Supercritical carbon dioxide reactor fuel assembly

A carbon dioxide and fuel assembly technology, which is applied in the control of reactor fuel elements, reactors, and nuclear reactions, etc., to achieve significant effects and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

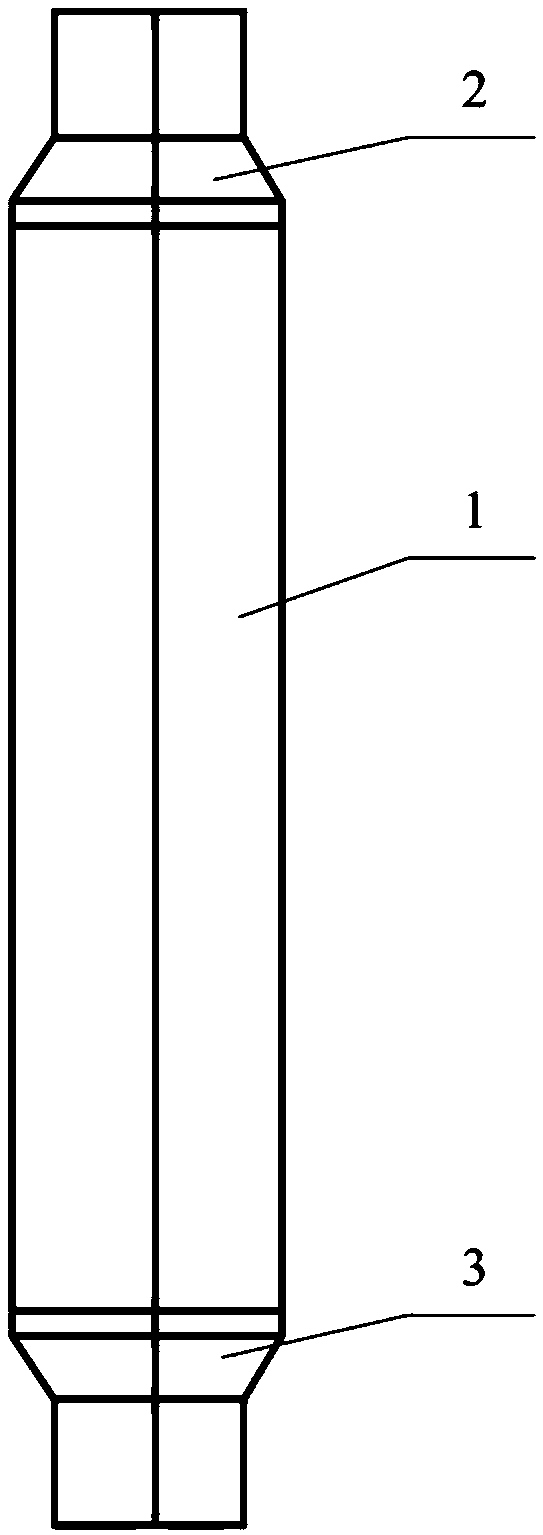

[0031] A supercritical carbon dioxide reactor fuel assembly mainly includes an upper nozzle 1, a fuel core and a lower nozzle 7 arranged sequentially from top to bottom, such as figure 1 shown.

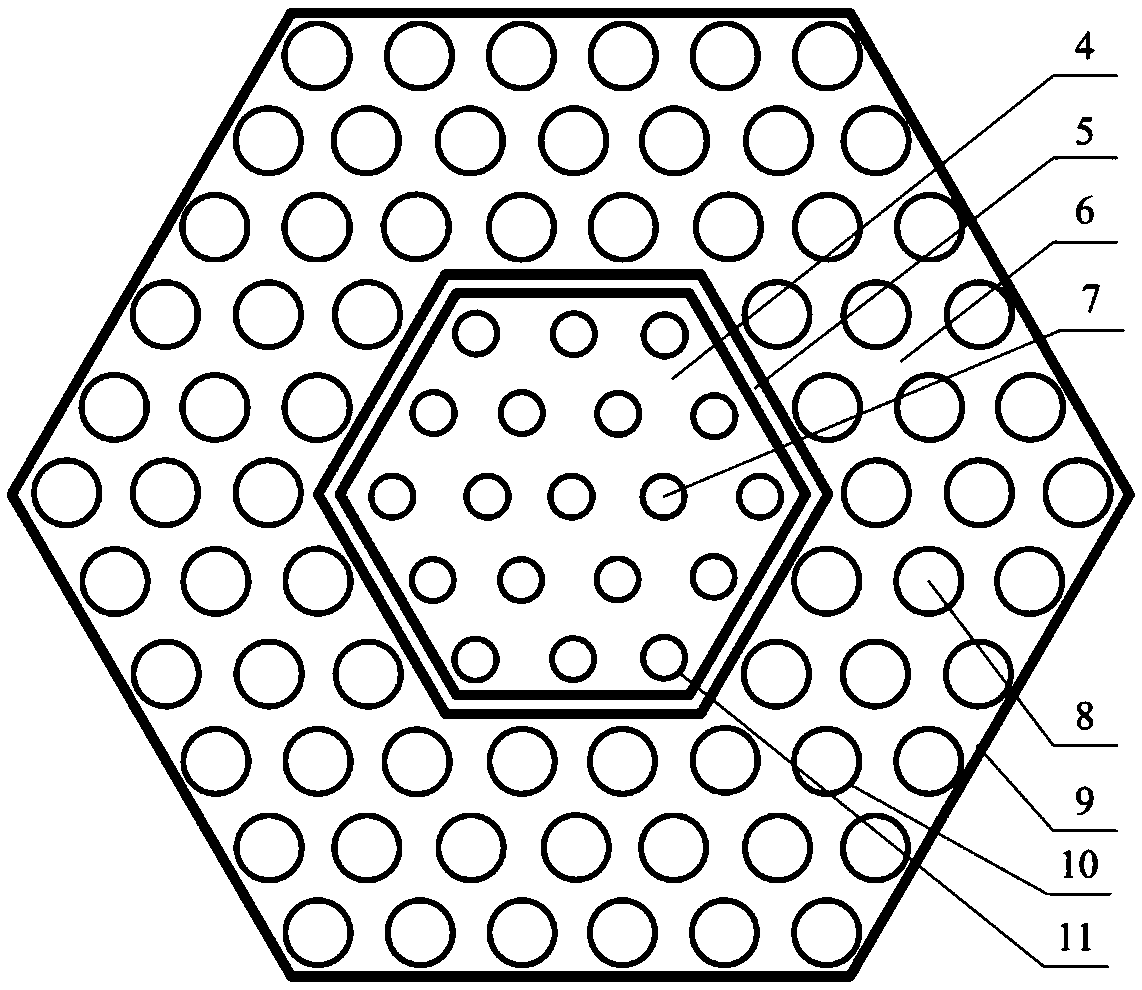

[0032] The fuel core includes a moderator area 4, a thermal insulation and burnable poison area 5, and a fuel area 6 arranged sequentially from the inside to the outside, such as figure 2 shown.

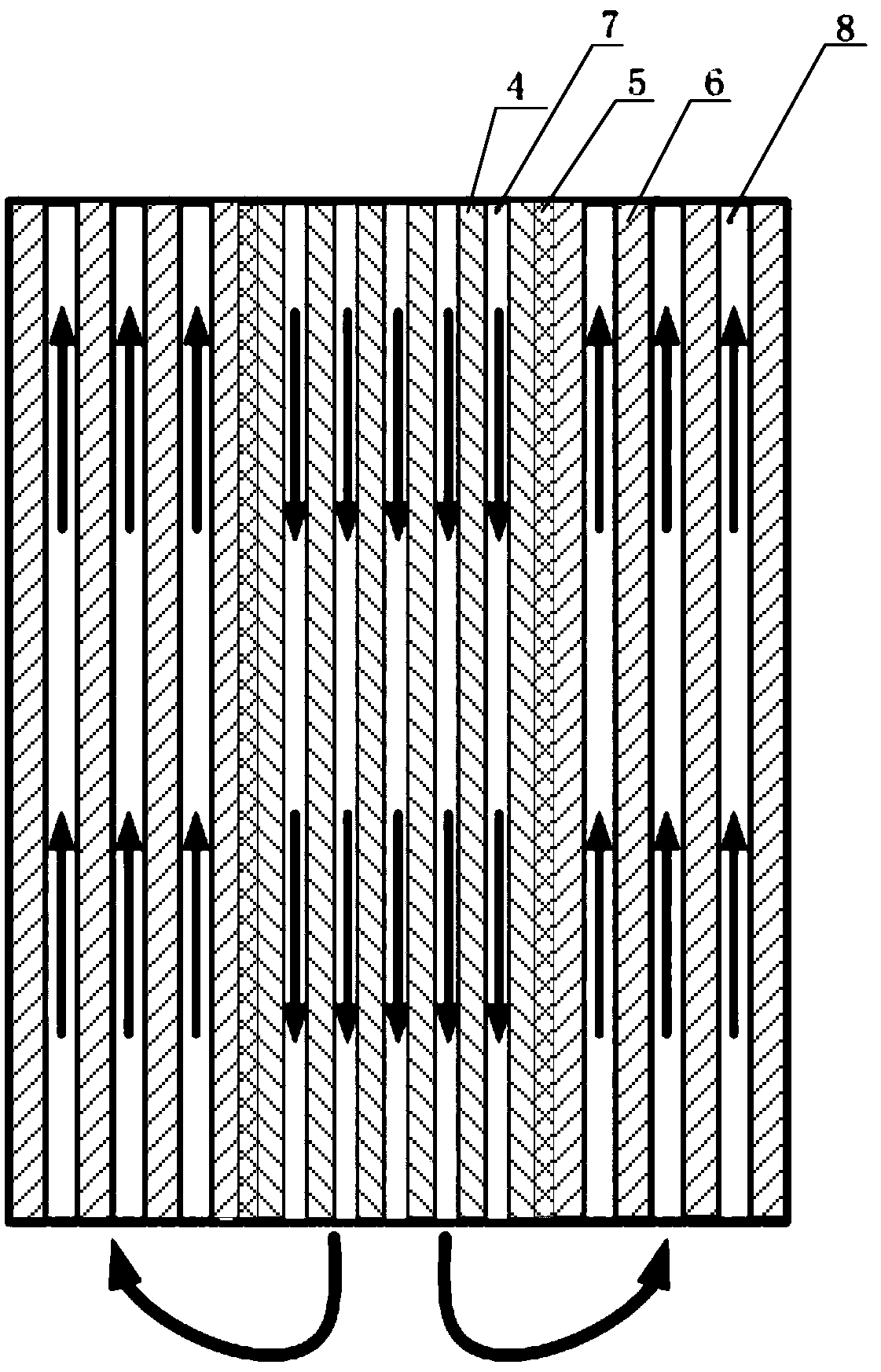

[0033] Moderator cooling holes 7 vertically penetrating the moderator zone 4 are also provided in the moderator zone 4, and fuel coolant holes 8 vertically penetrating the fuel zone 6 are set in the fuel zone 6; Supercritical carbon dioxide first flows through the moderator cooling hole 7 from top to bottom, and then flows through the fuel coolant hole 8 from bottom to top and then is discharged, as image 3 shown.

Embodiment 2

[0035] A supercritical carbon dioxide reactor fuel assembly, mainly comprising a hexagonal prism fuel core body 1, and an upper socket 2 arranged at the upper end of the fuel core body 1 and a lower socket 3 arranged at the lower end of the fuel core body 1, such as figure 1 shown.

[0036] In the present invention, the fuel core 1 is composed of three coaxial hexagonal prisms with different side lengths, the innermost circle is the moderator, the outermost circle is the fuel, and the middle circle layer is heat insulation and combustible poison; that is, the fuel core 1 From the center to the outside, there are moderator area 4, heat insulation and burnable poison area 5, and fuel area 6, such as figure 2 shown.

[0037] The moderator zone 4 is a hexagonal prism with a diameter of 20-22mm, and a moderator cooling hole 7 with a diameter of 3-4mm is opened inside to cool the moderator and control the operating temperature of the moderator zone. Heat insulation and burnable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com