Cable vulcanization method

A technology for cables and cable bundles, applied in the field of cable vulcanization, can solve the problems of weak outlet parts, poor sealing of cable connectors, etc., to increase the vulcanization effect, reduce after-sales costs, improve waterproof and anti-aging performance and environmental suitability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

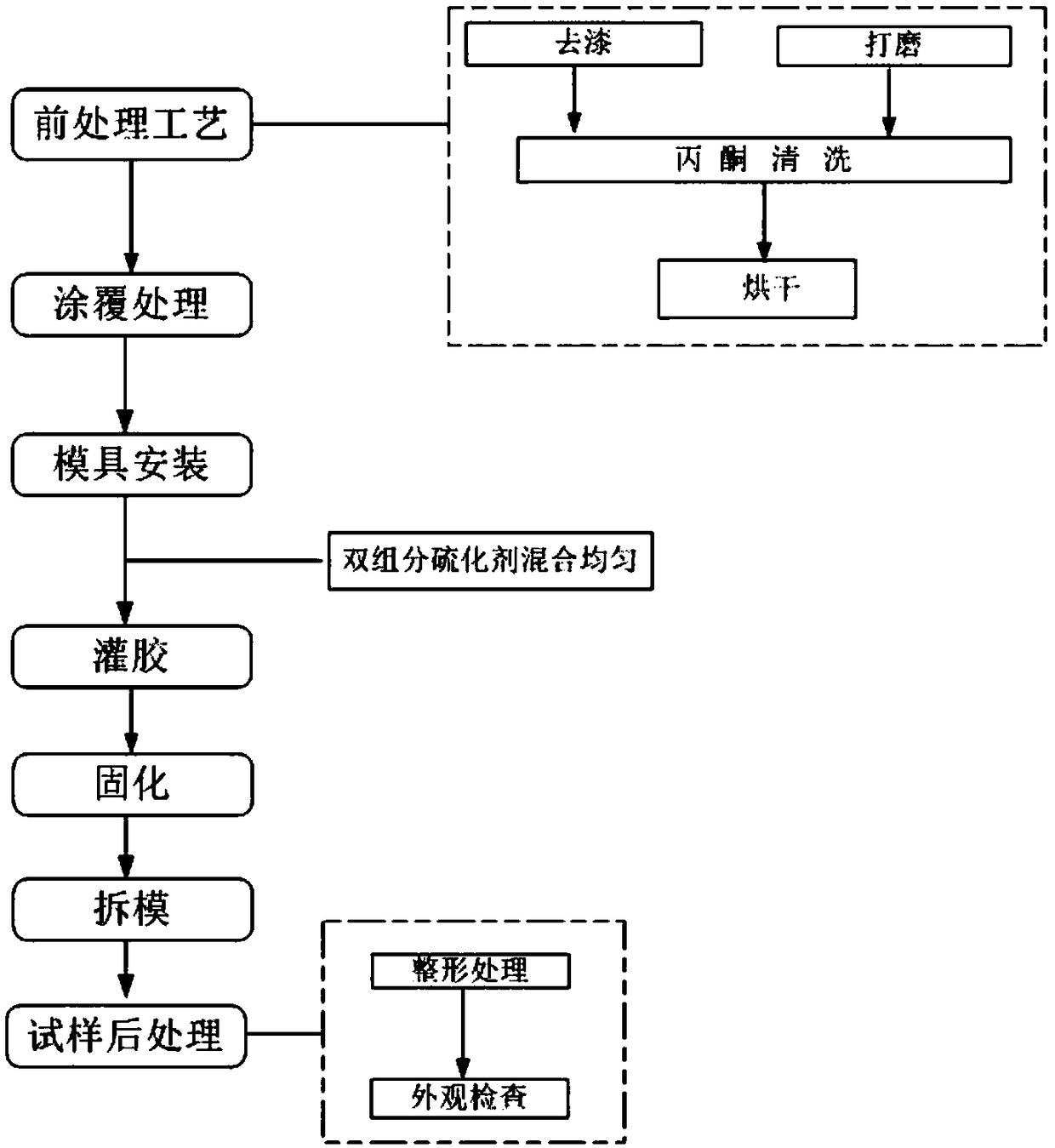

[0073] (1) Pretreatment process: before vulcanization, clean the parts to be vulcanized.

[0074] a. First use a special tool to remove the paint on the outer surface of the outlet of the cable connector; then use a brush to clean the polished powder, requiring no powder and excess residue; then clean the surface to be vulcanized with acetone, after cleaning Blow for two minutes with a heat gun set at 80°C.

[0075] b. First use sandpaper to polish the plastic protective cover on the surface of the cable bundle, so that the surface to be vulcanized has a certain roughness, and the plastic protective cover on the surface of the cable bundle is not damaged; then use a brush to clean the polished powder. There is no powder and excess residue; then clean the surface to be vulcanized with acetone, and after cleaning, set the heat gun at 80°C to blow for two minutes.

[0076] (2) Coating treatment

[0077] Dip 401 glue with a paintbrush and evenly coat the surface to be vulcanized...

Embodiment 2

[0091] (1) Pretreatment process: before vulcanization, clean the parts to be vulcanized.

[0092] a. First use a special tool to remove the paint on the outer surface of the outlet of the cable connector; then use a brush to clean the polished powder, requiring no powder and excess residue; then clean the surface to be vulcanized with acetone, after cleaning Blow for two minutes with a heat gun set at 80°C.

[0093] b. First use sandpaper to polish the plastic protective cover on the surface of the cable bundle, so that the surface to be vulcanized has a certain roughness, and the plastic protective cover on the surface of the cable bundle is not damaged; then use a brush to clean the polished powder. There is no powder and excess residue; then clean the surface to be vulcanized with acetone, and after cleaning, set the heat gun at 80°C to blow for two minutes.

[0094] (2) Coating treatment

[0095] Dip RM-1 glue with a paintbrush and evenly coat the surface to be vulcanize...

Embodiment 3

[0109] (1) Pretreatment process: before vulcanization, clean the parts to be vulcanized.

[0110] a. First use a special tool to remove the paint on the outer surface of the outlet of the cable connector; then use a brush to clean the polished powder, requiring no powder and excess residue; then clean the surface to be vulcanized with acetone, after cleaning Blow for two minutes with a heat gun set at 80°C.

[0111] b. First use sandpaper to polish the plastic protective cover on the surface of the cable bundle, so that the surface to be vulcanized has a certain roughness, and the plastic protective cover on the surface of the cable bundle is not damaged; then use a brush to clean the polished powder. There is no powder and excess residue; then clean the surface to be vulcanized with acetone, and after cleaning, set the heat gun at 80°C to blow for two minutes.

[0112] (2) Coating treatment

[0113] Use a paintbrush to dip in Chemlock 218 adhesive and apply evenly on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com