A core sampling drilling rig

A technology of core sampling and drilling rigs, which is applied in the direction of rotary drilling rigs, undisturbed core extraction devices, drilling pipes, etc., can solve the problems of lack of equipment, manpower consumption, and harsh working environment, so as to avoid cumbersome manual operations and achieve high automation. Unique effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

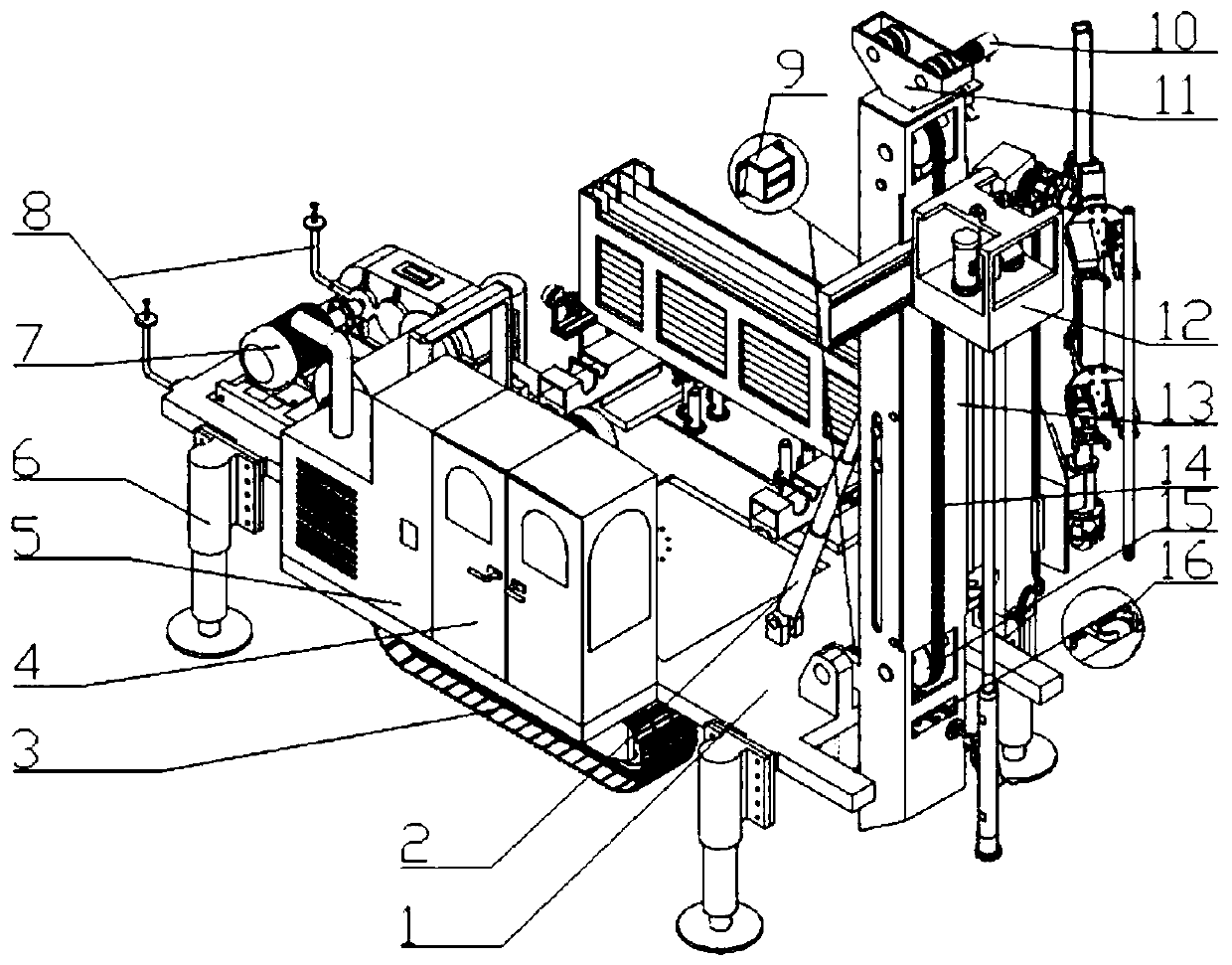

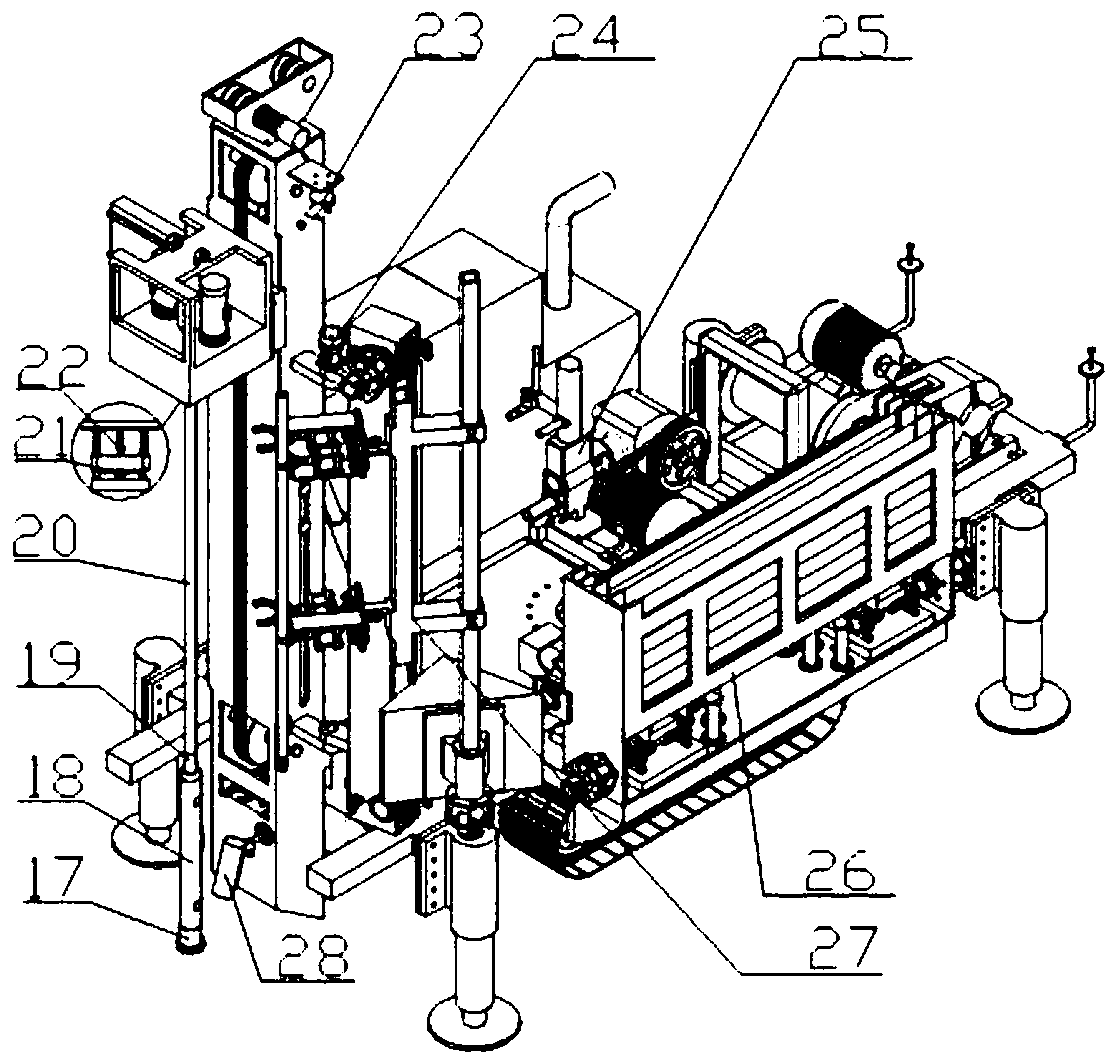

[0040] A core sampling drilling rig, especially an automatic fully hydraulic core drilling rig, including a main frame 1, a mast lifting cylinder 2, a crawler chassis 3, a control room 4, a control cabinet 5, a support leg 6, a hoist assembly 7, and a fixed pulley goose Head 11, power head 12, mast 13, clamping manipulator assembly 16, diamond drill bit 17, core pipe 18, drill pipe 20, mud pump assembly 25, automatic rod feeding mechanism 26 and automatic rod taking mechanism 27, diamond drill bit 17 passes through the core The pipe 18 and the core pipe adapter 19 are arranged on the drill pipe 20, and the drill pipe 20 is arranged on the power head 12, see Figure 1-Figure 5 .

[0041] The crawler chassis 3 and the supporting legs including the supporting legs 6 (hydraulic legs) form a traveling mechanism, which is arranged on the main frame 1 to drive the whole core sampling drilling rig to move.

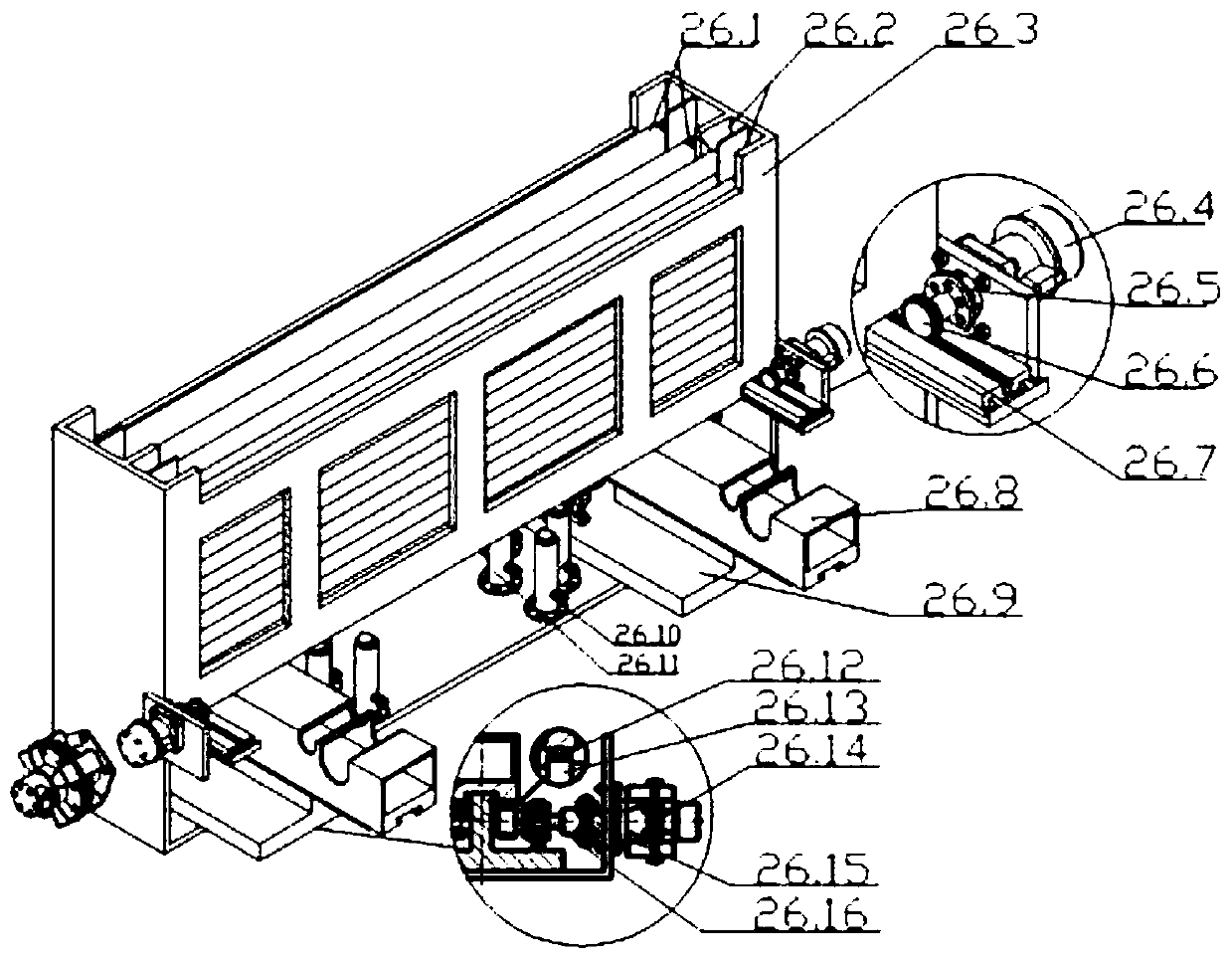

[0042] Described automatic rod-feeding mechanism 26 sees for details figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com