Slapper detonator ignition special transfer wire and injection molding method of lead plate thereof

A technology of shock detonators and transfer wires, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve the problems of untrue test data, low hardness of the lead plate, unsuccessful ignition, etc., and achieve accurate and reliable test data and pressure resistance performance. The effect of excellent, excellent ignition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

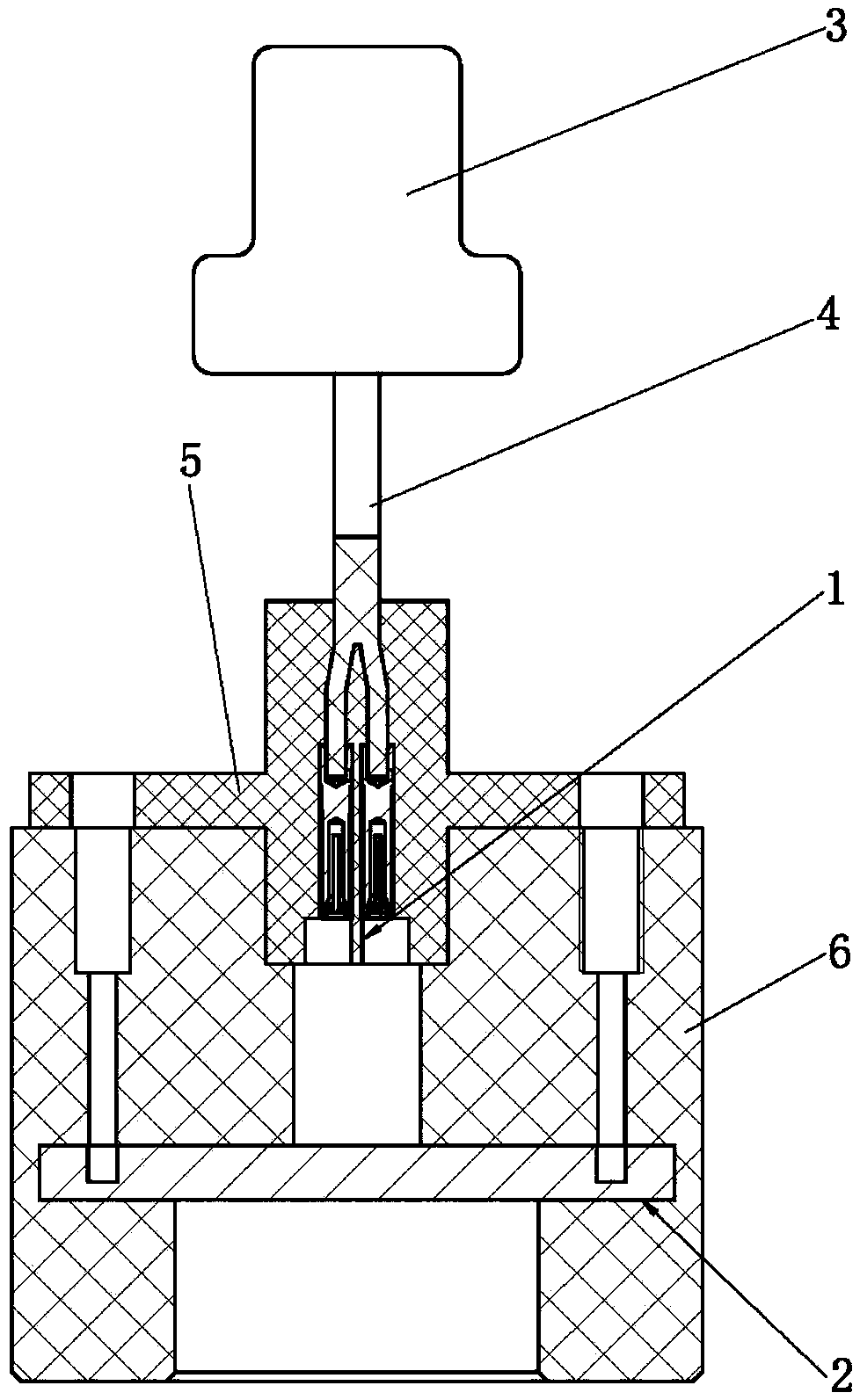

[0033] like figure 1 As shown in the figure, a special adapter cable for the firing of a shock plate detonator, including a detonator 1 and a lead plate 2, including a base inlay 6, a two-pin socket 5 and a plug 3, the base inlay 6 is detachably connected to the two-pin socket 5, and the two-pin socket 5 Connect the plug 3, the two-core socket 5 is used to keep the detonator 1 and the lead plate 2 always vertical, the base inlay 6 is used to keep the lead plate 2 horizontal when it is impacted, and the plug 3 is connected to the experimental socket.

[0034] like figure 2 As shown, specifically, the plug 3 is provided with a coaxial cable 4 , one end of the coaxial cable 4 is connected to the two-core socket 5 , and the other end of the coaxial cable 4 is connected to the plug 3 .

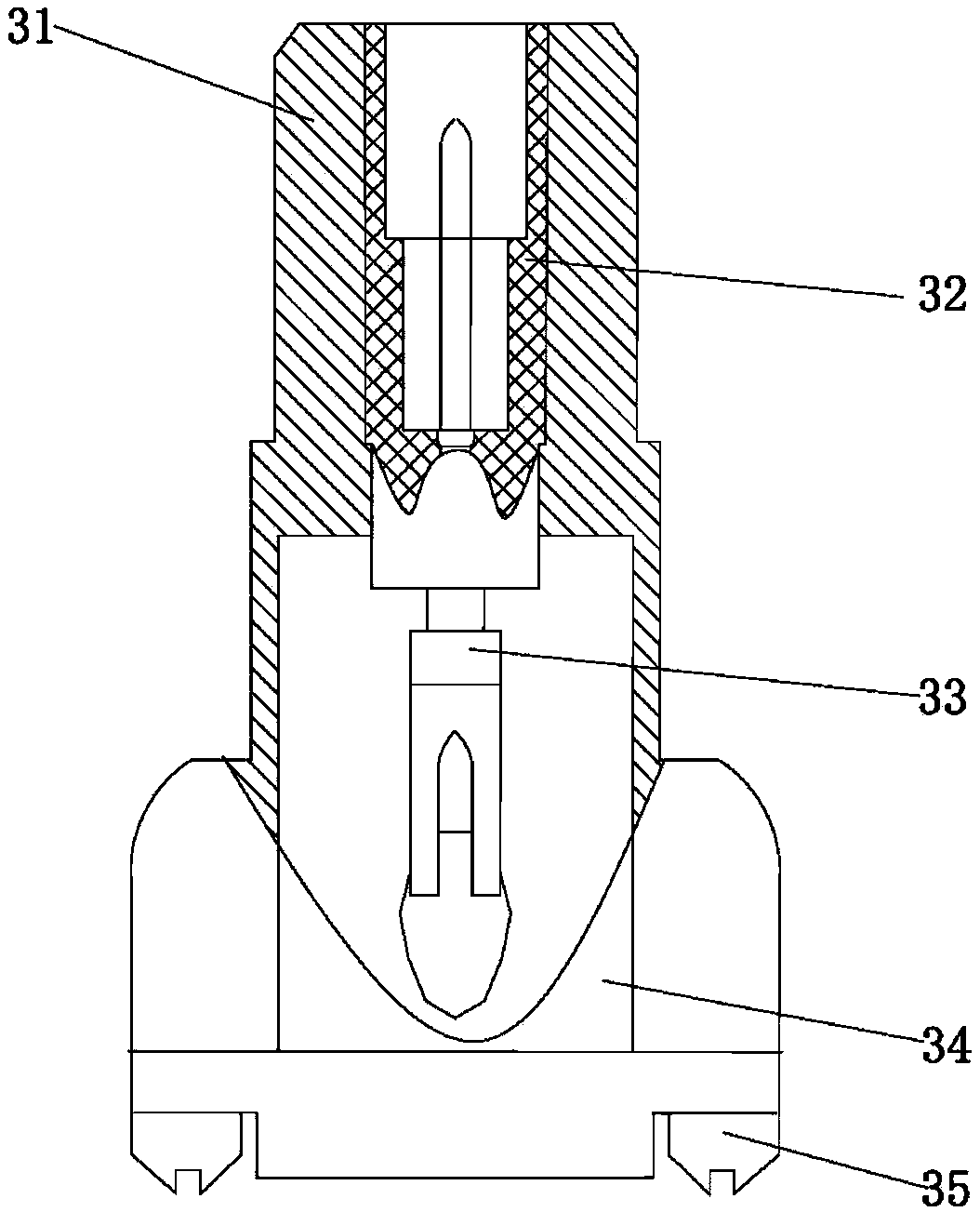

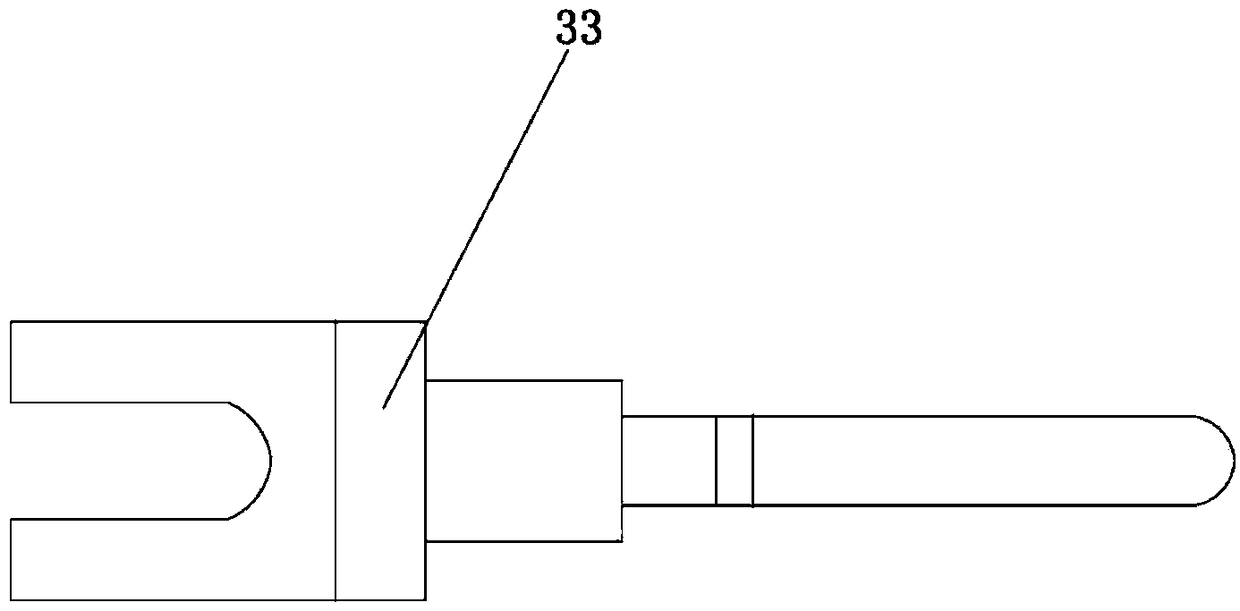

[0035] like image 3 and Figure 4 As shown, the plug 3 includes a housing 31, a mounting plate 32, pins 33, a cover plate 34 and screws 35, the pins 33 are arranged in the mounting plate 32, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com