Dyeing and finishing process of elastic blended fabric

A technology of blended fabrics and elasticity, applied in the dyeing and finishing process of elastic blended fabrics, can solve the problems of too simple steps, poor dyeing effect, easy color fading, etc., and achieve the effect of avoiding damage and good work stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

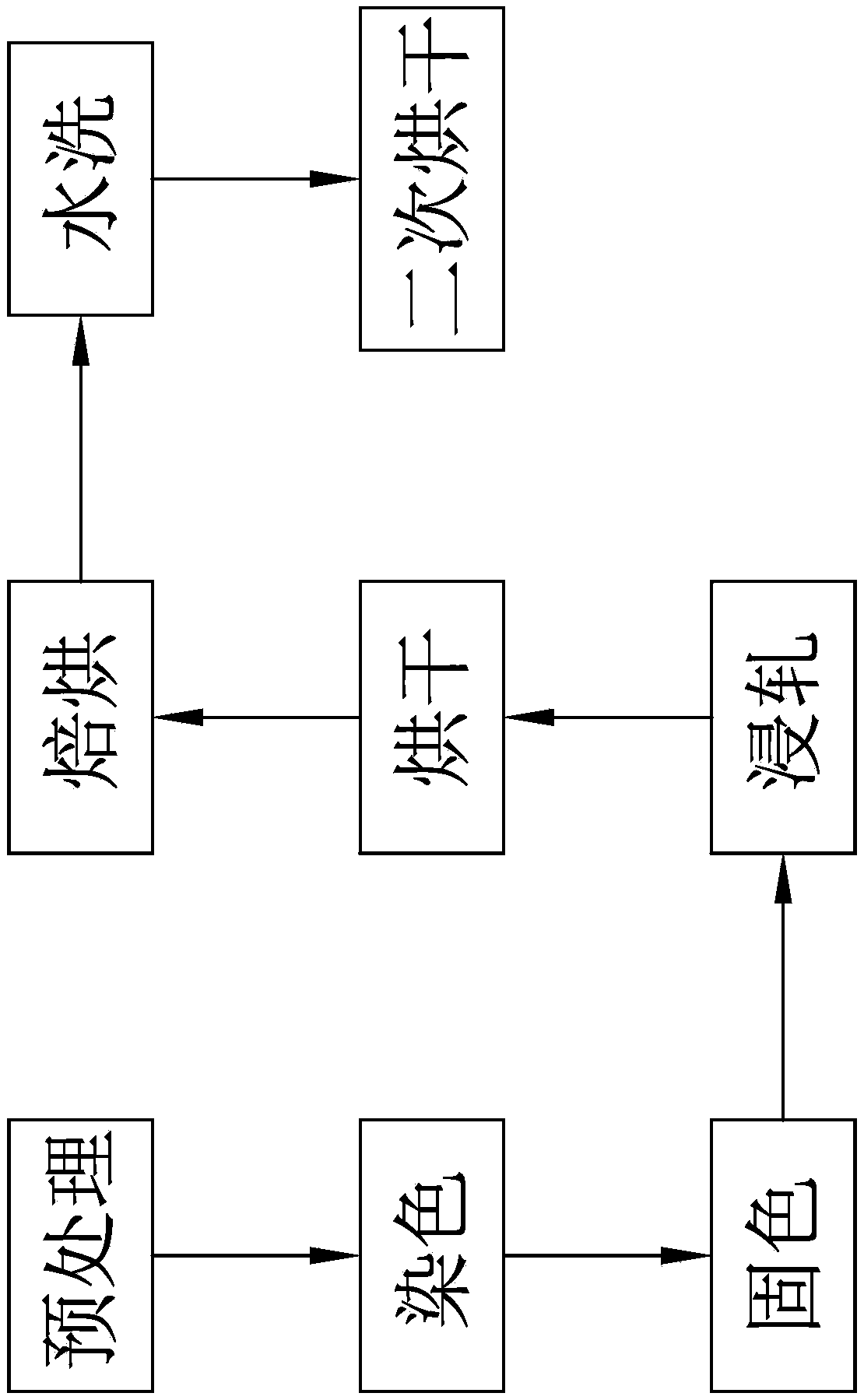

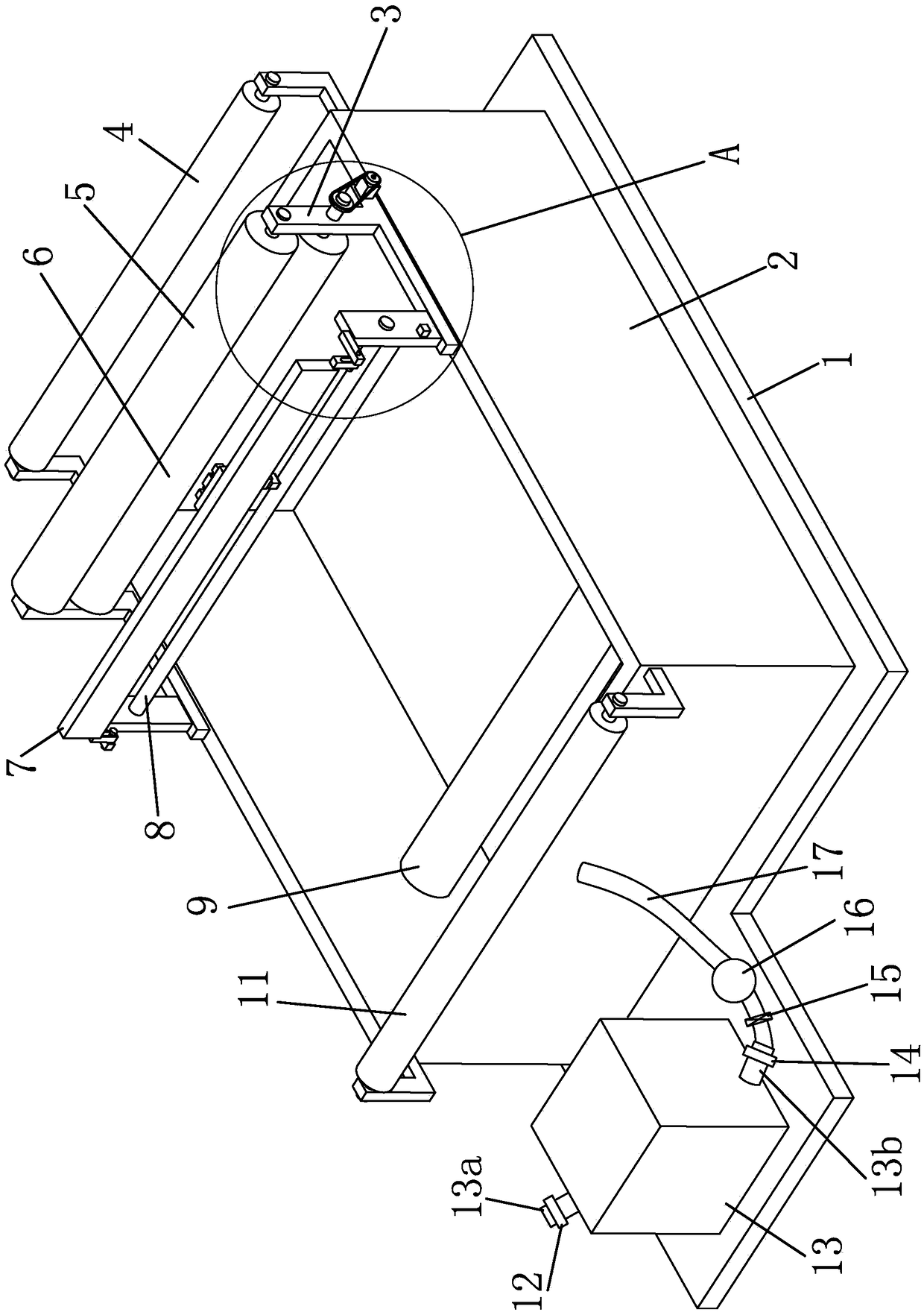

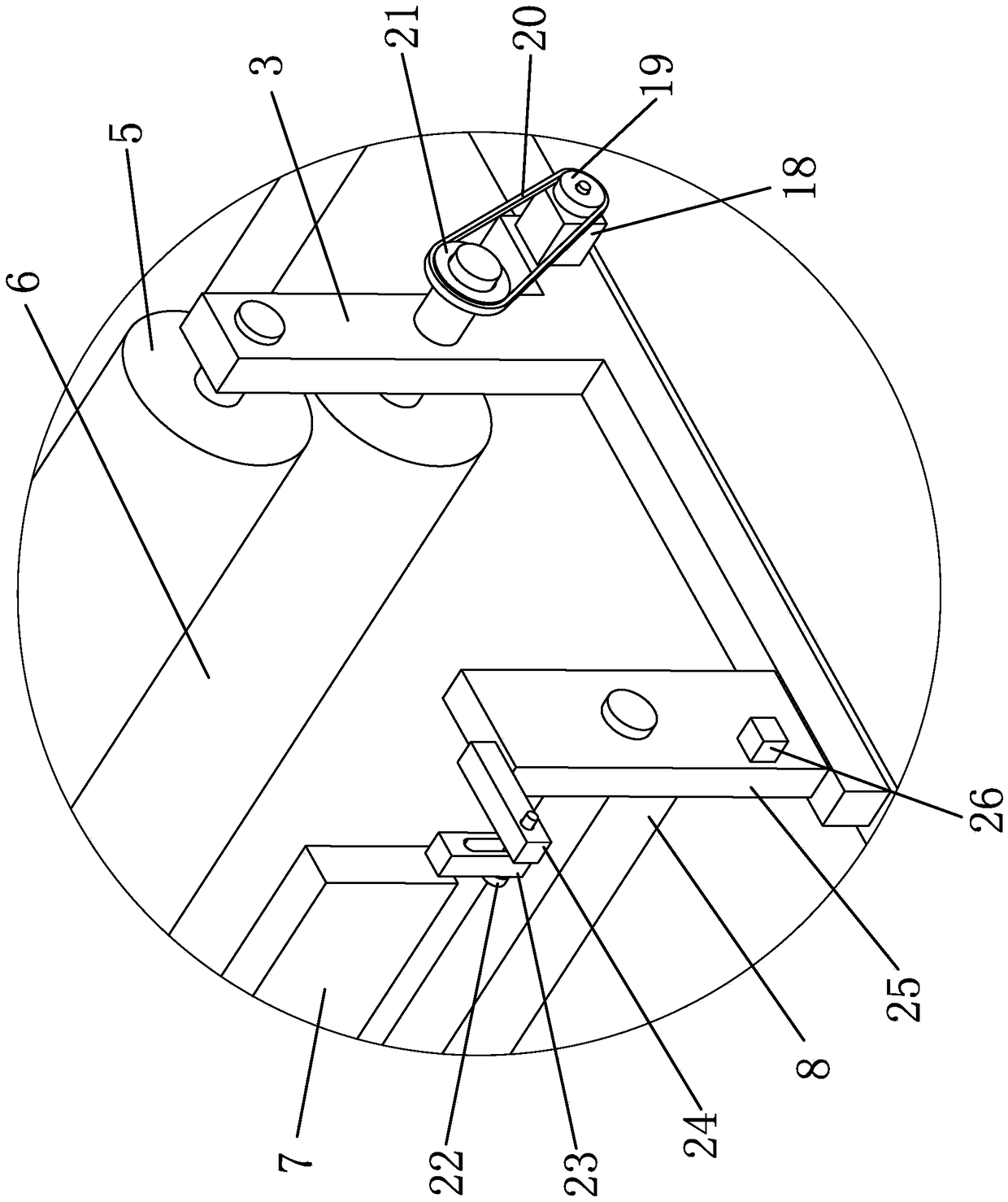

[0058] like figure 1 As shown, the dyeing and finishing process of the elastic blended fabric comprises the following steps: a. pretreatment; b. dyeing; The rolling equipment carries out one dipping and one rolling treatment, and the excess rate is 70-80%; e, drying: put the elastic blended fabric after padding into an oven for drying, and the drying temperature is 80-90°C; f, baking Baking: put the dried elastic blended fabric into a baking machine and bake at a temperature of 110-130°C; g, washing: put the baked elastic blended fabric into a washing machine for washing; h, II Second drying: put the washed elastic blended fabric into an oven for drying at a temperature of 90-100° C.; in this embodiment, the dyeing and finishing process of the elastic blended fabric includes the following steps: a. Treatment; b, dyeing; c, color fixing; d, padding: put the elastic blended fabric after color fixing into the dipping solution and perform one dipping and one rolling treatment thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com