Composite material sandwich structure with built-in fiber grating, monitoring system and method

A fiber grating and composite material technology, applied in chemical instruments and methods, measuring devices, instruments, etc., can solve the problems of structural failure, complicated measurement, and easily damaged sensors, and achieve the effect of easy operation and one-time installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

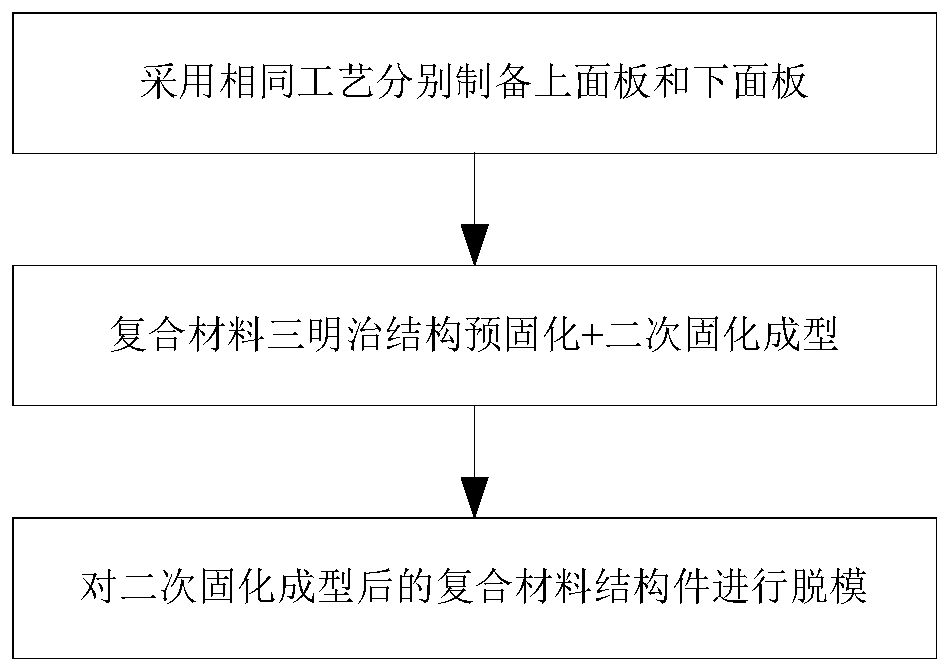

[0059] Such as figure 1 As shown, a method for preparing a composite material sandwich structure with an embedded fiber grating of the present invention includes:

[0060] Step 1: The upper panel and the lower panel are respectively prepared by the same process.

[0061] Specifically, the specific process of preparing the upper panel and the lower panel includes:

[0062] Step (1.1): machining lead grooves on the surface of the side wall plate of the mould.

[0063] In a specific implementation, it also includes: completely covering each surface of the lead groove with a polymer film.

[0064] In this way, the sliding between the polymer film and the surface of the lead groove makes it easier to separate the lead groove from the mold.

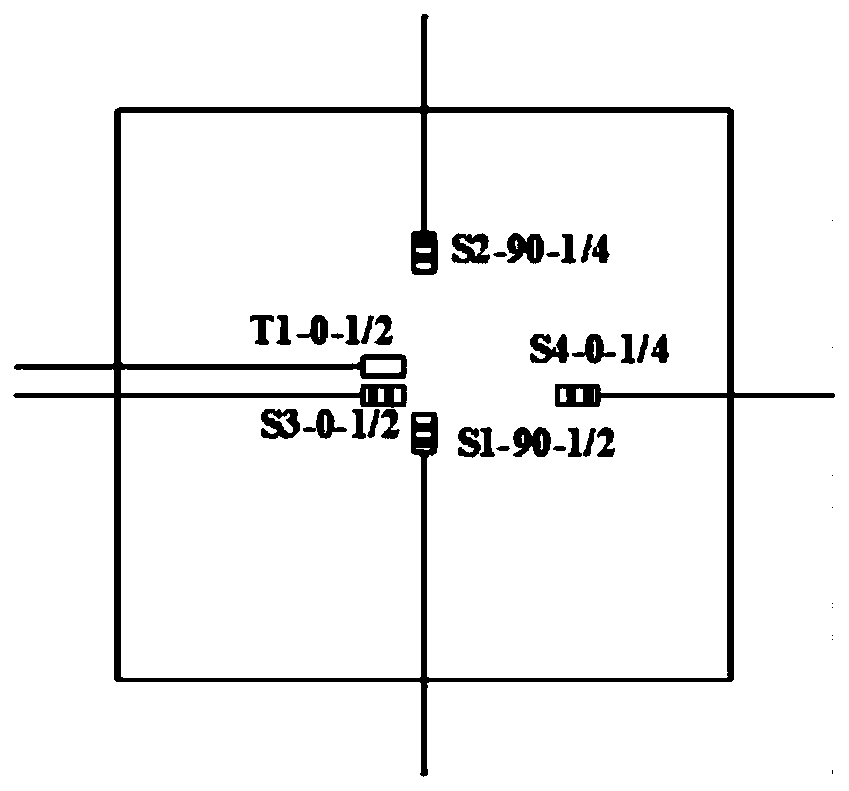

[0065] Preferably, the lead groove is arranged at 1 / 2 or 1 / 4 length distance of the mold frame.

[0066] It should be noted that, according to the actual situation, the lead groove can also be arranged at other positions of the mold frame. ...

Embodiment 1

[0104] In Embodiment 1, a hot molding press is used to solidify and form a composite material sandwich structure, and the specific process is as follows:

[0105] (1) Process lead grooves with a width of 10 mm and a depth of 1.5 mm at 1 / 2 and 1 / 4 of each side of the square mold frame.

[0106] (2) Cover all sides of the mold frame with three layers of high-temperature-resistant PTFE film, so that the PTFE film and the mold frame are tightly attached; each lead groove is also covered with PTFE film .

[0107] (3) Cut the carbon fiber prepreg in a direction parallel to the fiber direction (0° direction), perpendicular to the fiber direction (90° direction), and 45° to the fiber axis, with an in-plane size of 300mm*300mm; cut out the same size Honeycomb core layer, the thickness of the core layer is 12.75mm.

[0108] (4) Prepare the fiber grating sensor, check whether the sensor is damaged and calibrate it. Multiple grating regions are distributed on the optical fiber of each ...

Embodiment 2

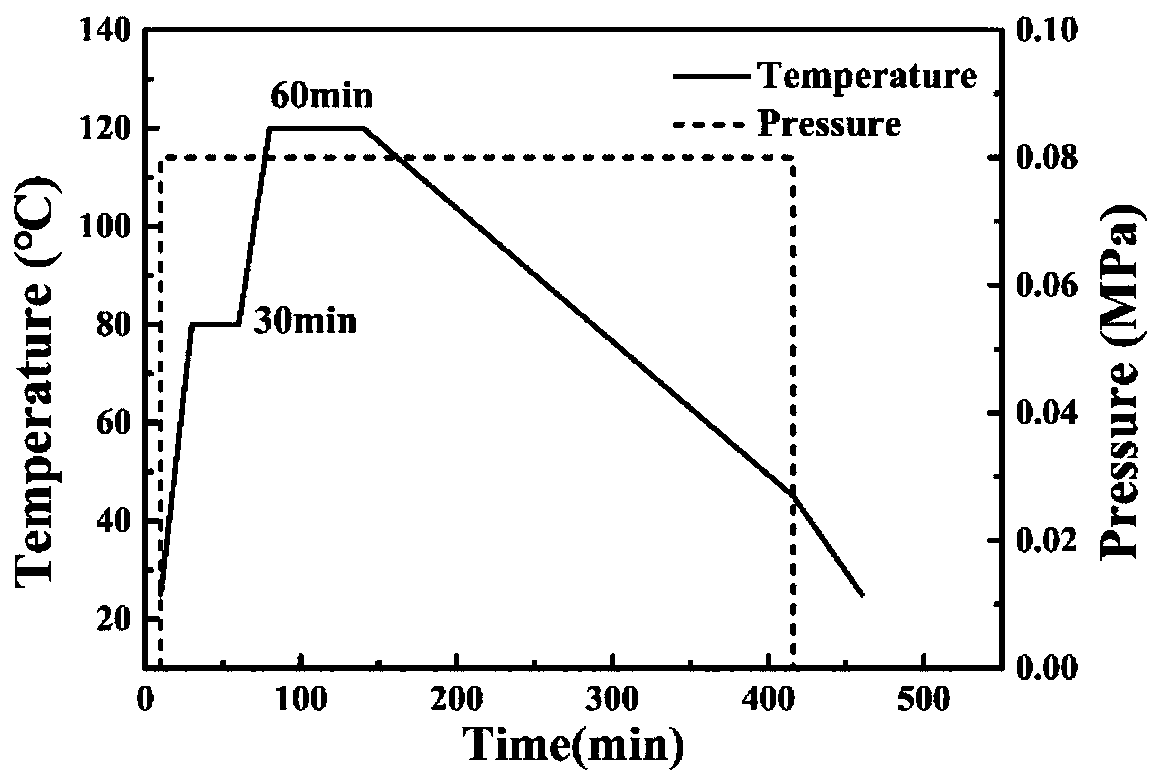

[0116] In Example 2, an autoclave is used to solidify and form the sandwich structure of the composite material, and the specific process is as follows:

[0117] (1) Cut the prepreg cloth to the corresponding size according to the preset layup method, coat the mold with release wax, lay the carbon fiber prepreg, and embed the fiber grating sensor according to the experimental plan.

[0118] (2) Paste the isolation film on the upper and lower sides of the carbon fiber prepreg layer, and then lay a release cloth and a suction felt on the upper part of the prepreg in sequence, and finally seal it with a sealing bag.

[0119] (3) Send the car with the prepreg layer into the autoclave, close the tank door and safety interlock, and open the air valve and water valve.

[0120] (4) Turn on the computer used for monitoring and set the pressure and temperature curves, and then turn on the automatic control system of the autoclave.

[0121] (5) After the curing experiment is completed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com