Virtual reality (VR) mine fully mechanized mining face remote remote tour inspection intervention method

A fully-mechanized mining face and virtual reality technology, which is applied to earthwork drilling, cutting machinery, etc., can solve problems such as poor dust and water vapor effects, affecting execution effects, and poor working face effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

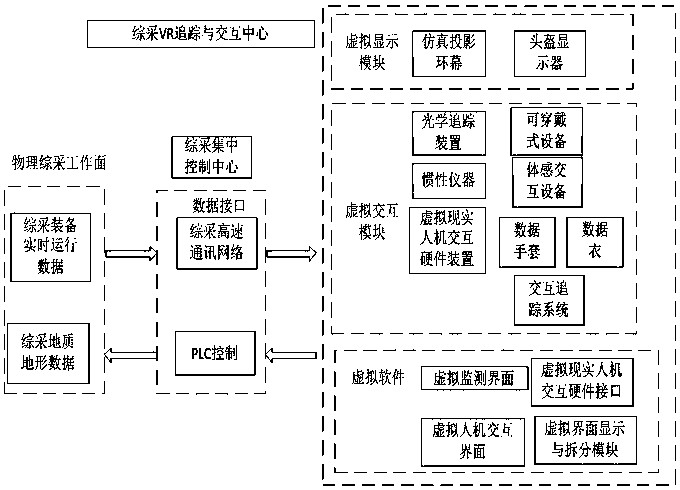

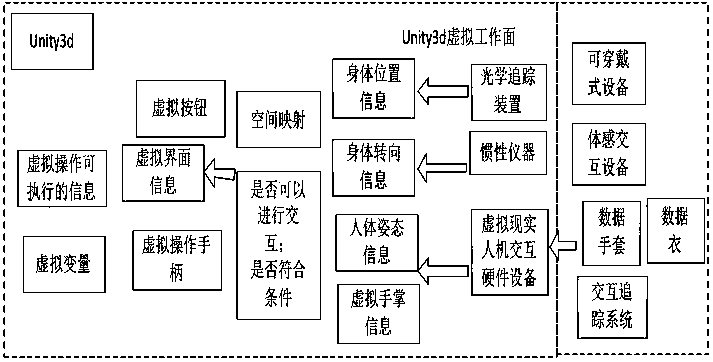

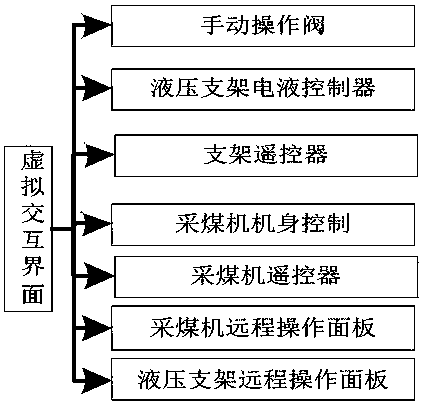

[0037] As shown in the accompanying drawings, the implementation of the above-mentioned remote inspection intervention method of a virtual reality mine fully mechanized mining face provided by the present invention is mainly to solve the problem of manual remote intervention and inspection of the fully mechanized mining face under the coal mine, and to truly turn the miners Liberate from the production site, and put it in the scene of operating equipment in the fully mechanized mining face in a very vivid way, and then monitor the equipment, find problems, and use virtual reality for remote manual intervention and remote control at places far away from the production site. Inspection, to realize the remote inspection intervention of the fully mechanized mining face of the virtual mine that is not in the real world and reproduces its real func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com