An anti-slip plate bearing

A plate-type rubber bearing and anti-slip technology, which is applied in bridge parts, bridges, buildings, etc., can solve the problems of low creep, reasonable deformation of beam body over-constraint, high strength, etc., achieve low manufacturing cost and improve anti-skid The effect of moving performance and avoiding the loss of prestress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

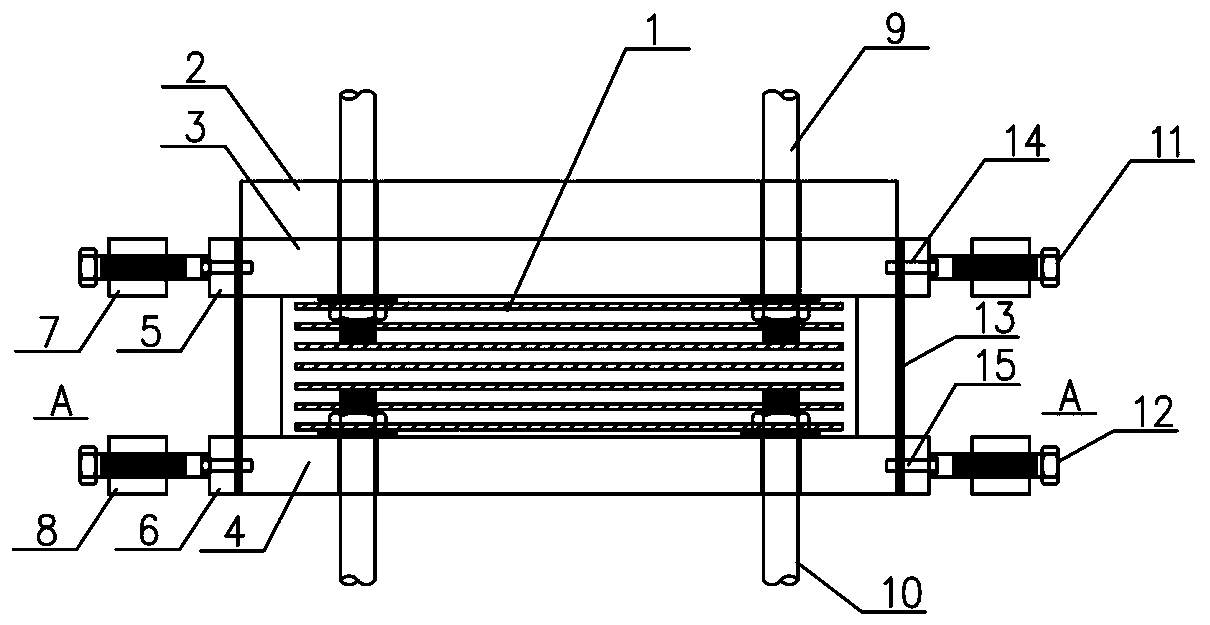

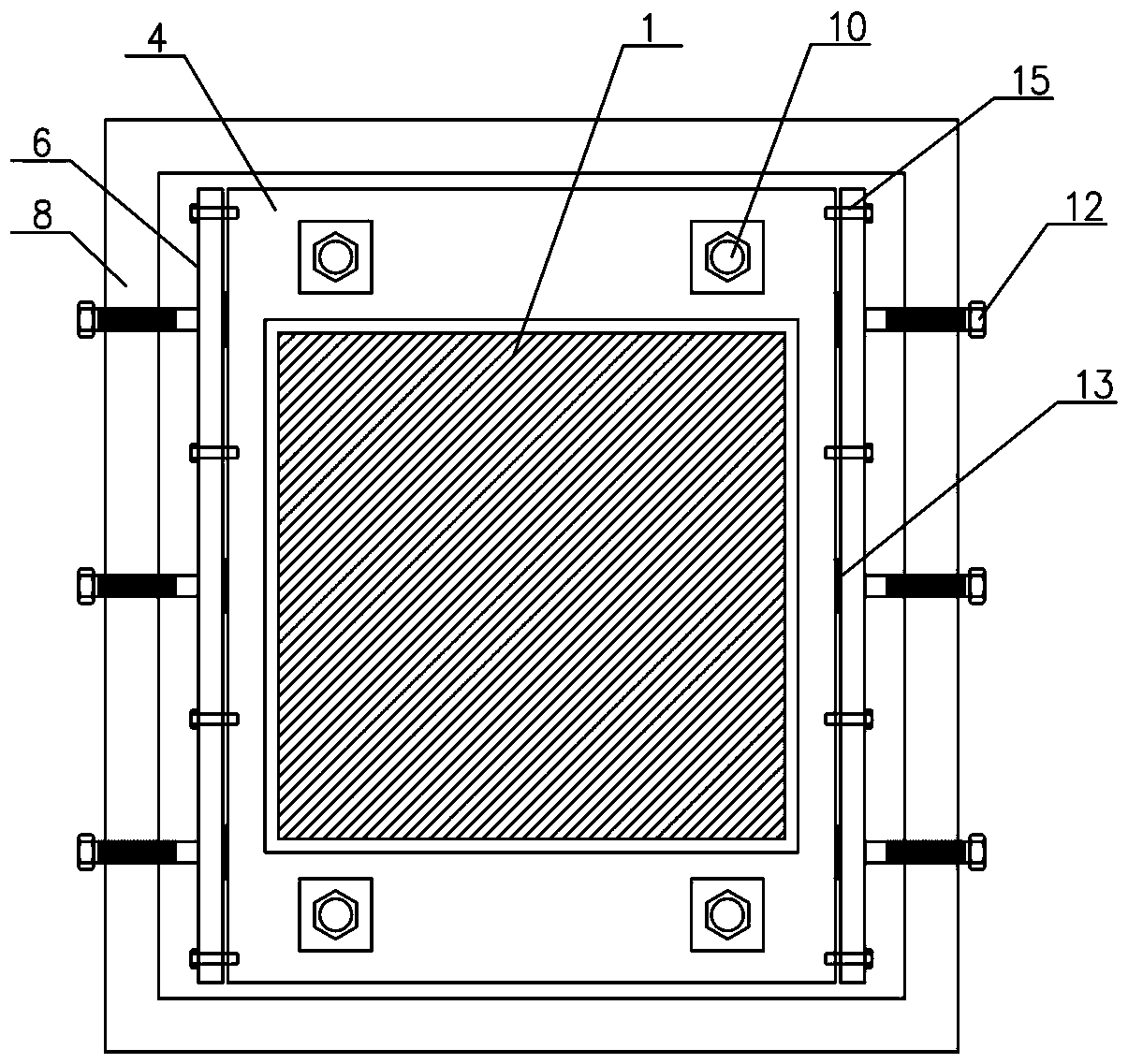

[0016] See attached figure 1 ~ attached figure 2 , the present invention consists of a rectangular plate-type rubber bearing 1, a pre-embedded leveling steel plate 2, an upper support steel plate 3 and a lower support steel plate 4, and the upper support steel plate 3 is provided with a pre-embedded leveling steel plate 2, an upper The top tight plate 5 and the upper ring steel plate 7; the lower support steel plate 4 is provided with the lower top tight plate 6 and the lower ring steel plate 8; the embedded leveling steel plate 2 is set on the upper support steel plate by the upper anchor bar 9 3, the upper anchor bar 9 is an anchor rod with a thread at one end, and is anchored on the upper support steel plate 3 by a nut; On both sides of the upper support steel plate 3; the upper ring steel plate 7 is set outside the upper support steel plate 3 and fixed on the upper clamping plate 5 by the upper clamping bolt 11; the lower clamping plate 6 is a straight strip , and are f...

Embodiment 2

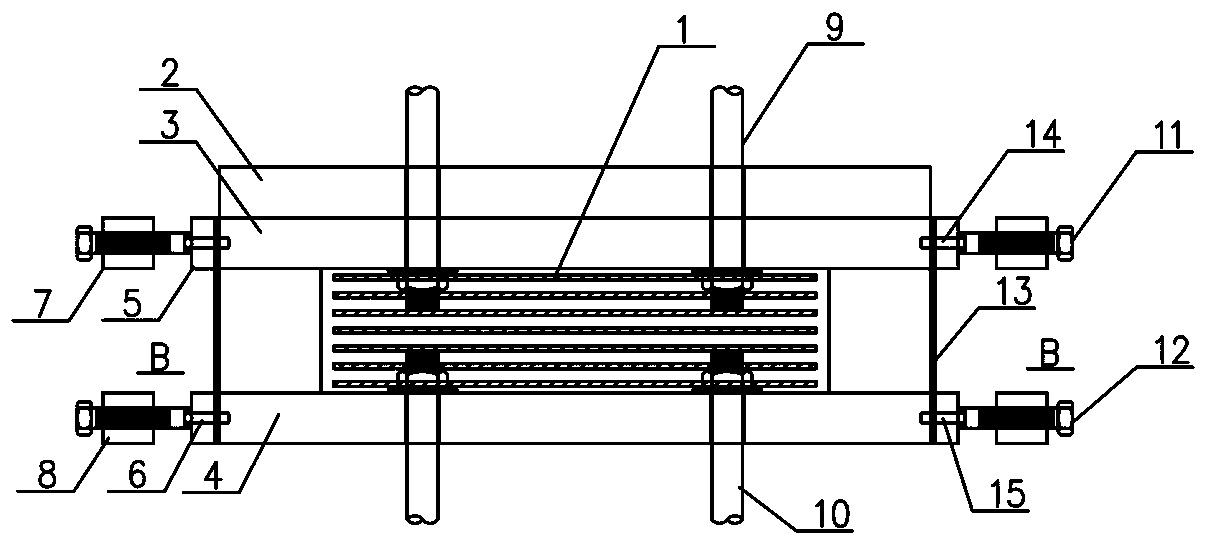

[0019] See attached image 3 ~ attached Figure 4 , The present invention consists of a circular plate rubber bearing 1, a pre-embedded leveling steel plate 2, an upper bearing steel plate 3 and a lower bearing steel plate 4. The upper support steel plate 3 is provided with a pre-embedded leveling steel plate 2, an upper clamping plate 5 and an upper ring steel plate 7; the lower support steel plate 4 is provided with a lower clamping plate 6 and a lower ring steel plate 8; The pre-embedded leveling steel plate 2 is arranged on the upper support steel plate 3 by the upper anchor rib 9, and the upper anchor rib 9 is an anchor rod provided with a thread at one end, and is anchored on the upper support steel plate 3 by a nut; The upper clamping plate 5 is a circular arc plate, and is fixed on both sides of the upper support steel plate 3 by upper bolts 14; the upper ring steel plate 7 is set outside the upper support steel plate 3 and fixed on On the upper clamping plate 5; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com