Weighing tank feeding pipe device and use method thereof

A technology of feed pipe and weighing tank, which is applied in the equipment field of weighing tank feed pipe, and can solve the problems of low performance of exhaust cooling at the exhaust port, long and brittle pipes and shaking, and small relative movement. , to achieve the effect of reducing the communication permission period, reducing the running time, and increasing the use cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

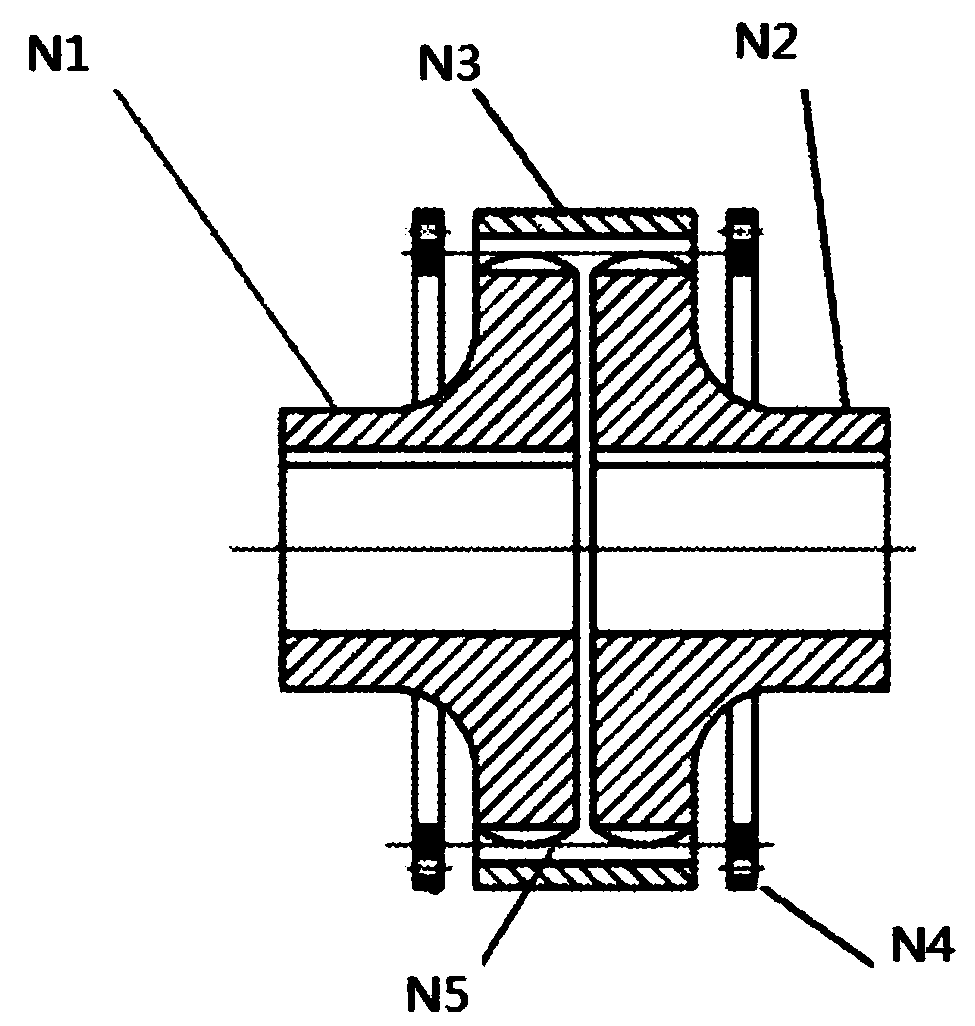

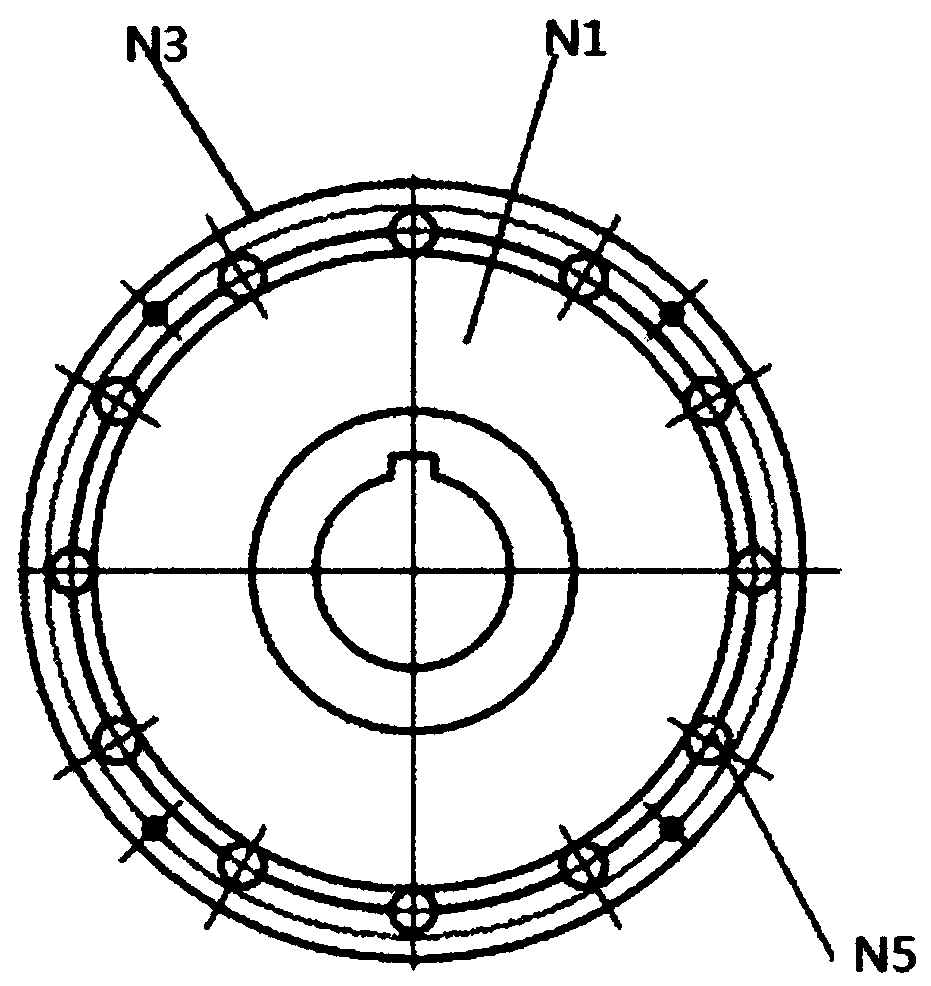

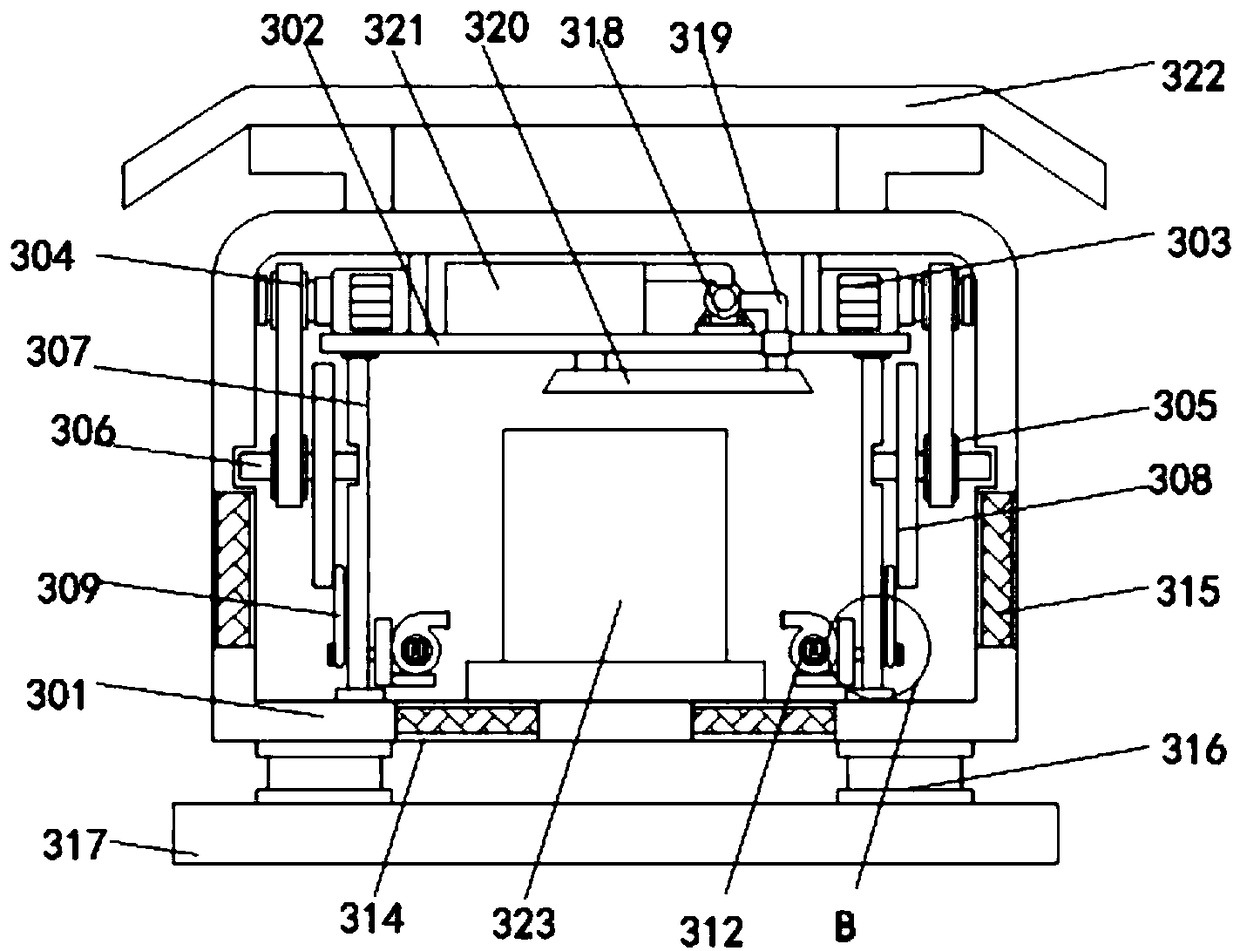

[0071] like Figure 1-Figure 6 As shown, the equipment for the feed pipe of the weighing tank includes such as the application number "201520482689.6", the application date is "2015.07.07" and the patent name is "A lead powder weighing tank feed pipe that is easy to clean foreign matter" The feed pipe of the lead powder weighing tank that is convenient for cleaning foreign matter, the lower end of the feed pipe is connected to the top of the weighing tank, the feed pipe is connected with a vibrating screen device, and the vibrating screen device includes a side through a connecting rod The supporting plate connected to the beam, the supporting plate is provided with a vibration motor and a through hole, the through hole is provided with a filter screen, the feeding pipe is composed of two pipes butted, the supporting plate and the filter screen are clam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com