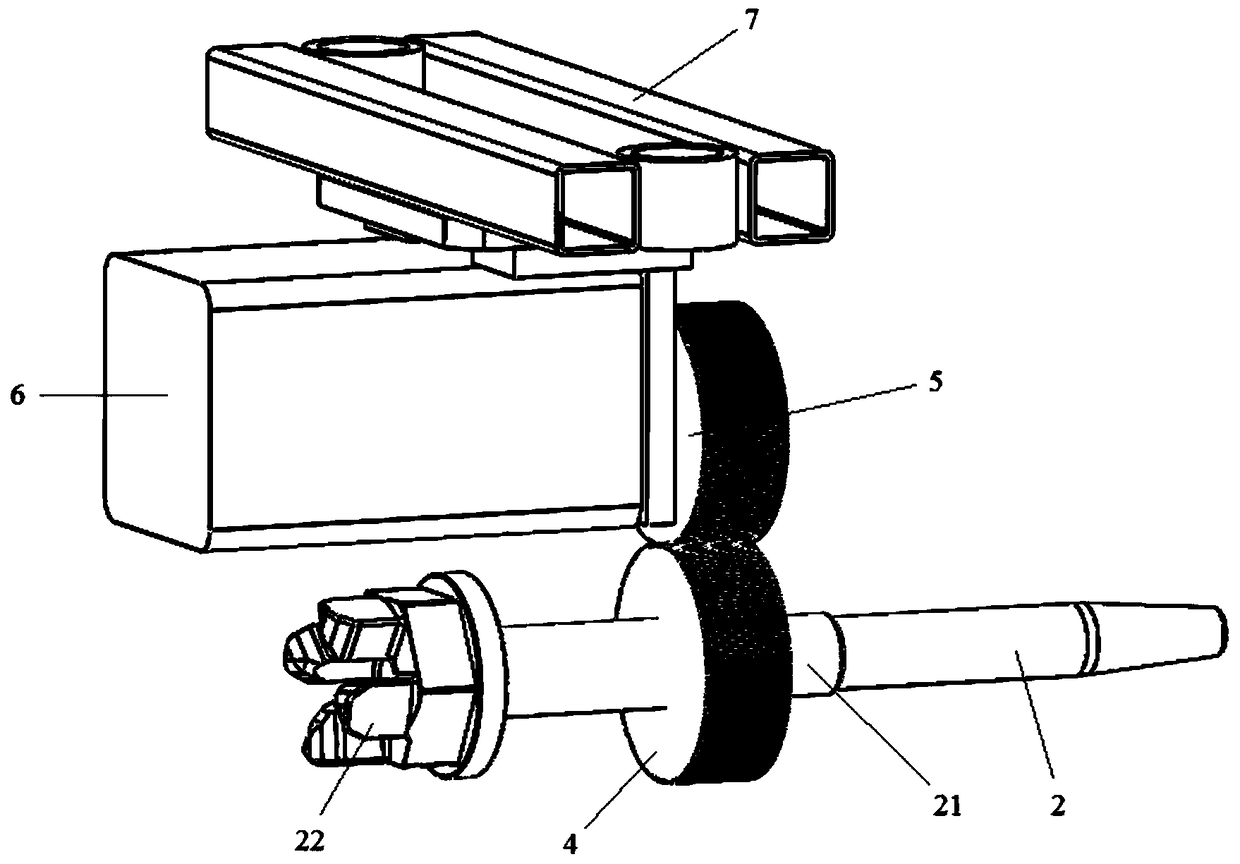

[0052] like Figure 3-6 , 8, a kind of prefabricated track slab prestressed tendon tension holding structure according to the present invention includes the second friction wheel 4, the first friction wheel 5, the first driving part 6, the second driving part, the connecting seat 7. Guide rails 8, bases, elastic components 9, and tension rods 2 connected to both ends of the prestressed reinforcement.

[0053] The tension rod 2 is provided with an externally threaded section 21, and the second friction wheel 4 is provided with an internally threaded hole in the axial center, and the internally threaded hole is adapted to the externally threaded section 21. The first driving part 6 Connect the first friction wheel 5, the connecting seat 7 is slidably connected to the guide rail 8, the connecting seat 7 is connected to the elastic member 9, the elastic member 9 is connected to the base, and the base is connected to The first drive part 6, the elastic force direction provided by ...

Embodiment 2

[0059] like Figure 3-5 , Shown in 7-8, a kind of prefabricated track slab prestressed tendon tension holding structure according to the present invention comprises the second friction wheel 4, the first friction wheel 5, the first driving part 6, the second driving part, The connecting seat 7, the guide rail 8, the base, the elastic member 9, and the tension rod 2 connected to the two ends of the prestressed steel bar are different from Embodiment 1 in that the guide rail 8 is provided with a boss 81, and the connection The seat 7 is located above the boss 81 , the elastic member 9 is sheathed on the guide rail 8 and is located between the connecting seat 7 and the boss 81 , and the elastic member 9 is a spring.

[0060] The diameter of the boss 81 is larger than the outer diameter of the spring, so as to prevent the spring (especially under force) from falling through the boss 81, and the second driving part drives the connecting seat 7 Moving downward along the guide rail ...

Embodiment 3

[0063] The tension and retention structure of prestressed tendons of a prefabricated track slab according to the present invention is different from Embodiment 1 in that the second friction wheel 4 and the first friction wheel 5 in Embodiment 1 are respectively Replaced by the second gear 41 and the first gear 51 .

[0064] The body of the tension rod 2 is provided with an externally threaded section 21, and the second gear 41 is provided with an internally threaded hole in the axial center, the internally threaded hole is adapted to the externally threaded section 21, and the connecting seat 7 is slidably connected to the The guide rail 8, the connecting seat 7 is connected to the elastic member 9, the elastic member 9 is connected to the base, the base is connected to the first driving part 6, and the first driving part 6 is connected to the The first gear 51, the first driving part 6 is used to drive the first gear 51 to rotate, and the second driving part is used to drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com